Sistem Pneumatik

Summary

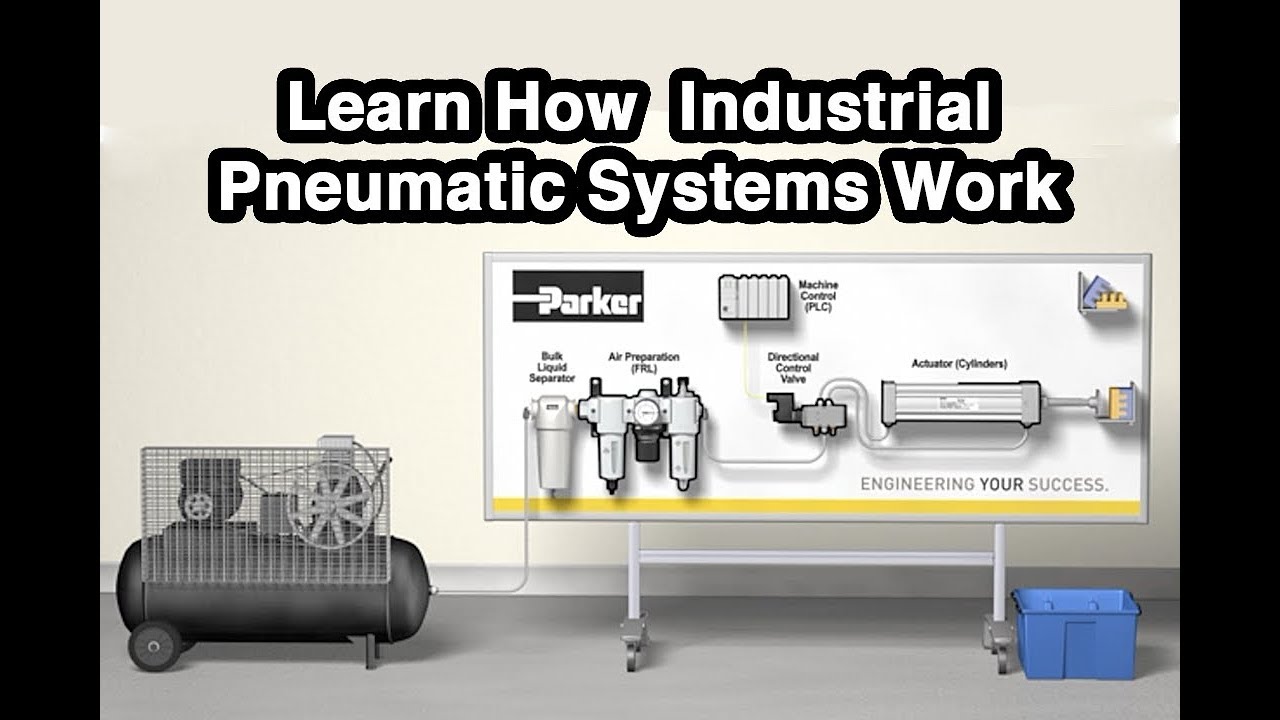

TLDRThis video explains the working of a pneumatic system, which utilizes compressed air to perform various industrial tasks. It covers the key components such as compressors, liquid separators, filters, regulators, lubricators, directional control valves, and actuators. The system is designed to move products, apply force, and assemble components efficiently. The air is carefully processed to ensure dryness and cleanliness, while the pressure is regulated for precise motion. Control valves and actuators allow for accurate direction and movement, making the system essential for automation in industries requiring consistent and reliable force generation.

Takeaways

- 😀 The pneumatic system introduced is supplied by Parker and is widely used in various industries for tasks such as moving products or applying force to components.

- 😀 The system begins with a compressor that draws in atmospheric air, compresses it, and directs it into the pneumatic system.

- 😀 The air is then conditioned through a series of components: a liquid separator or dryer to ensure dry air, a filter to remove dust, and a regulator to control the air pressure.

- 😀 The regulator allows precise control of the air pressure entering the system, using a spring mechanism and valve to adjust it.

- 😀 A lubricator is included in the system to add lubrication to the air, which helps reduce friction in moving parts like pistons.

- 😀 Directional control valves regulate the flow of air into actuators, controlling their movement and ensuring precise direction control.

- 😀 The system uses a PLC (Programmable Logic Controller) to manage the movement of the directional control valve and actuator based on the desired flow of air.

- 😀 Actuators convert the pressurized air into mechanical motion, either linear or rotary, to perform tasks such as pressing components into place.

- 😀 The pneumatic system is designed to expel waste air after completing a task, ensuring that no excess air remains in the system.

- 😀 The system's components work in harmony to automate industrial processes, improving efficiency in applications like assembly lines and machinery maintenance.

Q & A

What is the main purpose of the pneumatic system described in the transcript?

-The primary purpose of the pneumatic system is to generate movement, which is widely used in industries for various tasks, such as transferring products from one place to another and applying force to assemble components.

How does the air compressor function in the pneumatic system?

-The air compressor sucks in atmospheric air, compresses it to a certain pressure, and then sends the compressed air through pipes or hoses into the pneumatic system.

What is the role of the liquid separator in the pneumatic system?

-The liquid separator separates liquid from the air by using centrifugal force, ensuring that only dry air flows into the system, preventing water from entering and affecting the system's components.

