Case Hardening and 6 Types of Case Hardening || Heat Treatment Process

Summary

TLDRThe video script discusses various processes involved in the heat treatment of materials, particularly focusing on 'case hardening' techniques used in the metallurgical industry. It explains the importance of carbon content in steel and how different processes like quenching, tempering, and martempering affect the hardness and properties of the material. The script also introduces modern methods such as induction hardening and flame hardening, highlighting their precision and efficiency in selective hardening of specific areas of a metal part. The aim is to provide a comprehensive understanding of these processes for those interested in metallurgy or seeking to advance their knowledge in material treatment.

Takeaways

- 😀 The video script discusses various processes related to 'case hardening' in the context of metalworking, specifically for Air India's module.

- 🔧 The script explains the importance of not making the entire material hard but only the surface, which is crucial for certain applications requiring specific properties on the surface.

- ⚙️ It introduces the 'case hardening' process, which involves treating the surface of a material to make it hard while leaving the core soft and ductile.

- 🛠️ The video mentions different types of case hardening processes, such as carburizing, nitriding, and induction hardening, each with specific applications and outcomes.

- 👷♂️ The script emphasizes the need for precision in these processes, as the percentage of carbon and other elements can significantly affect the hardness and performance of the material.

- 🔬 It details the steps involved in case hardening, including heating, quenching, and tempering, which are essential for achieving the desired material properties.

- 🔨 The video describes the challenges in case hardening, such as the difficulty of hardening low carbon steel and the strategies to overcome these challenges.

- 🌡️ Temperature control is highlighted as a critical factor in the success of case hardening processes, with specific temperature ranges mentioned for different treatments.

- 🕒 Time is another crucial element in these processes, with the script mentioning that the duration of exposure to heat and other treatments can vary widely.

- 🔉 The script calls for audience interaction by asking viewers to comment on the video and suggest topics for future videos, indicating an engaging and community-driven approach.

- 📚 Lastly, the video promotes an online training program for those interested in advancing their knowledge and skills in the field of metalworking and case hardening processes.

Q & A

What is the main topic of the video script?

-The main topic of the video script is about the process of 'case hardening' in metallurgy, specifically discussing various techniques and their applications.

What does the term 'case hardening' refer to in the context of the script?

-In the context of the script, 'case hardening' refers to a heat treatment process used to harden the surface of a metal while keeping the core soft and ductile.

What are the different types of case hardening processes mentioned in the script?

-The script mentions several types of case hardening processes including carbonitriding, nitriding, induction hardening, and flame hardening.

Why is it necessary to connect with the social platforms mentioned in the script?

-It is necessary to connect with the social platforms to stay updated with the content, engage with the community, and be part of the quality improvement journey of 'Quality of India'.

What is the purpose of using different case hardening processes for different applications?

-Different case hardening processes are used for different applications to meet specific material requirements, such as hardness, wear resistance, and ductility, depending on the functional needs of the part.

What is the significance of the carbon percentage in steel for case hardening processes?

-The carbon percentage in steel is significant for case hardening processes because it affects the hardness and wear resistance of the surface. Lower carbon content may require more effort to achieve the desired hardness.

How does the script describe the use of ammonia gas in the nitriding process?

-The script describes the use of ammonia gas in the nitriding process as a way to expose the steel to nitrogen. When heated, ammonia decomposes into hydrogen and nitrogen, with the nitrogen diffusing into the steel and creating a hard surface layer.

