Basics of Pneumatics and Pneumatic Systems: Part 1 (Animation / Sub)

Summary

TLDRIn this educational video, Miss Pneumatic introduces the basics of pneumatics, explaining how compressed air is used to perform work. The video covers the essential components of a pneumatic system, including air compression, air quality control, and the role of filtration and lubrication. Through a simple example involving a balloon, viewers learn how compressed air is stored, filtered, and regulated for optimal performance. The speaker emphasizes the importance of maintaining clean air to ensure system efficiency and longevity. Future videos will delve deeper into air control and actuator components for a comprehensive understanding of pneumatic systems.

Takeaways

- 😀 Pneumatics is the science and technology of performing work using compressed air.

- 😀 Compressed air can be used to move mechanical components and operate machinery.

- 😀 The basic principle of pneumatics is converting potential energy from compressed air into kinetic energy, as shown by the example of a balloon.

- 😀 An air compressor intakes and compresses air from the surroundings, similar to how your nose and mouth work in inflating a balloon.

- 😀 After compression, the air is stored in an air tank, which is similar to the way a balloon holds compressed air.

- 😀 Impurities like moisture, oil, and dust are removed from the air before it is used in the pneumatic system, ensuring efficiency.

- 😀 Air goes through quality control segments where it's filtered, its pressure is adjusted, and lubrication is added to maintain actuator functionality.

- 😀 A regulator reduces and maintains the pressure of compressed air, ensuring consistent output.

- 😀 A lubricator injects lubricant into the compressed air to ensure smooth operation of the actuator, though its use is optional.

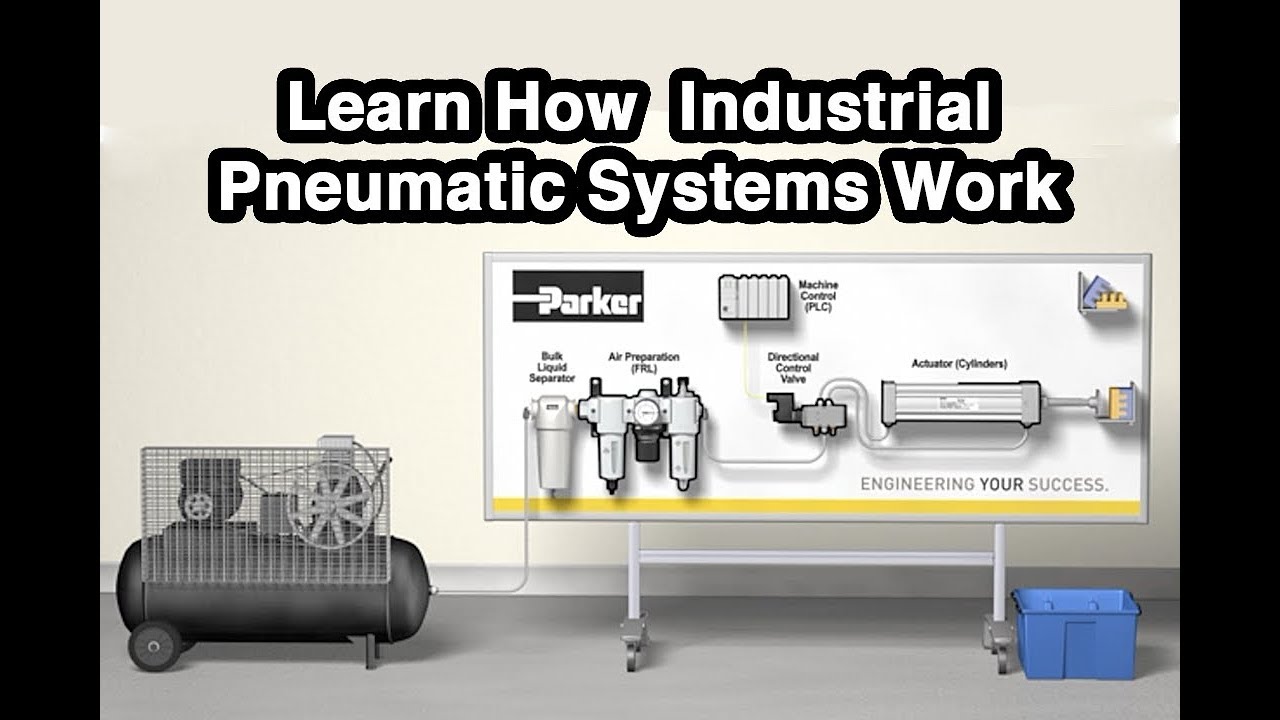

- 😀 The pneumatic system has several segments: air compression, air quality control, air control, and actuator segments, each playing a crucial role in the system's operation.

Q & A

What is pneumatics?

-Pneumatics refers to the science and technology of performing work using machinery powered by compressed air. It involves using compressed air to move mechanical components and operate machinery.

How does a balloon illustrate the basic principles of pneumatics?

-When air is blown into a balloon, the air becomes compressed, storing potential energy. When released, the air escapes, converting the stored potential energy into kinetic energy, causing the balloon to move. This basic principle mirrors how pneumatic systems work with compressed air.

What is the role of an air compressor in a pneumatic system?

