Heat treatment of metals | Types. Process, Applications

Summary

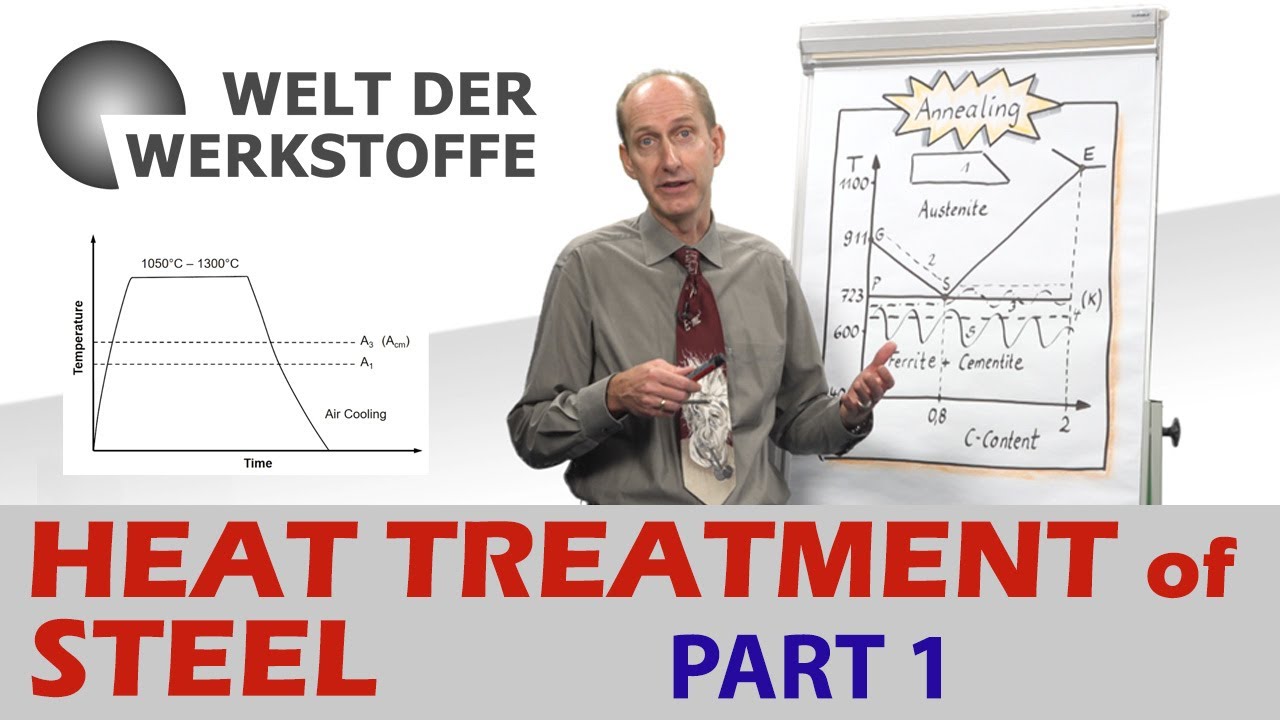

TLDRThis video explains the heat treatment of metals, including its types, processes, and applications. Heat treatment involves heating and cooling metals to enhance their mechanical properties, such as strength, ductility, and toughness. Key heat treatment methods covered include annealing, normalizing, hardening, tempering, and case hardening (which includes carburizing, cyaniding, nitriding, and flame hardening). The video also highlights the purpose and temperature ranges for each method and their impact on material properties. The applications of heat treatment in industries such as automotive, aerospace, and manufacturing are also discussed.

Takeaways

- 😀 Heat treatment is the process of heating and cooling metals to improve their mechanical properties.

- 😀 The main purposes of heat treatment include increasing strength, ductility, toughness, machinability, and relieving internal stresses.

- 😀 Heat treatment consists of three steps: heating the metal, holding it at the required temperature, and cooling it at a controlled rate.

- 😀 The five main types of heat treatments are annealing, normalizing, hardening, tempering, and case hardening.

- 😀 Annealing softens the material by heating it above its critical temperature, soaking it for 1-2 hours, and cooling it slowly.

- 😀 Normalizing is used to eliminate internal stresses and increase strength by heating the material slightly above its critical temperature and cooling it slowly.

- 😀 Hardening involves heating steel above its critical temperature, followed by rapid cooling (quenching) to increase hardness.

- 😀 Tempering is done after hardening to reduce internal stresses, restore ductility, toughness, and shock resistance.

- 😀 Case hardening involves hardening the surface of the material while keeping the core tough, using methods like carburizing, cyaniding, nitriding, and flame hardening.

- 😀 Applications of heat treatment are found in industries like automobile manufacturing, aerospace, hydraulics, and parts like shafts, gauges, and dyes.

Q & A

What is heat treatment of metals?

-Heat treatment is the process of heating and cooling metals under controlled conditions to achieve desired improvements in their mechanical properties, such as strength, toughness, and ductility.

What are the main purposes of heat treatment?

-Heat treatment is used to increase mechanical properties like ductility, strength, and toughness of metals. It is also used to enhance machinability, relieve internal stresses, and improve properties such as corrosion resistance and hardness.

What are the key steps in the heat treatment process?

-The heat treatment process involves three key steps: heating the metal to a specific temperature, soaking it at that temperature for a specific period, and then cooling it at a controlled rate to achieve the desired mechanical properties.

What are the different types of heat treatments?

-There are five main types of heat treatments: annealing, normalizing, hardening, tempering, and case hardening. Case hardening can be further done by carburizing, cyaniding, nitriding, and flame hardening.

What is annealing, and what is its purpose?

-Annealing is a heat treatment where material is heated above its critical temperature and then cooled slowly to relieve internal stresses, refine the grain structure, and increase ductility and toughness.

How does normalizing differ from annealing?

-Normalizing involves heating a material to 40-50°C above its critical temperature, soaking it for 15 minutes, and cooling it slowly. It is primarily used to eliminate internal stresses and increase strength, but it results in lower ductility compared to annealing.

What is the process of hardening?

-Hardening involves heating the metal above its critical temperature, soaking it at that temperature, and then rapidly cooling it (quenching) in oil, water, or polymer. This process increases hardness, but it can affect other mechanical properties like toughness and elasticity.

Why is tempering done after hardening?

-Tempering is done after hardening to relieve internal stresses caused by the rapid cooling in the hardening process. It also helps restore ductility, toughness, and shock resistance to the material.

What is case hardening, and how is it performed?

-Case hardening is a heat treatment process used to harden the surface of a material while maintaining a tough, ductile core. It can be done through various methods such as carburizing, cyaniding, nitriding, and flame hardening.

What are some common applications of heat treatment?

-Heat treatment is used in industries like automobiles, aerospace, and hydraulics. It is also applied in the manufacturing of parts like shafts, gauges, and dies, where mechanical properties such as wear resistance, strength, and toughness are critical.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

Properties and Grain Structure

Heat Treatment || Metallurgy || Materials Science

Heat Treatment - Types (Including Annealing), Process and Structures (Principles of Metallurgy)

Materiais e Processos de Fabricação para Engenharia de Produção - Materiais para Engenharia

Pitch sobre Curva de Escoamento

Material Science, Heat Treatment of Steel, Part 1

5.0 / 5 (0 votes)