HEAVY DUTY LATHES. Most Mesmerizing Collection of CNC Machine Processes.

Summary

TLDRThis video showcases the intricate world of CNC machining, highlighting the challenges and techniques involved in machining large workpieces with high precision. It delves into the importance of machine capacity, structural integrity, thermal stability, and tooling. The video also explores various machining processes like roughing cycles, square keyway milling, vertical milling, and thread cutting, emphasizing the role of specialized equipment and the expertise required in industries such as aerospace and heavy machinery. Additionally, it covers the advantages and disadvantages of brass material machining and introduces innovative techniques like trocoidal milling and high-performance end mills, showcasing the latest in CNC technology.

Takeaways

- 😲 Large-scale CNC machining requires specialized equipment and expertise to achieve high precision and accuracy with heavy and large workpieces.

- 💪 Machine capacity is crucial for handling the substantial weight and size of large workpieces, necessitating powerful and robust machinery.

- 🏗️ Structural integrity is vital in CNC machining to counteract vibrations and maintain dimensional accuracy, often requiring reinforced structures and damping systems.

- 🔥 Thermal stability is essential to manage the expansion of large workpieces during machining, which can affect precision.

- 🛠️ Tooling and fixturing for large workpieces is complex and must securely hold the workpiece for multiple machining operations without loss of precision.

- ⚙️ Selecting appropriate cutting parameters is key to preventing tool wear, ensuring consistent material removal, and maintaining surface finish.

- 🚜 Logistics and handling of extremely large workpieces require careful planning and specialized equipment like cranes and custom transport solutions.

- 🔩 Thread cutting from the center is a precise technique used to create internal threads, crucial for secure connections in components like nuts and bolts.

- 🔨 High-performance CNC machines, like the Waldrich Plano Miller, use powerful motors and specialized cutters to shape large plates made of high-strength alloys.

- 🌟 Brass material machining by CNC offers advantages like excellent machinability, dimensional accuracy, and a wide range of applications, but also has disadvantages like higher material cost and potential tool wear.

- 🔧 Advanced machining techniques and equipment, such as trocoidal milling and high-speed machining with end mills like Goring's RF-100, improve metal removal rates and productivity.

Q & A

What is the main focus of the video?

-The video focuses on exploring various CNC machining processes, emphasizing the challenges and techniques involved in machining large workpieces with high precision and accuracy.

What is the 'double shooting' technique mentioned in the script?

-The 'double shooting' technique is a specialized method used by Simple Camp, a renowned company in the field, for high precision machining of very large and heavy workpieces.

What are some of the key challenges associated with machining large workpieces?

-Key challenges include machine capacity, structural integrity, thermal stability, tooling and fixturing, cutting parameters, logistics and handling, and chip management.

Why is maintaining structural integrity crucial during large workpiece machining?

-Structural integrity is crucial to prevent vibrations induced by cutting forces, which can lead to deflection and affect the dimensional accuracy of the finished product.

How does thermal stability impact the machining of large workpieces?

-Thermal stability is important as large workpieces are prone to thermal expansion during machining, which can introduce dimensional inaccuracies. Managing heat generation and dissipation is crucial for maintaining the workpiece's stability and ensuring precise machining.

What is the significance of selecting appropriate cutting parameters in CNC machining?

-Appropriate cutting parameters are vital to prevent tool wear, ensure consistent material removal rates, and maintain surface finish. Achieving the right balance between cutting speed, feed rate, and depth of cut is essential for efficient and precise machining.

What is the roughing cycle in CNC machining?

-The roughing cycle is the initial stage of material removal where the cutting tool rapidly eliminates excess material from the workpiece. It aims to reduce the overall stock material efficiently, preparing the workpiece for subsequent finishing operations.

What is the purpose of square keyway milling?

-Square keyway milling is a milling operation focused on creating a square-shaped groove or keyway within a workpiece. Keyways are essential for components like shafts and gears that require a positive connection with mating parts such as pulleys or gears.

What are the advantages of brass material machining by CNC machine?

-Advantages include excellent machinability, dimensional accuracy, a wide range of applications, naturally attractive appearance with a golden hue, and corrosion resistance. Brass is softer and more ductile than many other metals, leading to smoother and faster machining operations.

What is the significance of the goring's rf-100 end mills in high-speed machining?

-Goring's rf-100 end mills are known for their exceptional performance and almost endless tool life. They are manufactured with a focus on quality control over the raw material, leading to longer and highly repeatable tool life, which is crucial for high-speed machining operations.

What is the role of the CNC slant bed turning center lathe in precision turning operations?

-The CNC slant bed turning center lathe is designed for precision turning operations. Its slanted bed design enhances chip flow, improves rigidity, and promotes better operator access to the workpiece, resulting in increased productivity and accuracy.

What are the key features of the Dugard heavy duty vertical machining center 2210b?

-Key features include a spacious working envelope, a potent motor, a bi-directional twin arm type auto tool changer with a 24 station capacity, and optional upgrades such as a direct drive spindle with a refrigeration unit and a 32 tool ATC system for enhanced machining capabilities.

What is the importance of helical interpolation in various industries?