-The air compressor intakes air from the surroundings and compresses it, similar to how the nose and mouth work in the balloon example. It provides the pressurized air needed to move mechanical components in a pneumatic system.

What happens to the compressed air once it leaves the compressor?

-After the compressor compresses the air, it is stored in an air tank. The air then goes through various processes like cooling, drying, filtering, and regulating to ensure it is clean and at the proper pressure before reaching the actuator.

Why is moisture removed from the compressed air?

-Moisture is removed because it can create issues such as rust or corrosion in the system, and it can also reduce the efficiency and lifespan of the machinery. After the air is compressed, moisture is removed using an after cooler and air dryer.

What is the purpose of air quality control in a pneumatic system?

-The air quality control segment filters impurities such as oil, dust, and residual moisture from the compressed air. It also adjusts air pressure and adds lubricant to ensure that the actuator operates smoothly and efficiently.

How does an air filter contribute to the system's performance?

-An air filter removes impurities like oil, dust, and moisture that were not eliminated earlier in the process. By continuously filtering the air, it enhances the mechanical efficiency of the actuator and prolongs the lifespan of the components.

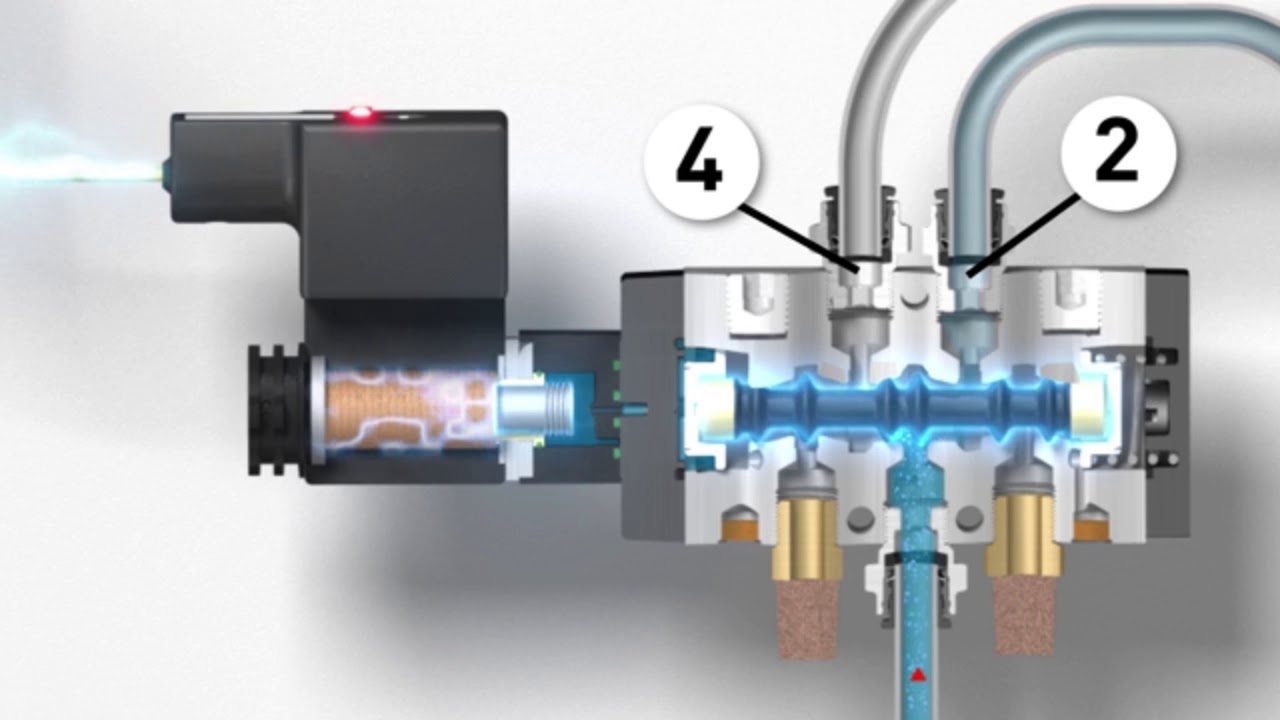

What does a regulator do in a pneumatic system?

-A regulator reduces the air pressure to a desired level and maintains a constant output pressure. This ensures that the pneumatic components receive air at the correct pressure, optimizing their performance.

What is the role of a lubricator in a pneumatic system?

-A lubricator injects lubricant into the air flowing through the system to ensure the actuator works smoothly. It helps to reduce wear and tear, boosting the durability of the components. However, it is optional and may not be used in all systems.

What will be covered in the next part of the video?

-In the next part of the video, the focus will shift to the air control segment, where the direction and volume of airflow are controlled. The video will also cover the actuator segment, showcasing the actual system components.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

How a Industrial Pneumatic Systems Works And The Five Most Common Elements Used

Neumática Industrial, ¿Cómo Trabaja un Sistema Neumático?

Dasar sistem pneumatic

Directional Control Valve Working Animation | 5/2 Solenoid Valve | Pneumatic Valve Symbols Explained

BAGIAN-BAGIAN SYSTEM PNEUMATIC

RC Drilling Introduction

5.0 / 5 (0 votes)