Tips dan trik mengoperasikan mesin CNC bagi operator pemula

Summary

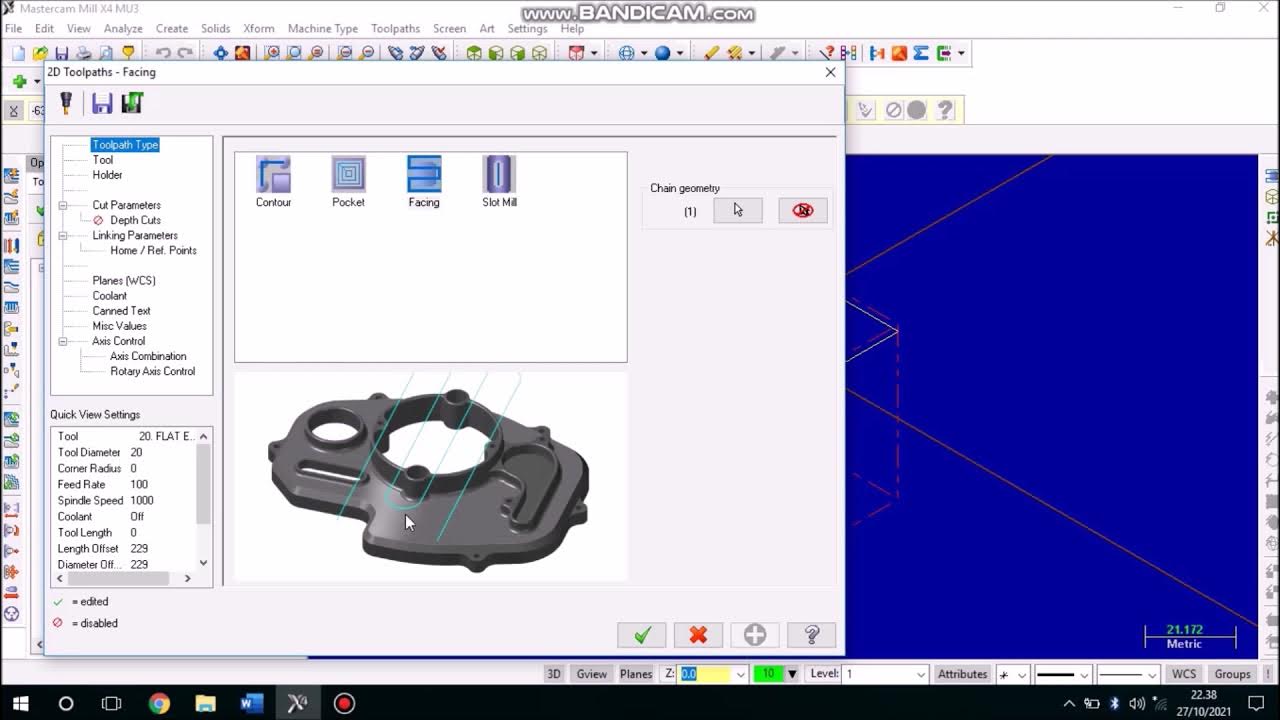

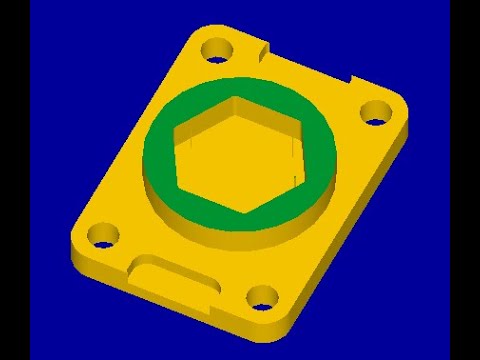

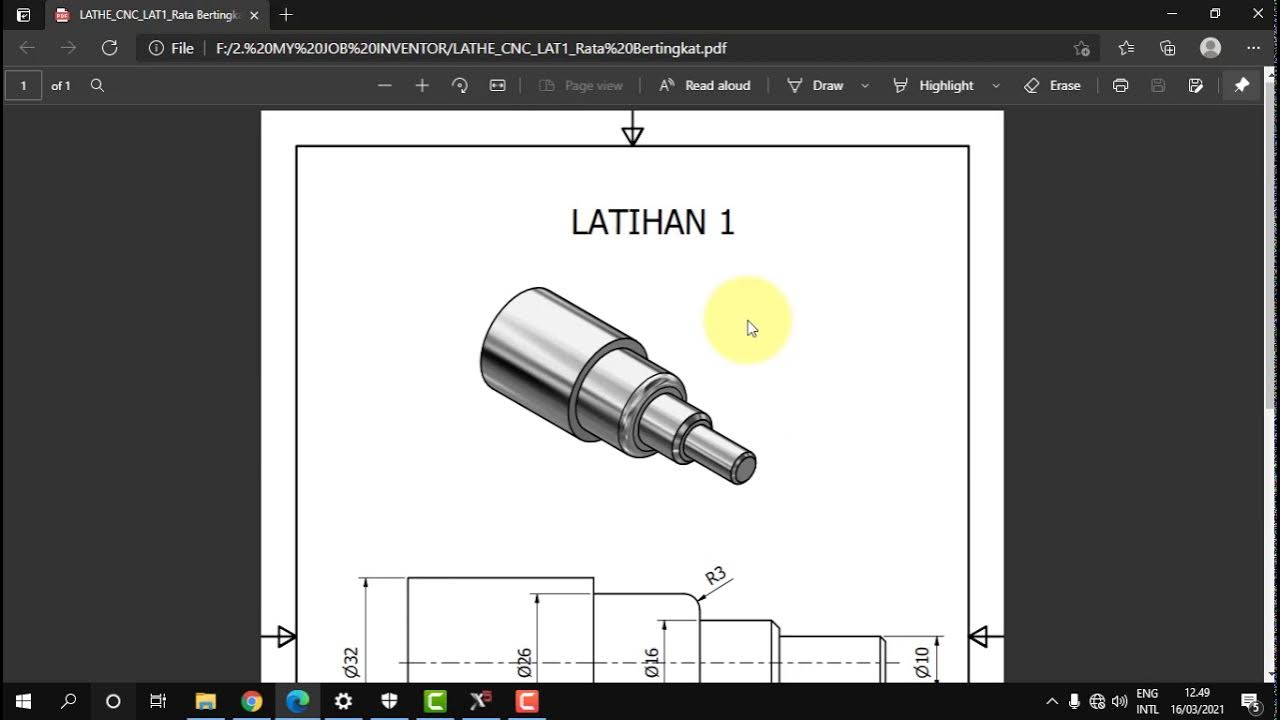

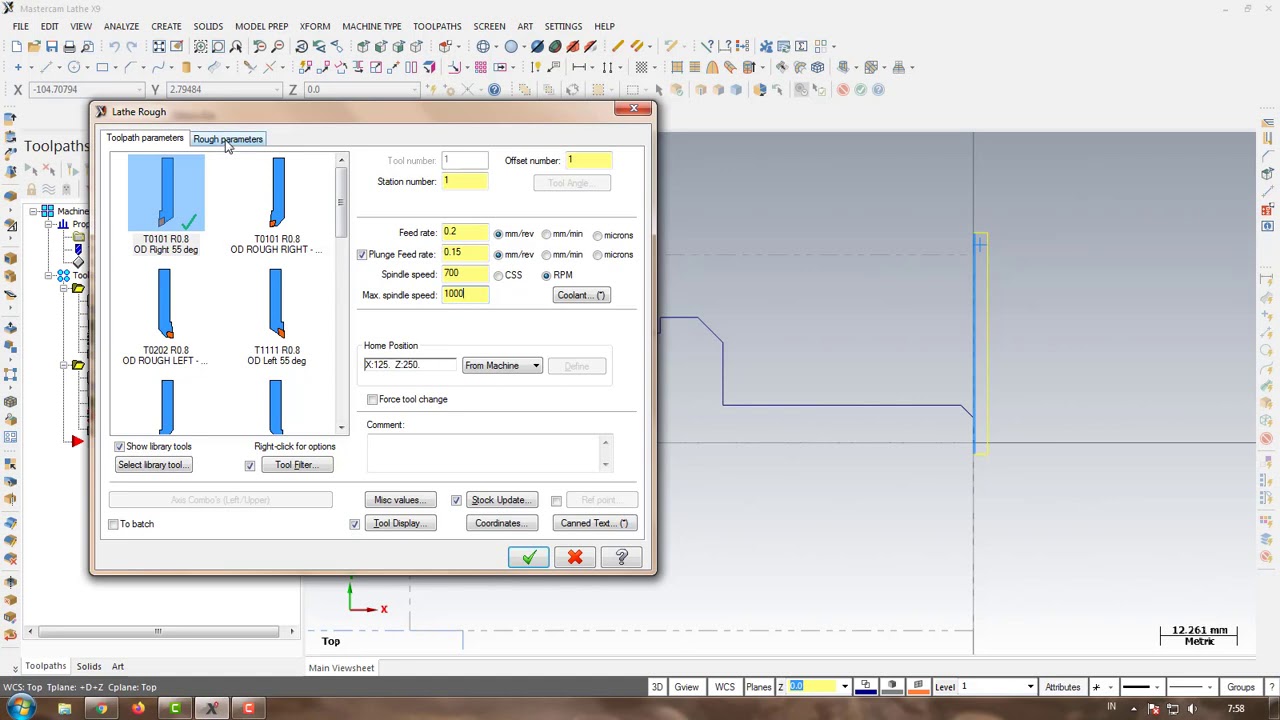

TLDRThis instructional video script outlines the process of running a CNC machine using Mastercam programs. It emphasizes selecting the correct toolpath, simulating the program, and editing the NC code for machine execution. The tutorial covers essential safety checks, including verifying machine settings, ensuring low spindle speeds, and adjusting feed rates. It also demonstrates how to execute the program in DNC mode, highlighting the importance of single block mode for safety and precision. The video concludes with a successful machining operation, reinforcing the importance of attentive operation and adherence to safety protocols.

