How to Wire Up Ethernet Plugs the EASY WAY! (Cat5e / Cat6 RJ45 Pass Through Connectors)

Summary

TLDRThis video script offers a tutorial on the improved method of crimping RJ45 plugs onto Ethernet cables using pass-through or snap plugs, which eliminates the need for guessing wire length and reduces the risk of misalignment. It details the necessary tools, including a blade-equipped crimping tool and a cable tester, and provides a step-by-step guide on cutting, stripping, arranging, and verifying the correct wiring order according to T-568A or T-568B standards. The process ensures a neat and functional cable every time, with strain relief boots to prevent damage. The script also emphasizes the importance of testing the cable for proper connections before use.

Takeaways

- 🔌 The video discusses a better way to attach RJ45 plugs to Ethernet cables using pass-through or snap plugs.

- 🛠️ Essential tools for the process include a drum of Ethernet cable (Cat5e, Cat6, or Cat6a), RJ45 pass-through plugs, strain relief boots, a crimping tool with a blade, snips, a mini wire stripper and punch down tool, and a cable tester.

- ✂️ The process starts with cutting the required length of cable, leaving excess to account for trimming and potential mistakes.

- 🧵 Network cables consist of 4 twisted pairs of color-coded wires, with Cat6 cables having a plastic core to reduce crosstalk.

- 📏 After stripping the outer jacket, the plastic crosstalk separator and ripcord thread are removed, and the wires are untwisted and straightened.

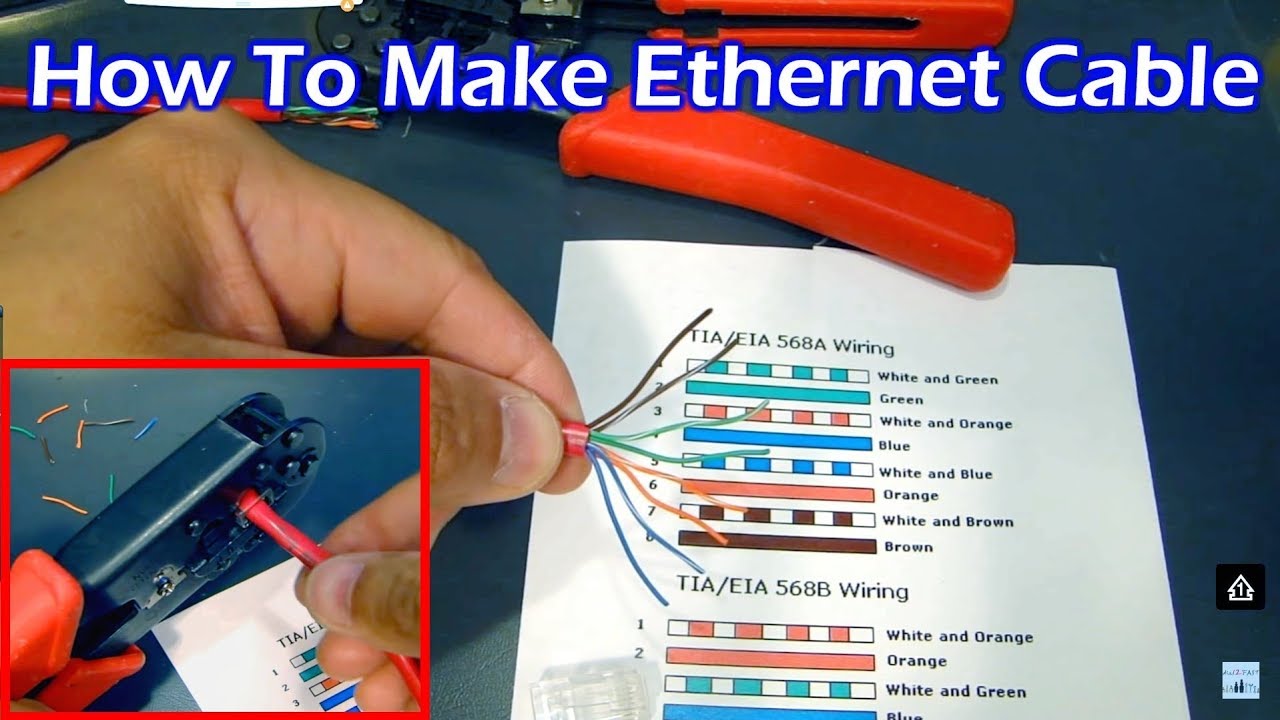

- 📋 The correct order of wires must be followed, with two main standards, T-568A and T-568B, with the key being consistency between cable ends.

