How CEMENT is Made | in FACTORIES

Summary

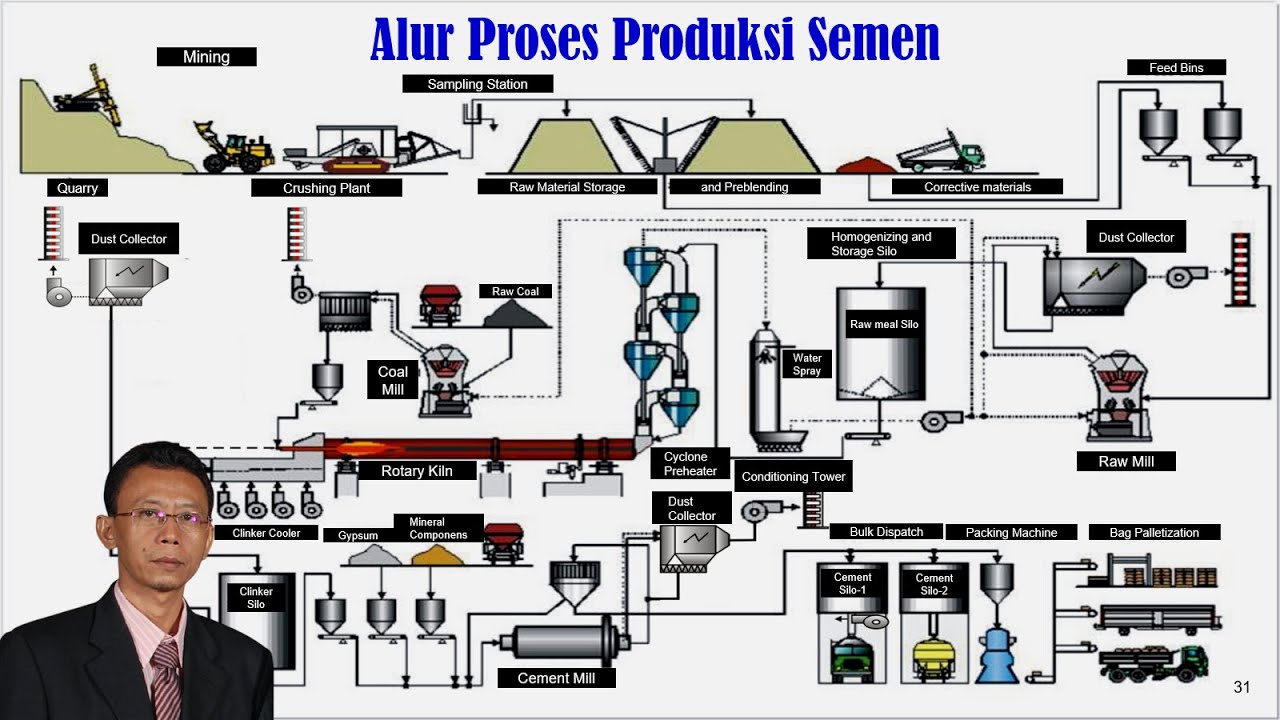

TLDRThis video delves into the fascinating process of cement production, starting with the extraction and processing of raw materials like limestone and clay, and leading to the creation of ordinary Portland cement. It details each step, from crushing and grinding the raw materials to the formation of clinker in a rotary kiln, and finishing with the addition of gypsum to control the setting time. The video also highlights the importance of aggregates, admixtures, and the precise mixing of ingredients in creating high-quality concrete. Cement’s versatility and importance in construction make it a crucial material worldwide, with a multibillion-dollar industry supporting its global use.

Takeaways

- 😀 Cement is a primary ingredient in concrete, acting as a binding agent to hold water and aggregates together.

- 😀 The most commonly used type of cement is Ordinary Portland Cement, named after the stone quarried on the Isle of Portland in England.

- 😀 Cement production starts with the extraction of limestone and clay, which are crushed and mixed to form a raw meal.

- 😀 The raw meal is heated in a preheater tower and undergoes partial calcination before entering a rotary kiln where temperatures reach 1450°C (2642°F).

- 😀 The high temperature in the kiln causes chemical reactions that form clinker, which consists of calcium silicates, aluminates, and ferrites.

- 😀 After cooling, the clinker is ground with gypsum and other additives like fly ash to produce cement powder, which controls its setting time.

- 😀 Cement production requires constant quality checks through physical and chemical tests to ensure it meets industry specifications.

- 😀 Aggregates, primarily gravel and sand, make up 75% of concrete by volume and are key to improving the strength and consistency of the final mix.

- 😀 Admixtures, such as plasticizers, accelerators, and retarders, can be added to concrete to modify its properties, including workability and setting time.

- 😀 Concrete mix design is a specialized field that focuses on determining the right proportion of materials to achieve the desired strength and durability.

- 😀 Once mixed, concrete must be carefully placed, compacted, and cured to ensure it gains the necessary strength over time, often taking days or weeks.

Q & A

What is the main difference between cement and concrete?

-Cement is a primary raw material used in the production of concrete. Concrete, on the other hand, is a mixture of cement, water, and aggregate (such as sand and gravel).

What is the most commonly used type of cement?

-The most commonly used type of cement is ordinary Portland cement, which was named after the stone quarried on the Isle of Portland in Dorset, England.

What are the primary raw materials used in cement production?

-The primary raw materials for cement production are limestone and clay, which are extracted from quarries.

How are limestone and clay processed in cement production?

-Limestone and clay are extracted from the earth, crushed into smaller pieces, and then mixed to form a raw meal. This raw meal is ground into a fine powder to enhance chemical reactions.

What role does the rotary kiln play in cement production?

-The rotary kiln is a cylindrical furnace where the raw materials are heated to around 1450°C, undergoing complex chemical reactions that result in the formation of clinker, the key component of cement.

Why is clinker cooling important in cement manufacturing?

-Cooling the clinker is essential to prevent the formation of undesirable crystals and to maintain the quality of the final cement product.

What is gypsum's role in cement production?

-Gypsum is added to ground clinker to control the setting time of the cement, ensuring it hardens at a controlled rate.

How is aggregate used in concrete?

-Aggregate, composed of gravel and sand, makes up about 75% of concrete by volume. It is used to provide strength and consistency by filling the spaces between the gravel and improving bonding.

What are admixtures and why are they important in concrete production?

-Admixtures are chemicals added to concrete to improve its properties. These include plasticizers (for better workability), accelerators/retarders (to adjust setting times), and fibers (to increase tensile strength).

What is the purpose of curing in concrete production?

-Curing is the process of maintaining moisture and temperature conditions to allow cement to hydrate properly, gradually increasing the strength and durability of the concrete.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

Sering Lihat Tapi Gak Tau Proses Pembentukannya? Begini Cara Pembuatan Semen Dari Awal Hingga Akhir

Cement Manufacturing

Alur Proses Produksi Semen (Tahapan Proses Produksi Semen)_Indonesia

How Cement is Made? Cement Production Process 🪨

Cement Raw Materials Grinding Process (Raw Mill System) _ English Version

Process de fabrication du ciment - Ciments Calcia

5.0 / 5 (0 votes)