Understanding the Finite Element Method

Summary

TLDRThis video delves into the finite element method, a crucial tool in engineering for solving complex structural mechanics problems. It explains how this numerical technique breaks down a body into smaller elements, creating a mesh to simplify equilibrium calculations. The script covers element types, degrees of freedom, and stiffness matrices, highlighting the process from problem definition to post-processing. It also touches on the derivation of stiffness matrices and the role of software in handling complex calculations, providing a foundational understanding of this powerful analysis method.

Takeaways

- 🔍 The finite element method (FEM) is a numerical technique used by engineers to solve complex structural and mechanics problems that cannot be easily solved analytically.

- 🌐 FEM is widely applied across major engineering industries for various analyses, including static, dynamic, buckling, modal, fluid flow, heat transfer, and electromagnetic problems.

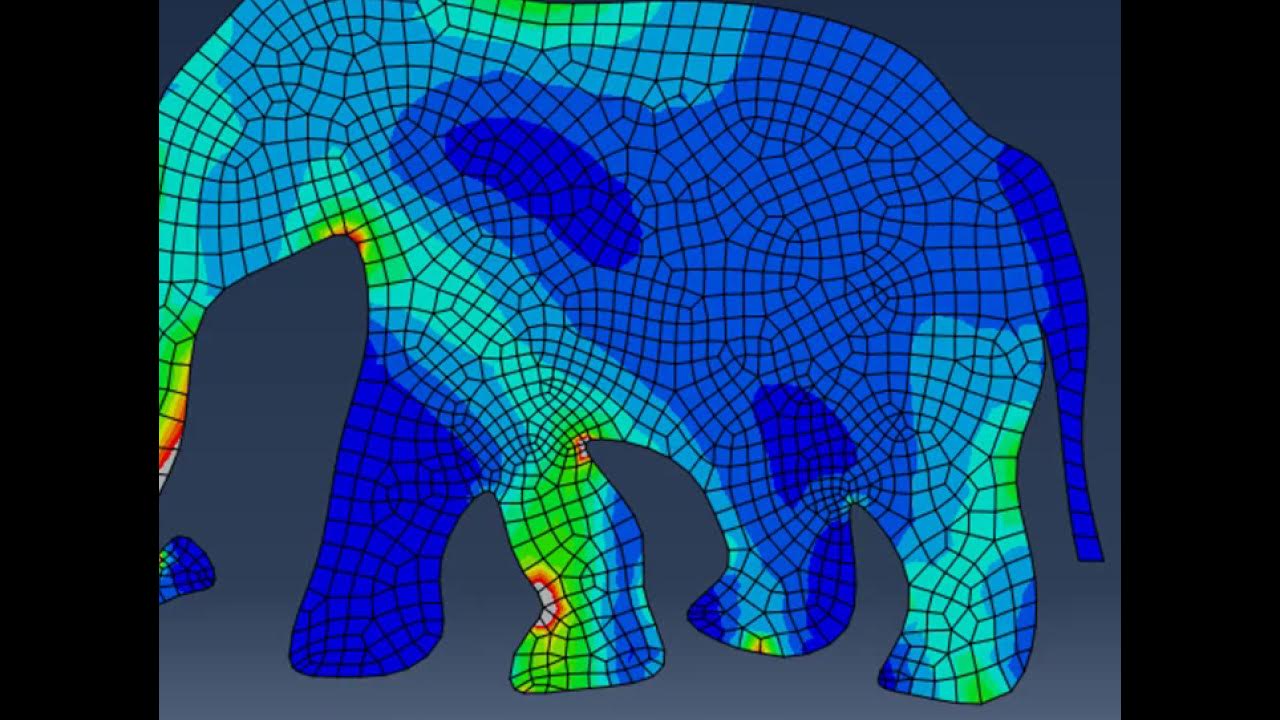

- 🛠️ The method involves breaking down a complex structure into smaller, simpler elements connected at nodes, creating a 'mesh' that can be analyzed for equilibrium.

- 📐 FEM allows for the calculation of 'field variables' such as stresses, strains, and displacements within a structure under load.

- 📊 Different element shapes like triangular, quadrilateral, solid, and line elements can be used in FEM, chosen based on the specific analysis requirements and the geometry of the structure.

- 🔗 The stiffness matrix, derived from Hooke's law, is crucial for FEM as it relates the nodal forces and moments to the nodal displacements within each element.