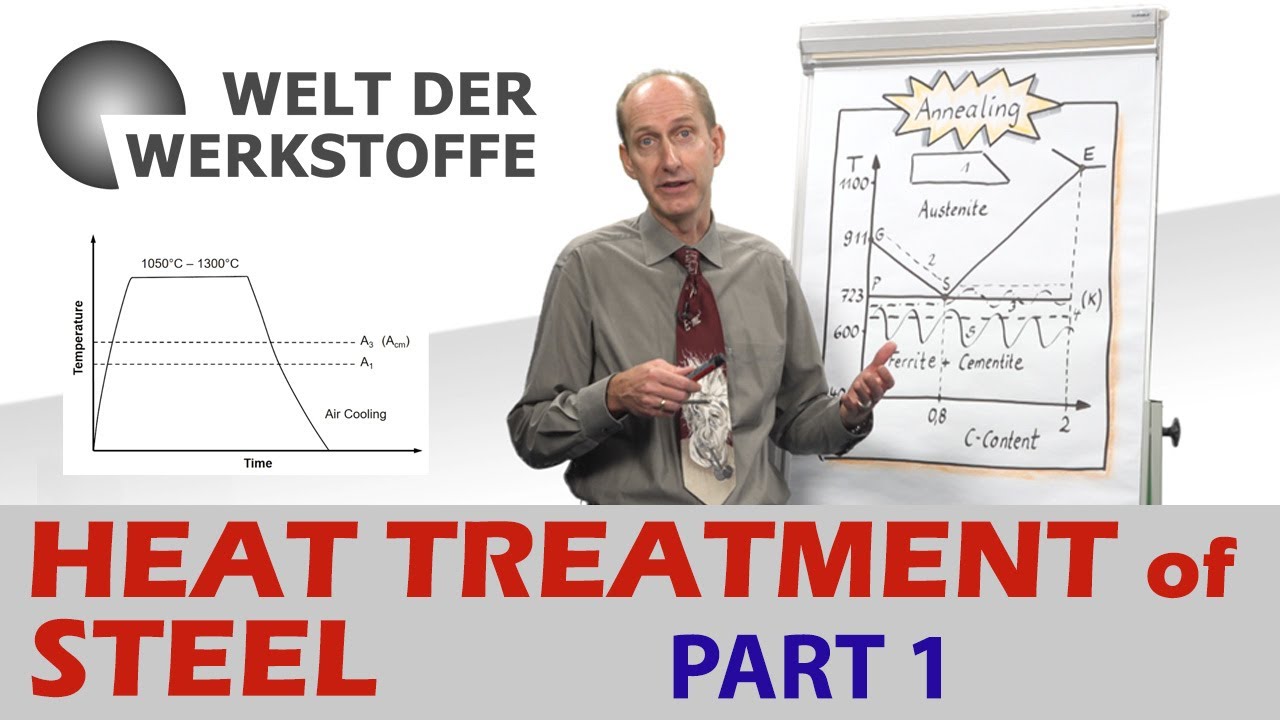

What is the role of temperature in case hardening processes as discussed in the script?

-Temperature plays a crucial role in case hardening processes. It affects the diffusion rate of elements like carbon and nitrogen into the metal, and it determines the hardness and depth of the hardened layer.

What are the key factors to consider for a successful case hardening process according to the script?

-The key factors for a successful case hardening process, as mentioned in the script, include temperature control, time of exposure, and the specific requirements of the material being treated.

How does the script differentiate between the needs of different materials during case hardening?

-The script differentiates between the needs of different materials by discussing how the carbon content and the specific properties of the steel, such as its hardness and ductility, influence the case hardening process and the resulting surface properties.

What is the importance of the 'not case hardening' process mentioned in the script?

-The 'not case hardening' process is important for applications where full hardness is not required. It allows for selective hardening of specific surfaces, providing the necessary properties like wear resistance while maintaining ductility in other areas.

Outlines

此内容仅限付费用户访问。 请升级后访问。

立即升级Mindmap

此内容仅限付费用户访问。 请升级后访问。

立即升级Keywords

此内容仅限付费用户访问。 请升级后访问。

立即升级Highlights

此内容仅限付费用户访问。 请升级后访问。

立即升级Transcripts

此内容仅限付费用户访问。 请升级后访问。

立即升级5.0 / 5 (0 votes)