-Helical interpolation is crucial for creating complex, precise, and smooth curves in industries such as Aerospace, automotive, and manufacturing, where such curves are essential for the production of high-quality components.

What are the benefits of the Heller five-axis milling turning center cp6000?

-The cp6000 offers a universal 5-axis setup, simultaneous 5-axis machining, and five-sided machining with positioned rotary axes. It is suitable for a wide range of parts and materials, making it highly adaptable to diverse manufacturing requirements.

What is the role of the amugi search GF indexable thread mill in thread milling operations?

-The amugi search GF indexable thread mill is designed to deliver maximum confidence, depth, versatility, and cost-effectiveness in thread milling operations. It allows users to produce threads with impeccable form, finish, and dimensional accuracy, and simplifies the machining of challenging materials.

What are the advantages of Heller's crankshaft production systems?

-Heller's crankshaft production systems offer customizability, high productivity due to advanced machining technologies, and the ability to handle complex tasks such as simultaneous machining of main bearings and crank pin journal profiles in a single setup.

What are the key features of the Haas ST-20Y axis CNC turning center?

-The Haas ST-20Y features a y-axis capability for off-center milling, drilling, and tapping, high torque live tooling, a servo-driven C-axis for four-axis capability, and a compact and rigid design for increased stability and cutting performance.

What is the significance of the Haas ST-10Y CNC lathe in the manufacturing industry?

-The Haas ST-10Y is a compact yet powerful CNC lathe designed for excellent performance with minimal floor space. It offers a generous workspace for various turning operations and is equipped with high torque live tooling and a servo-driven C-axis, making it an ideal choice for startups or as an entry into CNC turning.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

5 Axis CNC Machining For Your Parts | WayKen Rapid Manufacturing

CNC Basics - Everything a Beginner Needs To Know

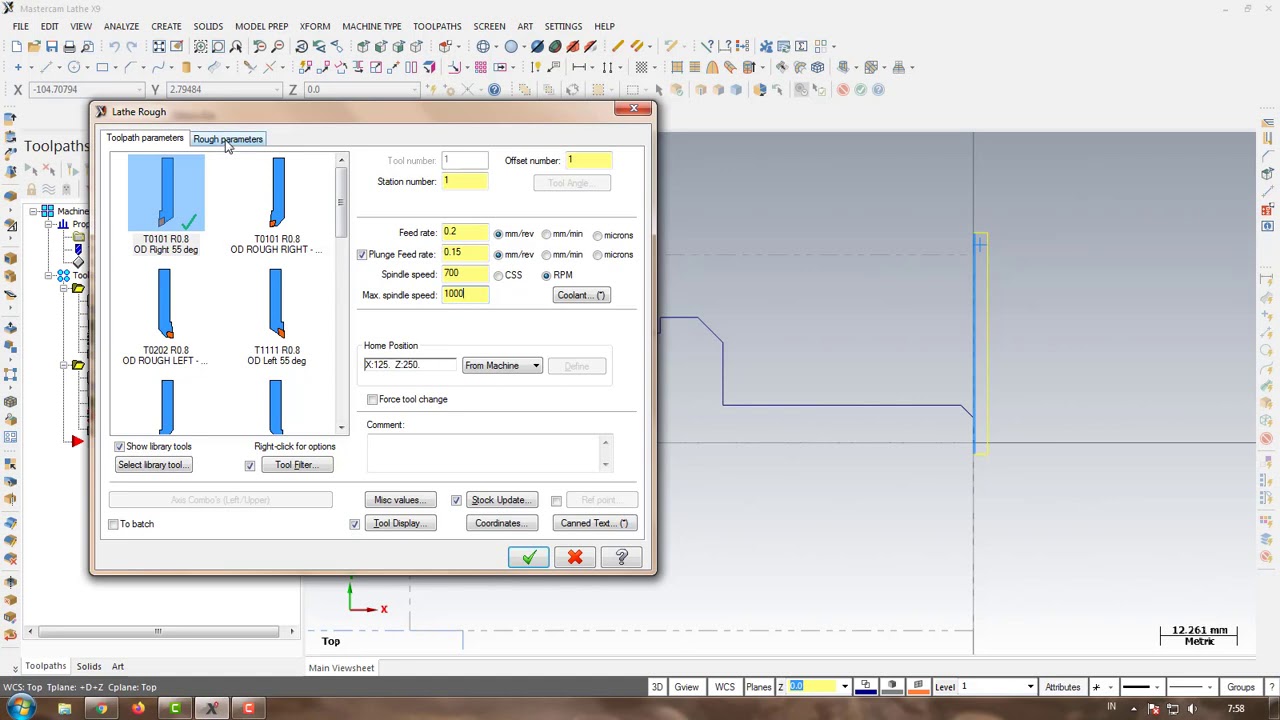

Program CNC Turning Menggunakan MasterCAM X9 (Pembuatan PIN)

CNC Lathe Basics: How CNC Lathe Turning Works

Materiais e Processos de Fabricação para Engenharia de Produção: Usinagem não convencional

Proses Pemesinan Non Tradisional part 1

5.0 / 5 (0 votes)