Heat Treatment || Metallurgy || Materials Science

Summary

TLDRThis video introduces heat treatment processes, explaining how heating, holding, and cooling methods alter the properties of materials like metals and alloys. Key techniques such as annealing, normalizing, hardening, and tempering are explored, with a focus on their effects on strength, ductility, residual stress relief, and grain structure. The video also covers the role of quenching mediums like water, oil, and air in influencing material properties, making it a comprehensive guide for understanding how heat treatment enhances materials for industrial applications.

Takeaways

- 😀 Heat treatment is a process of heating and cooling materials, usually metals or alloys, under controlled conditions to alter their properties or microstructure.

- 😀 The heat treatment process involves three main stages: heating, holding, and cooling. The rates of heating, the duration of holding, and the type of cooling can all be controlled.

- 😀 The main purpose of heat treatment is to improve the mechanical, physical, and chemical properties of materials for various applications.

- 😀 Heat treatment processes can relieve residual stresses introduced during manufacturing processes, such as severe plastic deformation, thereby improving ductility and strength.

- 😀 Different heat treatments alter material properties in various ways. For example, they can improve strength, ductility, resistance to corrosion, and electrical or magnetic properties.

- 😀 The primary heat treatment processes include annealing, normalizing, hardening (or quenching), tempering, and surface case hardening.

- 😀 Annealing involves heating a material to a specific temperature, holding it, and then slowly cooling it to improve ductility, relieve stresses, and refine microstructure.