- 🧩 The global stiffness matrix is assembled from individual element stiffness matrices, considering the connectivity and continuity of the elements in the mesh.

- 🔄 FEM involves iterative processes for solving the global stiffness matrix, often using methods like the conjugate gradient method due to the large size and sparse nature of the matrix.

- 📉 Post-processing of the nodal displacements obtained from FEM allows for the calculation of secondary outputs such as stress and strain throughout the structure.

- 🔧 Engineers play a critical role in FEM by defining the problem, selecting appropriate element types, ensuring a suitable mesh, and validating the results for accuracy and reliability.

Q & A

What is the finite element method and why is it important in engineering?

-The finite element method is a powerful numerical technique that uses computational power to calculate approximate solutions to complex structural mechanics problems. It's important in engineering because it allows for the analysis of complex geometries, loads, or materials that cannot be solved using traditional analytical methods.

How does the finite element method handle complex problems that traditional analytical methods cannot solve?

-The finite element method handles complex problems by discretizing the body into small elements connected at nodes, allowing the equilibrium requirement to be satisfied over a finite number of discrete elements instead of continuously over the entire body.

What are the different types of elements used in the finite element method?

-Different types of elements used include triangular and quadrilateral surface elements for modeling thin surfaces, solid elements for three-dimensional bodies, and line elements. The choice of element depends on the specific scenario being analyzed and requires expertise.

Why is the concept of equilibrium important in the finite element method?

-The concept of equilibrium is important because internal stresses within a body develop to maintain equilibrium over any volume of the body. This concept is used to calculate field variables such as stresses, strains, and displacements within the body.

What is a degree of freedom in the context of the finite element method?

-A degree of freedom in the finite element method refers to the number of independent displacement components possible at a node. For example, in a two-dimensional case with beam elements, each node can translate along the X and Y axes and rotate about the Z axis, resulting in three degrees of freedom per node.

How is the stiffness matrix of an element derived in the finite element method?

-The stiffness matrix of an element is derived by enforcing equilibrium and can be obtained through various methods such as the direct method, the principle of minimum potential energy, or the Galerkin method of weighted residuals. These methods help define how much each node in the element will displace for a set of forces and moments applied to the nodes.

What is the significance of the global stiffness matrix in the finite element method?

-The global stiffness matrix is significant because it defines how the entire structure will displace when loads are applied. It is assembled from individual element stiffness matrices based on how the elements are connected together, and it is used to solve for the displacements at each node in the structure.

How are boundary conditions applied in the finite element method?

-Boundary conditions in the finite element method are applied by defining known displacements at specific nodes, typically because certain degrees of freedom are fixed. These conditions are used to solve the global stiffness matrix equation to obtain the displacements at each node.

What is the role of software in the finite element method?

-Software plays a crucial role in the finite element method by automating complex calculations such as deriving element stiffness matrices, assembling the global stiffness matrix, and solving the model. It also aids in post-processing to obtain results and validating the model, which would be impossible to do manually for complex models.

How does the finite element method account for different material properties and loads?

-The finite element method accounts for different material properties and loads by incorporating these factors into the element stiffness matrix calculations. The material properties affect the element's resistance to deformation, while the loads determine the forces and moments applied to the nodes.

What is the purpose of shape functions in the finite element method?

-Shape functions in the finite element method are used to describe how displacements and other field variables vary inside the element. They are usually polynomial assumptions that interpolate values at the nodes to calculate values within the element, which is necessary for methods like the Galerkin method.

Outlines

此内容仅限付费用户访问。 请升级后访问。

立即升级Mindmap

此内容仅限付费用户访问。 请升级后访问。

立即升级Keywords

此内容仅限付费用户访问。 请升级后访问。

立即升级Highlights

此内容仅限付费用户访问。 请升级后访问。

立即升级Transcripts

此内容仅限付费用户访问。 请升级后访问。

立即升级浏览更多相关视频

Derive Time Independent SCHRODINGER's EQUATION from Time Dependent one

FOURIER SERIES LECTURE 1 | STUDY OF DEFINITION AND ALL BASIC POINTS @TIKLESACADEMY

Mata Kuliah - Analisa Dimensi - FT

Lec-3: What is Automata in TOC | Theory of Computation

What is Finite Element Analysis? FEA Explained

FEA 23: 2-D Triangular Elements

5.0 / 5 (0 votes)