What does the efferail system consist of, and what is its function?

-The efferail system consists of a filter, a regulator, and a lubricator. The filter removes dust and debris from the air, the regulator controls the air pressure entering the system, and the lubricator adds oil to the air to reduce friction in moving parts.

How does the regulator work in the pneumatic system?

-The regulator adjusts the air pressure entering the system by using a spring and a valve. When the knob is turned, it adjusts the spring, which opens the valve and regulates the airflow, ensuring the desired pressure.

What is the function of a lubricator in the pneumatic system?

-The lubricator adds oil to the compressed air, which helps reduce friction in parts like pistons and moving components, improving their performance and longevity.

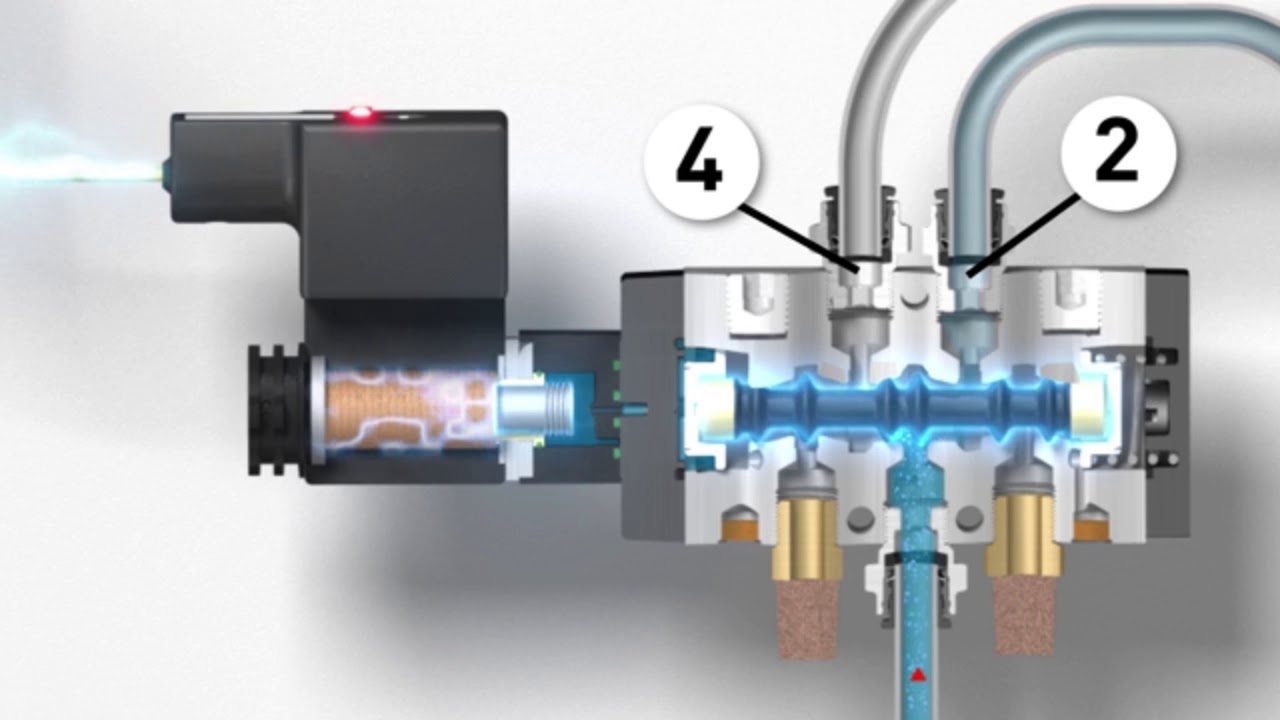

How does the directional control valve (DCV) function in controlling airflow?

-The DCV controls the direction of air flow by opening or closing specific ports, directing compressed air to move actuators in either direction. It is typically controlled by a PLC (Programmable Logic Controller), which sends electrical signals to adjust the valve's position.

What is the role of a PLC in controlling the directional control valve?

-A PLC provides electrical signals to the directional control valve, generating a magnetic field that causes the valve to move, thereby controlling the airflow direction to the actuator.

How does an actuator work in the pneumatic system?

-An actuator converts the airflow into mechanical motion, which can either be a linear or rotary movement. The actuator’s movement is controlled by the pressurized air flowing through the directional control valve.

What happens when the actuator's direction needs to be reversed?

-To reverse the actuator's direction, the airflow is redirected through the opposite port in the directional control valve. The exhaust air is then released from the actuator, allowing the actuator to move in the opposite direction.

Outlines

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraMindmap

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraKeywords

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraHighlights

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraTranscripts

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraVer Más Videos Relacionados

How a Industrial Pneumatic Systems Works And The Five Most Common Elements Used

Neumática Industrial, ¿Cómo Trabaja un Sistema Neumático?

Basics of Pneumatics and Pneumatic Systems: Part 1 (Animation / Sub)

Top 12 Pneumatic Projects | Air Powered Pneumatic Systems for Industrial & Robotics

Pneumatic Cylinder: How Does It Work?

Dasar - dasar Otomotif BAB 10 Part 1 SISTEM HIDROLIK DAN PNEUMATIK PADA OTOMOTIF

5.0 / 5 (0 votes)