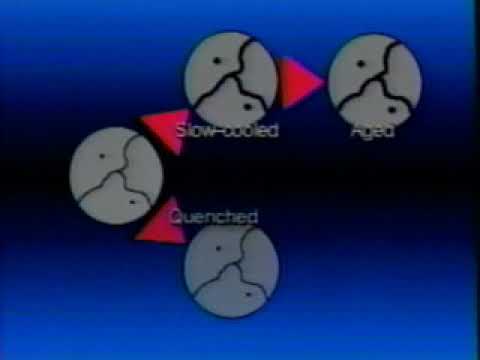

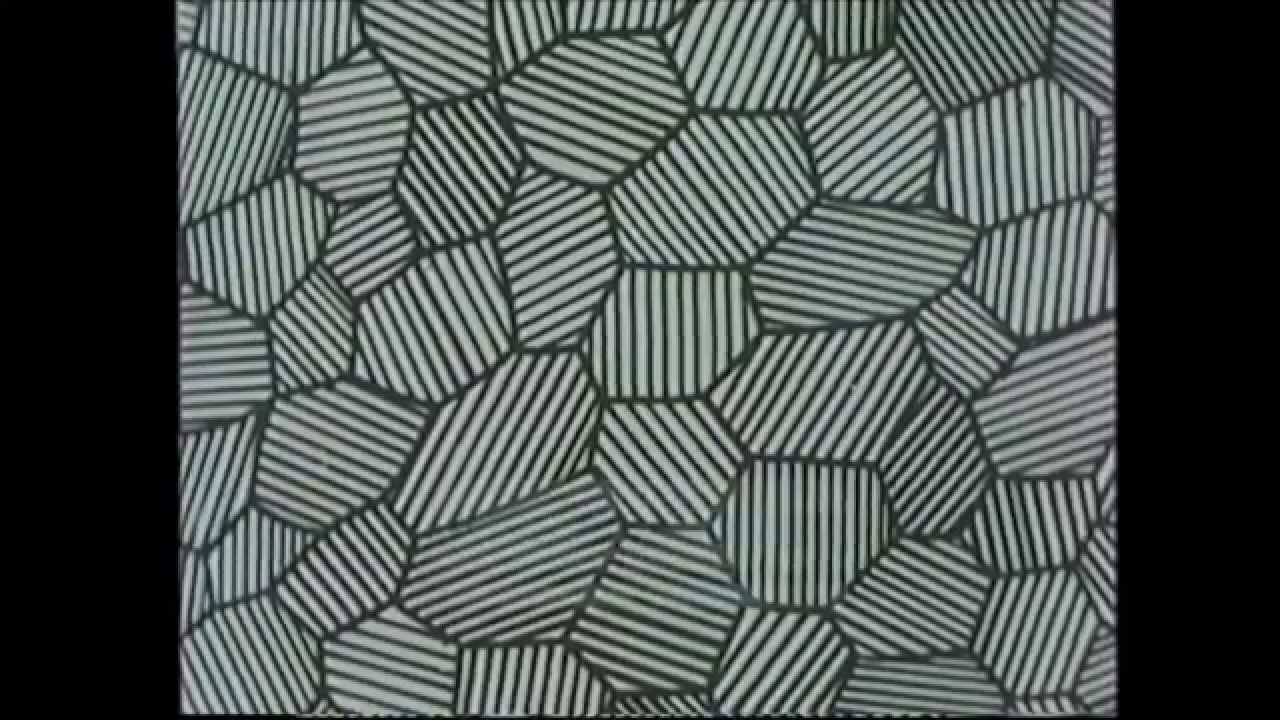

- 😀 Normalizing also involves heating to a critical temperature but differs from annealing in that it uses air cooling, which results in a finer grain structure and higher strength.

- 😀 Hardening or quenching is achieved by heating material to a high temperature and then rapidly cooling it, often in water, oil, or brine, to form a martensitic structure that increases hardness.

- 😀 Tempering is a heat treatment performed after hardening, where the material is reheated to a lower temperature to improve ductility and toughness while relieving stresses.

- 😀 The choice of quenching medium (air, oil, water, brine) affects the severity of quenching and the final hardness of the material, with water providing the highest hardness and brine providing the most severe quenching.

- 😀 The specific temperatures for heat treatment vary based on the type of material and the desired properties. For example, the temperature ranges differ for eutectoid, hypo-eutectoid, and hyper-eutectoid steels.

Q & A

What is heat treatment and why is it important?

-Heat treatment is a process where a material, usually a metal or its alloys, is heated and cooled under controlled conditions to alter its microstructure and properties. This is done to improve the material's mechanical, physical, and chemical properties, making it more suitable for specific applications.

What are the three main stages of heat treatment?

-The three main stages of heat treatment are: 1) Heating, where the material is brought to a specific temperature. 2) Holding, where the material is maintained at that temperature for a certain period of time. 3) Cooling, which can be done at different rates (slow, moderate, or fast).

How does heat treatment improve the material's properties?

-Heat treatment can improve mechanical properties (like strength and ductility), relieve residual stresses, enhance corrosion resistance, and modify physical and chemical properties to meet the requirements of different applications.

What is the purpose of annealing in heat treatment?

-Annealing is used to reduce the hardness of a material, making it more ductile and easier to work with. It also relieves internal stresses, improves machinability, and refines the material's microstructure.

What is the difference between annealing and normalizing?

-The key difference between annealing and normalizing is the cooling rate. Annealing involves slow cooling, often in a furnace, leading to a coarser grain structure. Normalizing, on the other hand, uses air cooling, which results in a finer grain structure and improved strength.

What happens during the hardening (quenching) process?

-During hardening, the material is heated to a specific temperature and then rapidly cooled, usually by immersing it in oil, water, or brine. This rapid cooling transforms the material's microstructure into a harder and stronger phase, typically martensite.

Why is tempering necessary after hardening?

-Tempering is performed after hardening to reduce the brittleness of the material and relieve the residual stresses induced during quenching. It also increases the material's toughness and ductility, ensuring dimensional stability.

What are the cooling methods used in quenching, and how do they affect the material?

-The cooling methods used in quenching include air, oil, water, and brine. Air cooling results in a softer material, while oil cooling produces moderate hardness. Water and brine provide the fastest cooling rates, resulting in the hardest material, with brine being the most severe.

What is the role of grain size in heat treatment?

-The grain size of a material plays a crucial role in its mechanical properties. Finer grains typically result in improved strength, while coarser grains provide higher ductility. Heat treatment processes like normalizing or annealing can control the grain size, influencing the material's final properties.

What is the difference between full annealing and partial annealing?

-Full annealing involves heating the material to a temperature above the critical point (usually between 1100-1200°C for steels) and then slowly cooling it in a furnace. Partial annealing, on the other hand, is performed at a lower temperature, often below the critical temperature, to achieve a desired microstructure without completely refining the grain.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade Now5.0 / 5 (0 votes)