Belajar PLC | Pengenalan Programmable Logic Controller #1

Summary

TLDRThis educational video introduces Programmable Logic Controllers (PLCs), exploring their history, functionality, and industrial applications. The script explains the evolution of PLCs from early relay systems, highlighting their flexibility, faster response times, and simplified wiring. It covers various PLC types, such as compact and modular, and their role in industries like power plants, robotics, and manufacturing. The video also touches on PLC programming standards (IEC 61131-3) and tools used for programming, including PCs, laptops, and handheld programmers. Overall, it provides a beginner-friendly foundation for understanding PLCs in industrial automation.

Takeaways

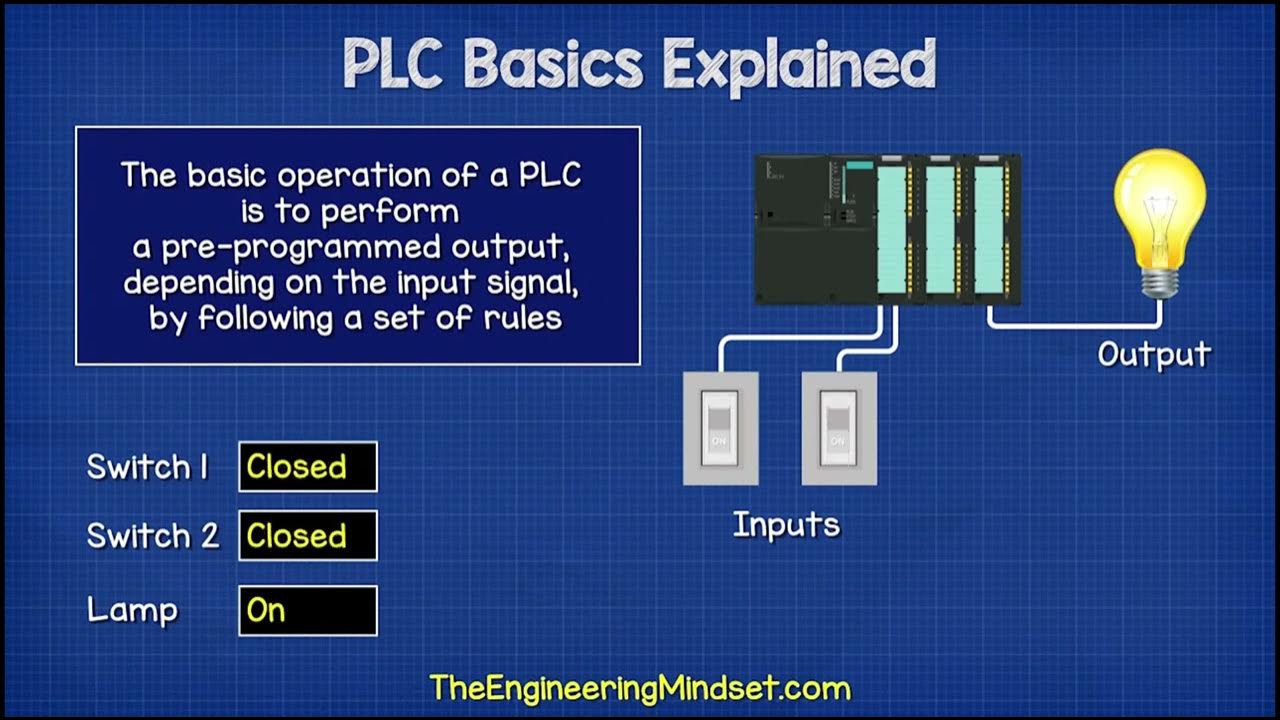

- 😀 PLC stands for Programmable Logic Controller, a device used to control and monitor industrial equipment.

- 😀 PLC can be easily reprogrammed to suit different tasks, offering flexibility compared to traditional relay systems.

- 😀 The history of PLCs dates back to 1968 when the Modular Digital Controller (MODICON) was first introduced.

- 😀 PLCs have revolutionized industrial automation, replacing less flexible and difficult-to-update relay-based systems.

- 😀 PLC systems are widely used in various industries, including power plants, robotics, oil and gas, and manufacturing.

- 😀 The main components of a PLC include the CPU, which processes data, and the input/output modules for signal exchange.

