Neumática Industrial, ¿Cómo Trabaja un Sistema Neumático?

Summary

TLDRThis video provides an in-depth overview of how industrial pneumatic systems operate. It covers the essential components, such as the compressor, air preparation unit, and directional control valves, explaining their functions in generating and directing compressed air to create motion. The system includes air filtration, regulation, lubrication, and the use of actuators to perform tasks in industrial automation, such as moving and assembling products. By utilizing clean, dry air and precise pressure control, pneumatic systems enable efficient, automated processes in manufacturing environments.

Takeaways

- 😀 Pneumatic systems in industrial applications primarily focus on creating motion to perform tasks in environments such as moving products or pressing/sorting parts.

- 😀 The compressor is the core component that generates compressed air, which powers the system by creating the necessary energy for controlling it.

- 😀 Compressed air must be dry and clean to prevent contaminants like rust and dirt from damaging the system's moving parts.

- 😀 The air preparation unit includes a separator that removes moisture, a filter that eliminates particles, and a regulator that controls air pressure.

- 😀 The regulator adjusts the air pressure, affecting the force generated in the system; higher pressure results in more force, while lower pressure generates less.

- 😀 A manometer or gauge on the regulator allows users to monitor the system's pressure to ensure it remains within the desired range.

- 😀 A directional control valve is responsible for directing the airflow to the necessary areas to create movement in the system.

- 😀 The operation of the directional valve is controlled by a PLC (Programmable Logic Controller) that sends an electrical signal to switch the valve's direction using an electromagnet and a spool.

- 😀 The actuator is responsible for converting compressed air into mechanical motion, allowing movement in various directions based on the system's needs.

- 😀 Pneumatic systems are commonly used in industrial automation to handle repetitive tasks, such as moving parts in assembly lines or securing components in place.

- 😀 The entire system can be adjusted and controlled by the PLC, which ensures that the actuator moves items from one point to another, repeating the process as needed.

Q & A

What is the primary purpose of an industrial pneumatic system?

-The primary purpose of an industrial pneumatic system is to create motion that performs some form of work, such as moving products, pressing, or holding parts in an industrial setting.

How does a compressor function in a pneumatic system?

-A compressor generates the energy required to power the pneumatic system by compressing air from the environment, which is then used to create the necessary pressure for the system to function.

Why is it important to ensure that compressed air is dry and clean in a pneumatic system?

-Compressed air needs to be dry and clean to prevent harmful particles, such as rust or dirt, from obstructing the system's moving parts, which could lead to failure or inefficiency.

What is the role of the air preparation unit in the pneumatic system?

-The air preparation unit, which includes a filter, regulator, and lubricator (FRL), cleans, regulates the pressure, and lubricates the compressed air to ensure smooth operation of the system.

What function does the separator in the air preparation unit serve?

-The separator in the air preparation unit uses centrifugal force to eliminate unwanted moisture from the compressed air, ensuring the air remains dry.

How does a pressure regulator control the force generated by the pneumatic system?

-A pressure regulator adjusts the pressure of the compressed air, which in turn controls the force generated by the actuators. Higher pressure results in greater force, while lower pressure generates less force.

How does a directional control valve work in a pneumatic system?

-A directional control valve directs the flow of compressed air to different parts of the system, controlling the movement of actuators. It achieves this by using internal elements called spools that switch the airflow between ports.

What is the purpose of the actuator in the pneumatic system?

-The actuator converts the compressed air's energy into mechanical movement, enabling tasks such as pushing, pulling, or moving components in an industrial process.

What happens when the PLC (Programmable Logic Controller) sends a signal to the directional control valve?

-When the PLC sends a signal to the directional control valve, it activates an electromagnet (solenoid) that moves the valve's spool, changing the direction of the compressed air flow to control actuator movement.

What occurs when the actuator reaches its physical limit or encounters resistance?

-When the actuator reaches its physical limit or encounters resistance greater than the force from the compressed air, the system may adjust the pressure using the regulator to provide more force or stop the movement.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

Memelihara Peralatan Pneumatik - Teknik Mekatronika

Dense phase and Lean (Dilute) Phase conveying system | Fly Ash conveying system| Ash Handling System

Mengenal Simbol Pneumatik dan Benda Aslinya #waginothok

Tutorial Elektopneumatik : pengenalan komponen dan cara instalasi sistem elektro-pneumatik

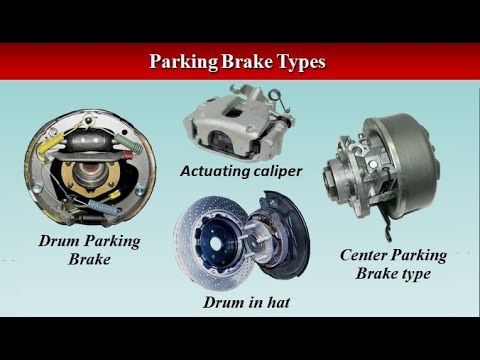

Brake Apply System [service Brake & Parking Brake]

HYDRAULIC ACTUATORS VICKERS HYDRAULIC TRAINING VEDIO BY MR PAUL COOK

5.0 / 5 (0 votes)