Takeaways

- 😀 The script is a tutorial on running a CNC program created in Mastercam, focusing on the execution of a contouring program.

- 🛠️ The presenter explains the process of selecting and running a single operation due to differences in tooling, such as using an end mill for contouring and a drill for hole making.

- 💾 The tutorial involves saving the CNC program onto a flash drive, with a specific file naming convention to avoid confusion.

- ✂️ Before running the program on the machine, it's necessary to edit the NC code to remove unnecessary titles and adjust certain parameters for the machine's setup.

- 🔍 The presenter emphasizes the importance of checking the machine's settings before running the program, including ensuring the workpiece is correctly positioned.

- 🔧 The script outlines the steps to check the machine's settings using MDI mode, which includes inputting test commands to verify the machine's readiness.

- 🚫 Safety is a key theme, with instructions to ensure the machine is in a safe state before starting, including setting spindle speed to the lowest and ensuring rapid movements are minimized.

- 🔑 The use of 'single block' mode is highlighted for safely running the program line by line, allowing for manual control and verification at each step.

- 🔄 The script describes the process of loading the NC program from an external source like a USB or flash drive into the machine's DNC system.

- 🎛️ The importance of monitoring and controlling the machine's movements, spindle speed, and coolant during the machining process is discussed, with tips for adjusting these parameters as needed.

- 🏁 The tutorial concludes with a demonstration of the machining process, emphasizing the need for continuous supervision and control to ensure a successful operation.

Q & A

What is the purpose of the video script?

-The video script is intended to guide viewers through the process of running a CNC machine using a program created in Mastercam. It includes steps for simulation, file handling, and execution of the program on the machine.

Why is it necessary to simulate the program before running it on the machine?

-Simulating the program before running it on the machine is crucial to verify the accuracy of the program and to ensure that it will perform correctly without causing any damage to the machine or the workpiece.

What is the significance of selecting a single program to run instead of all programs at once?

-Selecting a single program is significant because different programs may use different cutting tools, such as end mills or drills with different diameters. Running one at a time allows for proper tool setup and reduces the risk of errors.

Why is it important to check the machine settings before running a program?

-Checking the machine settings is important to ensure that the workpiece is correctly positioned and that the machine is set up according to the program's requirements, which helps prevent errors and potential damage during the machining process.

What is meant by 'single block' mode in the context of the script?

-In 'single block' mode, the CNC machine reads and executes one line of the program at a time. This allows the operator to monitor and control the machine's movements step by step, ensuring safety and accuracy.

How does the operator ensure that the program runs smoothly and safely on the CNC machine?

-The operator ensures smooth and safe operation by setting the spindle speed to the lowest, checking the feed rate, ensuring rapid movements are as minimal as possible, and activating the 'single block' mode for controlled execution.

What is the role of the 'MDI' mode in the process described in the script?

-MDI (Manual Data Input) mode is used to manually input and execute short commands or to check the machine settings before running the full program. It allows the operator to test individual commands without engaging the entire program.

Why is it recommended to delete certain lines from the NC code before running it on the machine?

-Certain lines in the NC code, such as comments or tool change commands, may not be necessary for the actual machining process. Deleting them can help prevent confusion and ensure that the machine operates efficiently.

What does the acronym 'DNC' stand for, and how is it used in the context of the script?

-DNC stands for Direct Numerical Control. It refers to the process of running a program directly from an external memory source, such as a USB or flash disk, rather than from the machine's internal memory.

How does the operator know when the machining process is complete?

-The operator can monitor the progress of the machining process through the machine's display, which shows the current position and depth of the tool. The process is complete when the tool reaches the programmed depth, and the machine automatically stops the spindle and returns to the home position.

What safety measures are emphasized during the execution of the CNC program?

-Safety measures emphasized include keeping the emergency stop button within reach, ensuring that the 'single block' mode is activated for step-by-step execution, and maintaining control over the machine's movements throughout the machining process.

Outlines

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraMindmap

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraKeywords

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraHighlights

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraTranscripts

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraVer Más Videos Relacionados

5.0 / 5 (0 votes)