- 😀 PLCs offer real-time response, with many models handling input/output in milliseconds, and some even in microseconds.

- 😀 PLCs come in two types: Compact PLCs with fixed I/O configurations and Modular PLCs with scalable I/O for larger applications.

- 😀 The IEC 61131-3 standard outlines programming languages for PLCs, including Ladder Logic, Function Block Diagram, and more.

- 😀 PLC programs can be easily transferred between different models and vendors, allowing for integration across various systems.

Q & A

What does PLC stand for, and what is its main function?

-PLC stands for Programmable Logic Controller. It is a device designed to control and monitor industrial production equipment, such as machinery, and to automate processes in manufacturing plants or facilities.

Why was the PLC developed, and how does it differ from the relay control systems?

-PLC was developed to replace relay-based control systems, which were considered less flexible and difficult to update. PLCs are more versatile, programmable, and allow for easier adjustments without the need for rewiring or physical changes, making them more efficient for automation.

What are the primary components of a PLC?

-The main components of a PLC are the CPU (Central Processing Unit), input and output modules, memory, and connected input/output devices like sensors and actuators. These components work together to process data and control industrial systems.

How does the history of PLC development unfold?

-PLC development began in 1968 when Richard Morlay, an engineer at Bedford Associates, created the Modicon digital controller. By 1982, the IC 6131 strip 3 was introduced as the standard for PLC software development, and during the 1980s, the use of machine interfaces (HMIs) became more common.

What are the advantages of using PLC over relay-based systems in industrial automation?

-PLCs are more flexible, allowing for easy reprogramming to meet changing needs without physical rewiring. They are simpler to install, reduce wiring errors, and provide faster response times, making them more efficient and cost-effective than relay systems.

What are the two types of PLCs, and how do they differ?

-PLCs are categorized into two types: compact and modular. Compact PLCs have a fixed number of I/O (Input/Output) channels and are suitable for smaller projects. Modular PLCs, on the other hand, have separate components like CPU and I/O modules, allowing for greater flexibility and scalability, especially in larger applications.

What programming languages are typically used for PLC programming?

-PLC programming typically uses the IEC 61131-3 standard, which includes five programming languages: Ladder Diagram, Function Block Diagram, Structured Text, Instruction List, and Sequential Function Charts. These languages ensure compatibility across different PLCs from various manufacturers.

What types of signals can PLCs handle for input and output?

-PLCs can handle digital signals (with two values: 1 or 0), analog signals (which can change continuously), and periodic pulse signals. These inputs and outputs are used to control various equipment and monitor parameters in industrial systems.

How do PLCs communicate with external devices for program transfer?

-PLCs communicate with external devices, such as PCs or laptops, via serial communication for program upload and download. Additionally, handheld programmers can be used for program transfer, though they are less common due to their limited compatibility and functionality.

What is the role of HMI in PLC systems, and how has it evolved over time?

-HMIs (Human-Machine Interfaces) allow operators to interact with PLCs. Initially, control panels used many physical buttons, but over time, touchscreens have replaced these, making the interaction more efficient and user-friendly, especially in modern PLC systems.

Outlines

Cette section est réservée aux utilisateurs payants. Améliorez votre compte pour accéder à cette section.

Améliorer maintenantMindmap

Cette section est réservée aux utilisateurs payants. Améliorez votre compte pour accéder à cette section.

Améliorer maintenantKeywords

Cette section est réservée aux utilisateurs payants. Améliorez votre compte pour accéder à cette section.

Améliorer maintenantHighlights

Cette section est réservée aux utilisateurs payants. Améliorez votre compte pour accéder à cette section.

Améliorer maintenantTranscripts

Cette section est réservée aux utilisateurs payants. Améliorez votre compte pour accéder à cette section.

Améliorer maintenantVoir Plus de Vidéos Connexes

1. Berkenalan Dengan Kerja Perangkat Kontrol PLC

What is a PLC?...and a PAC?!?

PLC Basics | Programmable Logic Controller

Programable Logic Controller Basics Explained - automation engineering

Introduction to Industrial Automation | Introduction and History

AWAL BELAJAR Ngobrol Santai Tentang PLC (Programmable Logic Controller)

5.0 / 5 (0 votes)