INTRODUCTION TO CNC MILL PROGRAMMING

Summary

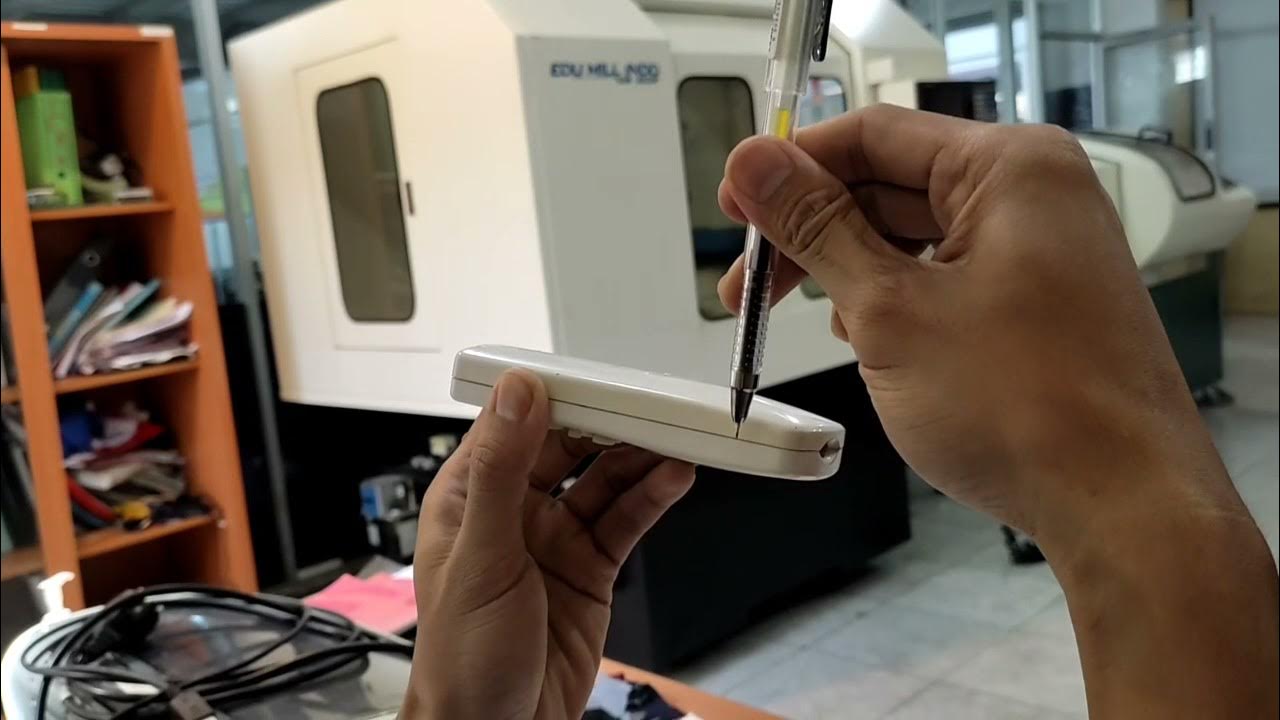

TLDRThis instructional video script introduces the basics of CNC programming for a CNC mill, focusing on the Cartesian coordinate system's relevance to CNC. It explains the concept of positive and negative values in the X and Y axes, the significance of the origin, and how these values change with different quadrants. The script also touches on the Z-axis, crucial for depth in milling operations. It aims to demystify CNC programming by illustrating how machines understand coordinates to perform tasks like drilling holes in a block, emphasizing the importance of establishing the origin for accurate machining.

Takeaways

- 📚 The video script is an educational resource on basic CNC programming for CNC mills.

- 📐 It introduces the Cartesian coordinate system as it relates to CNC programming, focusing on the X and Y axes.

- 📍 The origin is defined as the intersection of the X and Y axes, where both have a value of zero.

- ➕ Understanding the positive (+) and negative (-) values of coordinates is crucial for CNC programming.

