CBME 1 | Lesson 2 | Part 1/3

Summary

TLDRThis lesson delves into the transition of quality control, emphasizing its importance in meeting customer satisfaction through product and service excellence. It introduces DFSS (Design for Six Sigma), detailing its four key phases: Concept Development, Design for Development, Design Organization, and Design Verification. The video also discusses the significance of creativity and innovation in product development, explaining how they can lead to new or improved products. Additionally, it covers QFD (Quality Function Deployment) for ensuring customer needs are met and DFMEA (Design Failure Mode and Effects Analysis) for identifying and addressing potential product failures.

Takeaways

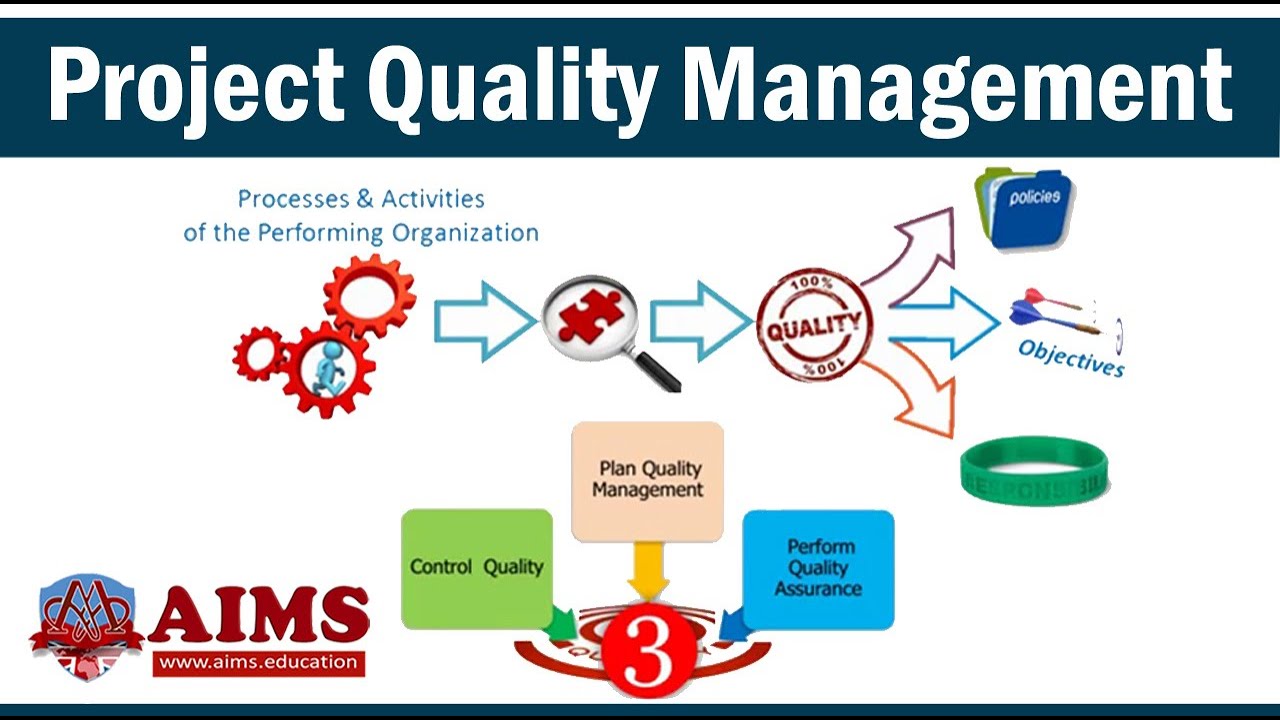

- 🔍 Quality Control is crucial for ensuring products and services meet customer expectations and standards.

- 🛠️ Tools and techniques in quality control include activities and techniques to achieve, sustain, and improve product and service quality.

- 🎯 Design for Six Sigma (DFSS) is a set of tools and methodologies aimed at developing products and services that meet customer needs and company objectives.

- 💡 The first phase of DFSS is Concept Development, which involves planning the development process.

- 🛠️ The Design for Development phase is about executing the development process based on the plan.

- 👥 Design Organization involves considering the people in the company who will execute the design.

- 🔍 Design Verification checks if the plans and executed plans meet the company's goals and objectives.

- 💡 Creativity and innovation are key in product development, with innovation involving new concepts or additional features to existing products.

- 📱 Examples of innovation include entirely new categories of products, first of its type in a product category, significant improvements in existing technology, and modest improvements in existing products.

- 🤝 Quality Function Deployment (QFD) is a methodology that ensures customer requirements are met by improving communication and teamwork across different stages of production.

- 🔎 Design Failure Mode and Effects Analysis (DFMEA) helps identify potential failures in design, their effects on customers, likelihood of occurrence, potential causes, and corrective actions.

Q & A

What is the main focus of the lesson on 'Transition of Quality Control and its Significance'?

-The lesson focuses on the importance of quality control in ensuring products and services meet customer expectations and standards. It covers tools and techniques used in quality control, including design and production processes.

What does the acronym DFSS stand for and what is its purpose?

-DFSS stands for Design for Six Sigma, a set of tools and methodologies aimed at developing products and services that meet customer needs and achieve company objectives.

What are the four principal activities in the DFSS process?

-The four principal activities in the DFSS process are: 1) Concept Development, 2) Design for Development, 3) Design Organization, and 4) Design Verification.

How does the concept of creativity play a role in product development?

-Creativity in product development involves seeing things in a new or novel way, understanding customer needs and wants, and coming up with innovative solutions or products based on research and analysis.

What is innovation in the context of product development?

-Innovation refers to the process of introducing new concepts or features to existing products, which can include entirely new categories of products, significant improvements, or modest enhancements to existing products.

What is QFD and how does it contribute to meeting customer requirements?

-QFD stands for Quality Function Deployment, a methodology that ensures customer requirements are met by improving communication and teamwork across different departments involved in the production process.

What is DFMEA and why is it important in quality control?

-DFMEA stands for Design Failure Mode and Effects Analysis, a process used to identify potential failures in design elements or functions. It is important for anticipating and addressing issues that could lead to customer dissatisfaction.

What are the key components assessed in a DFMEA analysis?

-In a DFMEA analysis, key components assessed include failure mode, effect of failure on customers, likelihood and occurrence of failure, detection rating, potential causes of failure, and corrective actions and controls.

How does the scale used in DFMEA help in addressing product issues?

-The scale in DFMEA, ranging from one to ten, helps prioritize issues based on severity. A higher score indicates a more serious problem that requires immediate attention, while lower scores still need to be addressed to prevent potential issues.

What is the significance of the design organization phase in DFSS?

-The design organization phase is significant as it involves considering the people within the company who will execute the design. It ensures that employees and subordinates are aligned with the execution of the development process.

How does the concept of innovation relate to the improvement of existing products?

-Innovation in product improvement can involve adding new features to existing products, creating entirely new categories of products, or making significant or modest improvements to existing technologies to enhance customer satisfaction and market competitiveness.

Outlines

此内容仅限付费用户访问。 请升级后访问。

立即升级Mindmap

此内容仅限付费用户访问。 请升级后访问。

立即升级Keywords

此内容仅限付费用户访问。 请升级后访问。

立即升级Highlights

此内容仅限付费用户访问。 请升级后访问。

立即升级Transcripts

此内容仅限付费用户访问。 请升级后访问。

立即升级5.0 / 5 (0 votes)