Turning Operation Explained | Engineering Videos | #learnengg #manufacturing #mechanicalengineering

Summary

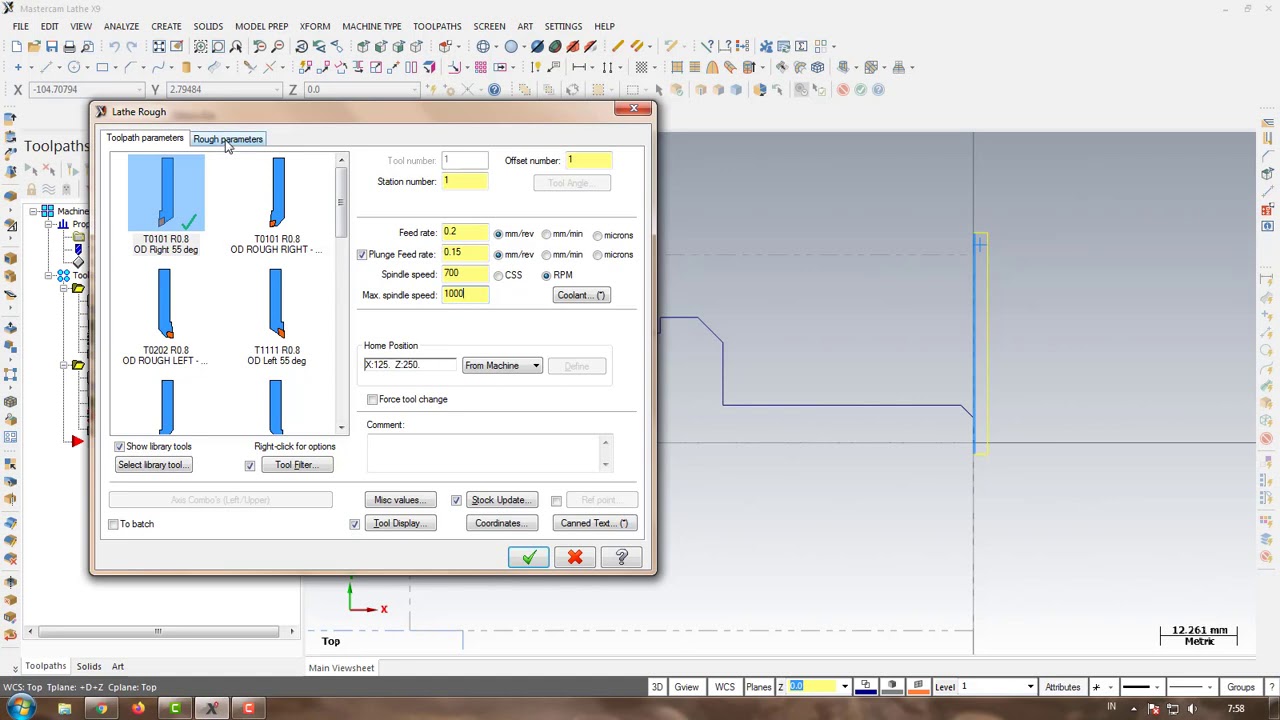

TLDRThis video delves into the L-turning operation, a machining process that removes excess material by rotating a workpiece against a cutting tool. The tool feeds across the workpiece, which is marked by a group, an indentation that can be square, round, or angular. The video explains the importance of the group in stopping the rotation and measuring the workpiece, showcasing the precision required in this manufacturing technique.

Takeaways

- ⚙️ L-turning is a machining operation used for material removal.

- 🔄 The workpiece is rotated against a cutting tool in this process.

- 🛠️ The cutting tool is fed crosswise against the rotating workpiece.

- 🔩 The group is a feature that holds an indentation in the workpiece.

- 🔲 Indentations can be of various shapes like square, round, or angular.

- ⏹️ The rotation of the workpiece is stopped to measure it after turning.

- 🔍 Turning operation requires precise control of the workpiece's rotation and tool feed.

- 🛑 The tool's feed direction is crucial for the quality of the turning operation.

- 🔧 The cutting tool's interaction with the workpiece determines the material removal rate and surface finish.

- 📏 Accurate measurement is essential after the turning operation to ensure the workpiece meets specifications.

Q & A

What is the primary purpose of the L-turning operation?

-The primary purpose of the L-turning operation is to remove excess material by rotating the workpiece against a cutting tool.

How does the workpiece interact with the cutting tool during L-turning?

-During L-turning, the workpiece rotates and the tool is fed crosswise against the rotating workpiece to remove material.

What is the role of the tool post in L-turning?

-The tool post holds the cutting tool in place and guides it as it feeds across the workpiece during the L-turning operation.

What type of indentation is typically found in the tool post?

-An indentation in the tool post can be square, round, or angular in shape, and it's used to stop the rotation of the workpiece.

Why is it necessary to stop the rotation of the workpiece during L-turning?

-Stopping the rotation of the workpiece allows for precise measurement and control of the machining process during L-turning.

What is the significance of the shape of the indentation in the tool post?

-The shape of the indentation in the tool post is significant as it determines how the workpiece is held and stopped during the L-turning process.

How does the crosswise feed of the tool contribute to the L-turning process?

-The crosswise feed of the tool against the rotating workpiece is essential for shaping the workpiece and achieving the desired dimensions in L-turning.

What is the importance of measuring the workpiece after stopping its rotation?

-Measuring the workpiece after stopping its rotation ensures that the machining operation has achieved the required dimensions and tolerances.

Can the L-turning operation be performed on workpieces of various shapes and sizes?

-Yes, the L-turning operation can be adapted to workpieces of various shapes and sizes, depending on the tooling and machine setup.

What safety measures should be considered during the L-turning operation?

-During the L-turning operation, safety measures such as proper workpiece clamping, tool post alignment, and operator protection should be strictly followed.

How does the L-turning operation differ from other turning operations?

-The L-turning operation is distinct from other turning operations in that it involves a specific crosswise feed of the tool against a rotating workpiece, often used for machining complex shapes.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade Now5.0 / 5 (0 votes)