- 🔄 The script explains how moving in different directions from the origin results in different X and Y values.

- 🔺 Points in different quadrants have specific combinations of positive and negative X and Y values.

- 📈 The script uses an 8x8 square grid to illustrate how the position of the origin affects the coordinates of points.

- 🔄 It also demonstrates how shifting the grid to a different quadrant changes the X and Y values of the points.

- 🔱 The Z-axis is introduced as the third plane, adding depth to the two-dimensional X and Y plane.

- 🔩 The importance of determining the origin's location when setting up a part in the machine is emphasized.

- 🛠 The script concludes by setting the stage for the next video, which will discuss selecting coordinates for tool paths in milling.

Q & A

What is the purpose of the video series on CNC programming for the CNC mill?

-The purpose of the video series is to explain the basics of CNC programming, including the meaning of the coordinates (X, Y, Z), the G and M codes, and how to understand and create CNC programs.

What is the Cartesian coordinate system and how does it relate to CNC programming?

-The Cartesian coordinate system is a mathematical model used to define positions on a plane or in three-dimensional space. In CNC programming, it is used to determine the position of the tool relative to the part being machined, using X, Y, and Z axes.

What is the significance of positive and negative values in the Cartesian coordinate system as it pertains to CNC programming?

-Positive and negative values in the Cartesian coordinate system are crucial in CNC programming as they indicate the direction of movement along the X, Y, and Z axes. They help the CNC machine to know whether to move in a positive (right, up, or away from the origin) or negative (left, down, or towards the origin) direction.

How is the origin defined in the context of the video script?

-In the context of the video script, the origin is defined as the point where the X and Y axes intersect, with both X and Y values being zero. The origin serves as the reference point for all other coordinates in the CNC program.

What are the four quadrants of the Cartesian coordinate system and how do they affect the sign of the coordinates?

-The four quadrants of the Cartesian coordinate system are numbered I to IV. In quadrant I, both X and Y have positive values. In quadrant II, X is negative, and Y is positive. In quadrant III, both X and Y are negative. In quadrant IV, X is positive, and Y is negative. The quadrant in which a point lies determines the sign of its coordinates.

Why is it important to understand the placement of the origin in a CNC program?

-Understanding the placement of the origin is important because it determines the X and Y values and their signs. The origin's position affects how the CNC machine interprets the coordinates for tool movement, which in turn affects the machining process.

What is the Z axis in the context of a three-axis CNC mill, and how does it differ from the X and Y axes?

-The Z axis represents the height or depth in a three-axis CNC mill. It differs from the X and Y axes, which represent the horizontal and vertical positions on a plane, respectively. The Z axis allows the CNC machine to move the tool up and down, adding depth to the machining process.

How does the CNC machine interpret the movement of the tool in the Z axis?

-The CNC machine interprets movement in the Z axis as the tool moving towards or away from the workpiece. A positive Z value indicates the tool moving away from the workpiece, while a negative Z value indicates the tool moving towards the workpiece.

What is the significance of the Z axis in relation to the machining process?

-The Z axis is significant in the machining process as it allows for the creation of three-dimensional shapes. It controls the depth of cuts, the height of the workpiece, and the movement of the tool in the vertical direction.

How does the video script illustrate the importance of understanding the Cartesian coordinate system for CNC programming?

-The video script illustrates this by showing how the placement of the origin and the understanding of the quadrants affect the coordinates used in a CNC program. It uses an example of drilling holes in a block, demonstrating how the coordinates change based on the origin's location and the direction of the tool movement.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

Dasar Pemrograman Mesin CNC TU 2A (Absolut dan Inkremental)

CNC Basics - Everything a Beginner Needs To Know

Turning operation in CREO manufacturing with generating NC part programme

membuat program sederhana CNC Milling

Cara Setting Titik Nol Benda Kerja CNC Milling

CNC Lathe Basics: How CNC Lathe Turning Works

5.0 / 5 (0 votes)