HOW TO - Fix Wobble & Adjust the Eccentric Nuts (3DPrinter)

Summary

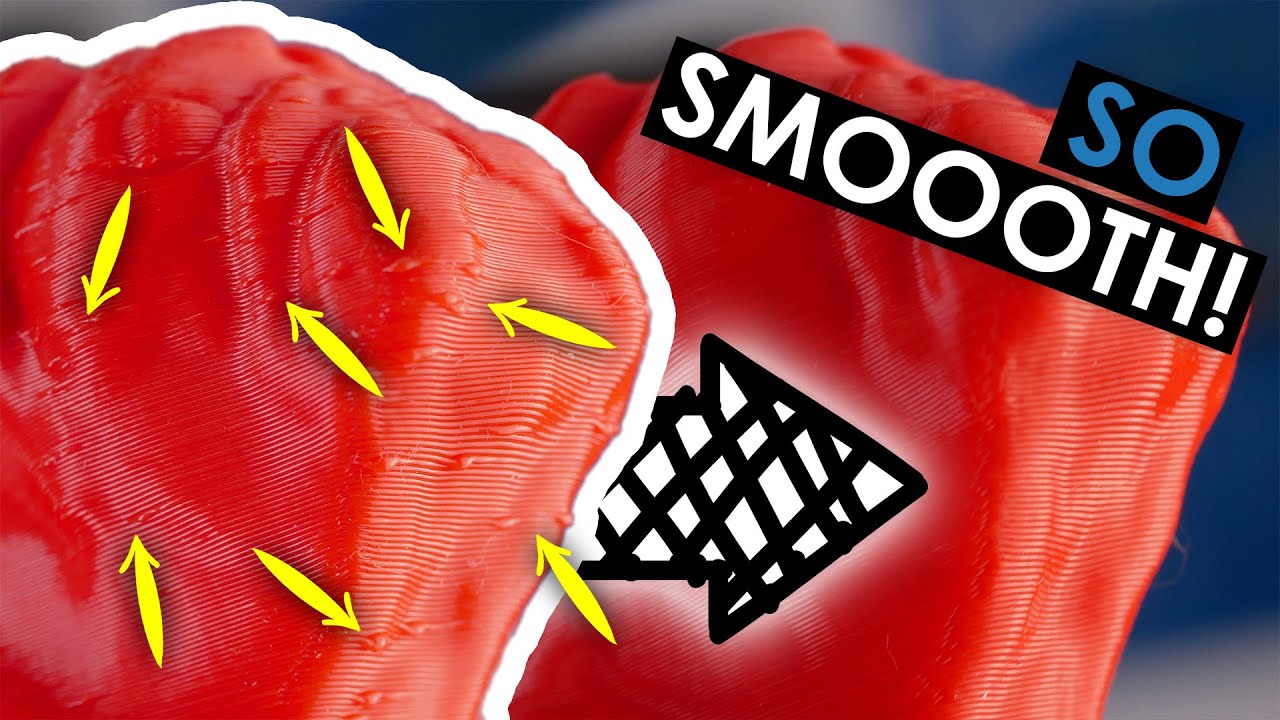

TLDRThis video script addresses a common issue faced by 3D printer users: wobbly carriage wheels that can degrade print quality. The video provides a detailed guide on how to adjust the grip of the wheels, emphasizing the importance of checking wheel grip after assembly. It dispels the myth that tightening wheel screws can solve the problem, instead highlighting the use of eccentric nuts to fine-tune wheel position. The script offers practical advice on achieving the right wheel grip, including how to recognize when the grip is too tight and how to allow wheels to recover from deformation. The video concludes with a reminder to follow the channel and social media for more helpful content.

Takeaways

- 📚 Always check the grip of the wheels on your 3D printer carriages after assembly.

- 🔧 Incorrect wheel grip adjustment can lead to quality issues in your 3D prints.

- 😯 Tightening wheel screws excessively does not improve grip and may cause damage.

- 🔄 Eccentric nuts are used to adjust the grip of the wheels on the carriages.

- 🧐 Identify adjustable wheels by locating the eccentric nuts, which are off-centered.

- 🕹️ Adjust the eccentric nuts until the wheel wobble stops, not beyond.

- 👆 Turn the eccentric nuts slightly more if wheels rotate with your fingers, until they stop.

- ⏱️ Allow the carriage to sit for a few minutes to let the wheels recover if they show signs of deformation.

- ⚖️ Some printers have two eccentric nuts per wheel to maintain parallelism and adjust grip.

- 🛠️ Follow the tips provided to fix wobble on carriages and ensure smooth wheel operation.

- 👍 Like the video and subscribe to the channel for more helpful content.

Q & A

What is the common issue that 3D printer users often face with their carriages?

-The common issue is that the carriages' wheels may have too much play or wobble, which can affect the quality of 3D prints.

Why is it important to check the grip of the wheels on a 3D printer carriage after assembly?

-Checking the grip is crucial because an incorrect wheel grip adjustment can lead to several quality issues on the prints, such as layer shifting or uneven extrusion.

What is the misconception some users have about adjusting the wheel grip on 3D printer carriages?

-Some users mistakenly believe that tightening the screws on the wheels will improve the grip, but this is not the case as wheel grip is adjusted using eccentric nuts, not by tightening screws.

How can you identify which wheels on a 3D printer carriage are adjustable?

-Adjustable wheels are identified by the presence of eccentric nuts. These nuts allow for fine-tuning of the wheel's grip on the print bed.

How do eccentric nuts work on 3D printer carriages?

-Eccentric nuts move the wheel closer to or away from the print bed profile when rotated. They help adjust the grip of the wheel without the need for tightening or loosening the wheel screws.

What is the recommended technique for adjusting the wheel grip using eccentric nuts?

-The recommended technique is to turn the eccentric nuts until the wheel wobble stops. You should rotate the wheels with your fingers to check for wobble and adjust accordingly.

What happens if the wheel grip is too strong on a 3D printer carriage?

-If the grip is too strong, the wheels may deform and create bumps on the surface when the carriage is moved. This can be corrected by loosening the grip slightly.

How long should you let the carriage sit after adjusting the wheel grip to allow the wheels to recover?

-You should let the carriage sit for several minutes to allow the wheels to recover and return to their normal shape.

What should you do if you notice that the wheel is not perfectly parallel with the metal profile on some 3D printers?

-If a wheel is not parallel, you will need to adjust both eccentric nuts on the wheel to ensure proper alignment and grip.

How can following the tips provided in the script help with 3D printer carriage issues?

-Following the tips will help fix wobble on carriages, ensuring that the wheels run smoothly and improving the overall print quality.

What are some ways viewers can support the creators of the video?

-Viewers can support the creators by subscribing to their channel, joining their Patreon page, or clicking on any affiliate links provided in the video description.

How can viewers stay updated with the latest videos from the creators?

-Viewers can stay updated by subscribing to the channel and following the creators on social media platforms like Facebook, Instagram, and Twitter.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

Bambu Lab A1 Mini - Assembly & First Print (Part 1)

Anycubic Kobra S1 - kolejne wrażenia po dwóch dniach oraz odpowiadam na Wasze pytania.

(How) I finally got rid of these blobs!

L-3.3: Printer-Spooler Problem | Process Synchronization Problem in Operating System

Weefun TINA 2 PLUS 3D Printer Review - Mods!

Comgrow T500, the only fast Klipper firmware 3D printer with a 500mm cube print volume, linear rails

5.0 / 5 (0 votes)