Computer Numerical Control

Summary

TLDRThis video focuses on the fundamental principles of computer numerical control (CNC) for vertical Milling Machining Centers, highlighting their key features and axes of motion. The machine operates on three main linear axes: X, Y, and Z, with optional fourth rotary axis (A). The positioning system uses a rectangular coordinate system, where the X and Y axes are horizontal and vertical, respectively, while the Z-axis is perpendicular to both. It also covers the measurement increments used in different systems, explaining how coordinates define the cutting tool path on the machine, essential for precise machining operations.

Takeaways

- 😀 The script focuses on the basic computer numerical control (CNC) principles of a vertical Milling Machining Center.

- 😀 A vertical Milling Machining Center typically has three linear axes: X-axis, Y-axis, and Z-axis.

- 😀 The X-axis controls the side-to-side motion of the table.

- 😀 The Y-axis controls the in-and-out motion of the table.

- 😀 The Z-axis controls the up-and-down movement of the head column.

- 😀 A rotary table added to the machine introduces a fourth axis called the A-axis.

- 😀 Positioning along each axis is achieved using the rectangular coordinate system.

- 😀 In the rectangular coordinate system, the X-axis is represented by the horizontal baseline, and the Y-axis is represented by the vertical baseline.

- 😀 The Z-axis is perpendicular to both the X and Y axes.

- 😀 The smallest increment for machines using the English system is 1/1000th of an inch, while for metric machines, it is usually 1/1000th of a millimeter.

- 😀 The tool path in CNC machining refers to the specific coordinates where the cutting tool is instructed to move.

Q & A

What is the primary focus of the program mentioned in the script?

-The program focuses primarily on the basic computer numerical control (CNC) principles of a vertical Milling Machining Center.

What are the three linear axes of motion in a vertical Milling Machining Center?

-The three linear axes of motion are the X-axis (side to side motion), Y-axis (in and out motion), and Z-axis (up and down movement of the head).

What does the 'A-axis' refer to in the context of a vertical Milling Machining Center?

-The A-axis refers to a fourth rotary axis, which is added when a rotary table is included on the machine table.

How is accurate positioning achieved along each axis in a vertical Milling Machining Center?

-Accurate positioning is achieved using the rectangular coordinate system.

How does the rectangular coordinate system work in the context of a vertical Milling Machining Center?

-In the rectangular coordinate system, the X-axis is represented by the horizontal baseline, and the Y-axis is represented by the vertical baseline. The Z-axis is perpendicular to both the X and Y axes.

What unit of measurement is typically used for increments in the coordinate system?

-For most machines, the smallest increment is 1/1000 of an inch (in the English system), or 1/1000th of a millimeter (in the metric system).

What does the rectangular coordinate system allow in terms of machine movement?

-The rectangular coordinate system allows for the mathematical plotting of points in space, which correspond to coordinates among two or more machine axes.

What is the significance of coordinates in CNC machining?

-Coordinates indicate the physical location where the machine's cutting tool is instructed to move, and they collectively define the tool path.

What does the 'tool path' refer to in the context of CNC machining?

-The tool path refers to the collective series of coordinates that define the precise movement of the cutting tool during machining.

Why is the rectangular coordinate system important in CNC machining?

-The rectangular coordinate system is essential for ensuring precise machine movements, accurate positioning, and the correct execution of the tool path in CNC machining.

Outlines

Cette section est réservée aux utilisateurs payants. Améliorez votre compte pour accéder à cette section.

Améliorer maintenantMindmap

Cette section est réservée aux utilisateurs payants. Améliorez votre compte pour accéder à cette section.

Améliorer maintenantKeywords

Cette section est réservée aux utilisateurs payants. Améliorez votre compte pour accéder à cette section.

Améliorer maintenantHighlights

Cette section est réservée aux utilisateurs payants. Améliorez votre compte pour accéder à cette section.

Améliorer maintenantTranscripts

Cette section est réservée aux utilisateurs payants. Améliorez votre compte pour accéder à cette section.

Améliorer maintenantVoir Plus de Vidéos Connexes

HEAVY DUTY LATHES. Most Mesmerizing Collection of CNC Machine Processes.

Milling machine tutorial - cutter selection, speeds and feeds, coolant, high speed machining

INTRODUCTION TO CNC MILL PROGRAMMING

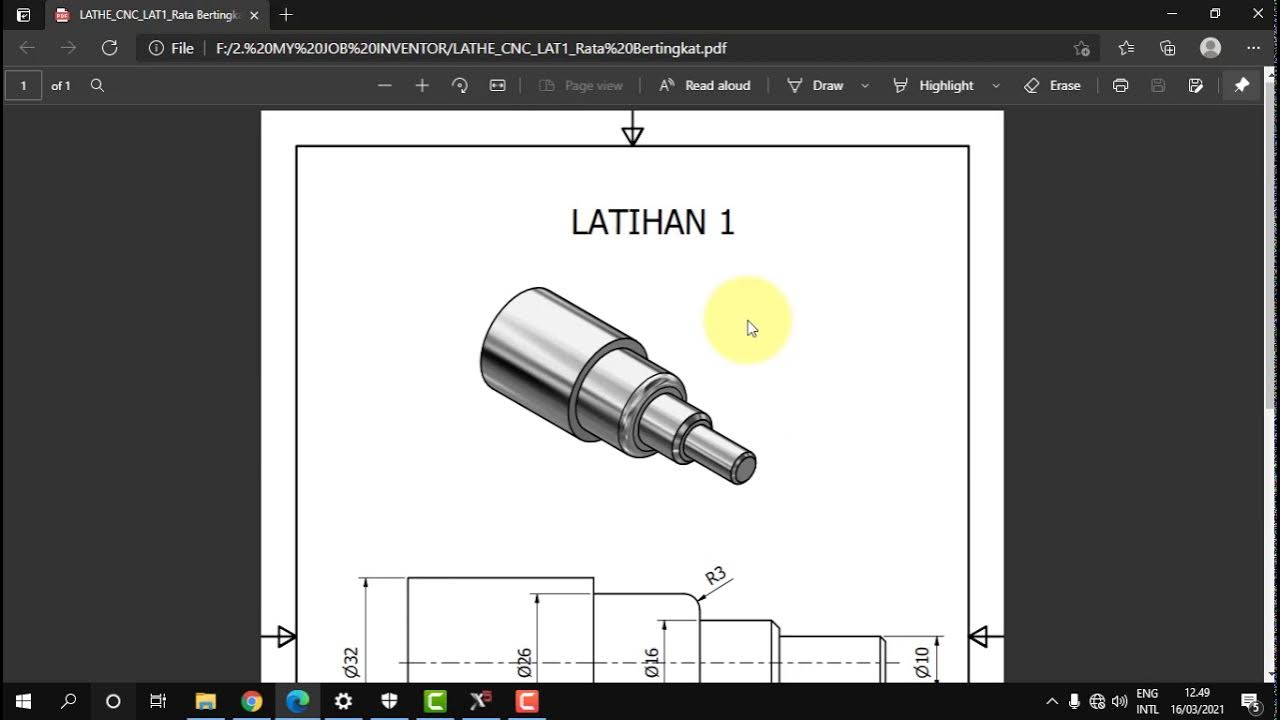

membuat program sederhana CNC Milling

CNC Lathe Basics: How CNC Lathe Turning Works

MASTERCAM X5_BUBUT DASAR BIDANG BERTINGKAT

5.0 / 5 (0 votes)