Pneumatic Cylinder: How Does It Work?

Summary

TLDRA pneumatic cylinder transforms compressed air into linear motion. Compressed air enters the cylinder, pushing the piston inside a barrel. In single-acting cylinders, air affects the piston on one side, with spring or load reversing the motion. Double-acting cylinders use air pressure on both sides for extension and retraction. The system requires precise sealing for airtightness, and a directional valve controls air flow, dictating the piston's movement. This overview of pneumatic systems highlights the components and mechanism that ensure smooth and efficient operation.

Takeaways

- 🔧 A pneumatic cylinder converts compressed air energy into linear motion.

- 💨 Compressed air enters the cylinder, pressing on the piston inside the barrel.

- 📏 The piston moves under pressure, causing the attached rod to move with it, lifting loads or moving mechanisms.

- ⚙️ In single-acting cylinders, air affects the piston from one side, and the reverse motion is due to spring force or load.

- 🔁 In double-acting cylinders, air affects the piston from both sides, allowing the rod to extend and retract by controlling air flow.

- 🔍 The cylinder piston is inside a smooth-surfaced barrel with seals separating the piston and rod cavities.

- 🧲 Magnet rings allow sensors to determine the piston's position inside the cylinder.

- 🚪 Front and end caps, with O-ring seals, ensure the pneumatic cylinder remains airtight.

- 🔄 A pneumatic directional valve controls the movement of compressed air into the cylinder, enabling extension and retraction of the rod.

- 🔩 Surfaces in contact with the seals must be smooth to avoid damage and ensure proper sealing.

Q & A

What is the main function of a pneumatic cylinder?

-A pneumatic cylinder converts compressed air energy into linear motion, allowing for mechanical tasks such as lifting loads or moving mechanisms.

How does compressed air move the piston in a pneumatic cylinder?

-Compressed air enters the cylinder cavity through the cap, pressing on the piston in the cylinder barrel. This pressure moves the piston, which in turn moves the attached rod.

What is the difference between a single-acting and a double-acting pneumatic cylinder?

-In a single-acting pneumatic cylinder, compressed air affects the piston from only one side, with the reverse motion occurring through spring force or load. In a double-acting cylinder, air affects the piston from both sides, allowing more control over extension and retraction.

How does a double-acting pneumatic cylinder extend and retract its rod?

-To extend the rod, compressed air is introduced into the piston cavity while air from the rod cavity is sent to the atmosphere. To retract the rod, compressed air is introduced into the rod cavity while air from the piston cavity is released to the atmosphere.

What components are found inside a pneumatic cylinder?

-A pneumatic cylinder contains a cylinder piston, cylinder barrel, seals, guide rings, magnet rings, a long rod, O-ring seals, front and end caps, and a wiper seal.

What role do seals and guide rings play in a pneumatic cylinder?

-Seals separate the piston and rod cavities to ensure airtightness, while guide rings help the piston slide smoothly along the cylinder barrel.

Why is a smooth surface important for the rod and cylinder barrel?

-A smooth surface is essential to prevent damage to the seals and ensure a close, airtight contact between the seals and the surfaces, facilitating efficient operation.

How is the position of the piston determined in a pneumatic cylinder?

-Magnet rings are used within the cylinder to allow sensors to detect the piston’s position.

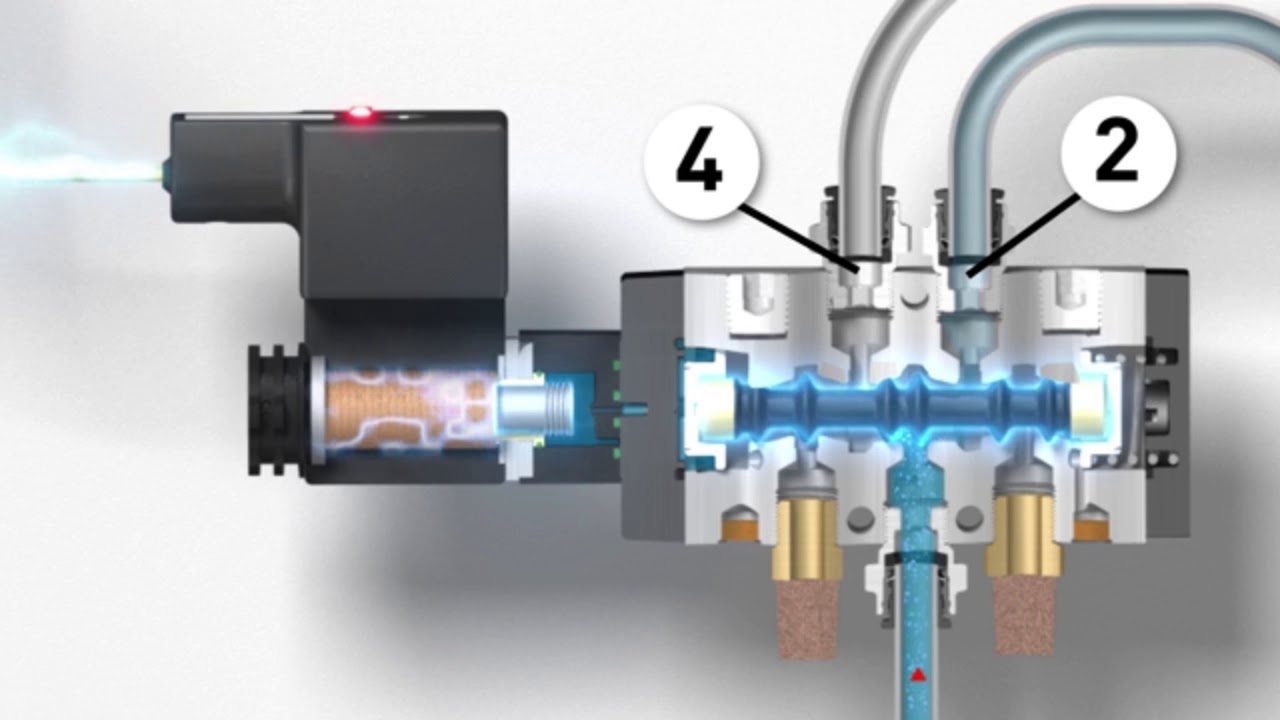

What does the pneumatic directional valve do in the system?

-The pneumatic directional valve controls the movement of air to and from the piston and rod cavities, allowing for precise control of the cylinder's motion.

How does the overall pneumatic system operate?

-The pneumatic system operates by moving compressed air from a compressor to the valve. When the valve is switched, air moves to the piston cavity or rod cavity, enabling the rod to extend or retract, depending on the valve position.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

Pneumatic Cylinder Working explained (Animation)

How a Industrial Pneumatic Systems Works And The Five Most Common Elements Used

Basics of Pneumatics and Pneumatic Systems: Part 1 (Animation / Sub)

Neumática Industrial, ¿Cómo Trabaja un Sistema Neumático?

Directional Control Valve Working Animation | 5/2 Solenoid Valve | Pneumatic Valve Symbols Explained

Poisoning AI with ".аss" subtitles

5.0 / 5 (0 votes)