- 🔄 The video suggests using T-568B due to its widespread use, detailing the specific color order for the wires.

- 🔄 When adding to an existing setup, it's important to match the wiring standard already in use for consistency.

- 📐 The pass-through plug allows for checking the wire order before crimping, ensuring alignment and preventing the need to start over.

- 🔧 The crimping tool not only secures the plug but also trims excess wire, resulting in a neat finish.

- 🔄 The process is repeated for the other end of the cable, with the same wiring order, followed by testing with a cable tester to verify correct connections.

- 🚫 The cable tester checks for proper wiring sequence and functionality, identifying any mistakes in the process.

Q & A

What is the main problem with traditional RJ45 plugs and crimping methods?

-Traditional RJ45 plugs require precise measurement and can lead to misalignment of wires inside, causing the need to start over, wasting plugs and shortening the cable with each failure.

What type of RJ45 plug is recommended in the script for a better crimping experience?

-Pass-through RJ45 plugs, also known as snap plugs, are recommended for their open ends that allow for double-checking the wire order before crimping.

What are the essential tools needed for the improved RJ45 crimping process described in the script?

-The essential tools include a drum of Ethernet cable (Cat5e, Cat6, or Cat6a), pass-through RJ45 plugs, strain relief boots, an RJ45 crimping tool with a blade, a pair of snips, a mini wire stripper and punch down tool, and a cable tester.

Why are strain relief boots used in the RJ45 crimping process?

-Strain relief boots are used to prevent the clip lever on the RJ45 plug from snapping, providing additional durability to the cable connection.

What is the purpose of the cable tester mentioned in the script?

-The cable tester is essential to verify that all 8 connections in the cable are correct and working before using it in a network setup.

How much excess cable should be left when cutting for the cable run?

-A generous amount of excess should be left, partly because a few centimeters will be chopped from either end, and also to ensure there is enough length in case the cable is found to be too short.

What are the two main RJ45 wiring standards mentioned in the script, and what is the key difference between them?

-The two main standards are T-568A and T-568B. The key difference is that the greens and oranges trade places in their wiring order.

Why is it important to maintain the same wiring standard on both ends of a cable?

-Maintaining the same wiring standard on both ends ensures that the cable works correctly and is consistent with any existing setup, making it easier for future use and troubleshooting.

How does the pass-through RJ45 plug help prevent misalignment of wires during the crimping process?

-The open ends of pass-through plugs allow wires to be poked through, enabling a double-check of the order before crimping, and guaranteeing that all wires align correctly and reach the tip of the plug.

What should be done if the wire order is found to be incorrect after inserting into the pass-through plug?

-If the wire order is incorrect, the plug can be slid off, the wires corrected, and reinserted without wasting the plug or shortening the cable.

How does the cable tester confirm that the cable is working perfectly?

-The cable tester sends a pulse down each wire from the Master to the Remote, checking all 8 wires individually. A correct sequence from 1 to 8 on both ends indicates that the cable is wired correctly and functioning properly.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

Network Tools - CompTIA A+ 220-1101 - 2.8

How To Make Ethernet Cable RJ45 - Straight Through & Crossover

Instalasi Jaringan Kabel - Sistem Informatika, Jaringan, dan Aplikasi

Step by Step on how to make Crossover Cable.

FAZ MUITA DIFERENÇA! MOTOR MACIO E SEM FALHAS, MELHORA CONSUMO E DESEMPENHO!

Cara crimping kabel LAN / Press Konektor RJ45 Anti gagal mudah dan rapih untuk pemula 100% bisa

5.0 / 5 (0 votes)