Cement Raw Materials Grinding Process (Raw Mill System) _ English Version

Summary

TLDRIn this video, Pardi Rosyid from Parros Cement Techno Channel explains the process of milling cement raw materials. The video covers the essential components of the raw materials, such as limestone, silica, clay, and iron ore, and their grinding process. It details the equipment used, including Tube Mills and Vertical Roller Mills, and discusses supporting systems like reclaimers, conveyors, separators, and dust collection systems. The raw meal produced is stored in a silo for further processing. The video aims to provide a clear understanding of the raw material milling process and the machinery involved.

Takeaways

- 😀 Raw Mill System is crucial for grinding raw materials into raw meal, which is then used in the combustion process of the Kiln system.

- 😀 The main raw materials in cement production are Limestone (82%), Silica (12%), Clay (4%), and Iron Ore (2%).

- 😀 The goal of grinding is to achieve a fineness of 12-14% on a 90-micron sieve and maintain a moisture content of less than 1%.

- 😀 Two main types of equipment are used in the milling process: Tube Mill and Vertical Roller Mill.

- 😀 Tube Mill involves steel balls inside a steel cylinder to grind materials through impact and friction.

- 😀 Vertical Roller Mill uses rollers and a rotating table for grinding, with pressure applied to the material by the rollers.

- 😀 Both mills separate fine and coarse materials using a Separator, with coarse material sent back for further milling.

- 😀 Supporting equipment includes Reclaimers (Front Bridge, Side Scraper, Circular Bridge), Belt Conveyors, and Dust Collecting Systems.

- 😀 Reclaimers help pull materials from storage and feed them into the milling process. There are three types: Front Bridge, Side Scraper, and Circular Bridge.

- 😀 Dust Collecting Systems (ESP and Filter Baghouse) capture product material from the milling process to prevent contamination and improve air quality.

- 😀 The Bucket Elevator transports materials vertically, including raw meal products, to the Silo, which also helps with homogenization of raw meal quality.

Q & A

What is the primary function of the Raw Mill System in cement production?

-The Raw Mill System is responsible for grinding raw materials into raw meal, which serves as feed for the combustion process or the Kiln system.

What are the main raw materials used in cement production, and what are their approximate percentages?

-The main raw materials used in cement production are Limestone (82%), Silica (12%), Clay (4%), and Iron Ore (2%).

What is the required fineness for raw meal in the cement production process?

-The required fineness for raw meal is 12 to 14% on a 90-micron sieve, with a moisture content of less than 1%.

What are the two main types of equipment used in the raw material milling process?

-The two main types of equipment used in the raw material milling process are Tube Mill and Vertical Roller Mill.

How does the Tube Mill function in the raw material milling process?

-The Tube Mill is a steel cylinder lined with a liner and filled with steel balls. It grinds materials through the rotation of the mill and the impact and friction from the steel balls and the liner.

How does the Vertical Roller Mill differ from the Tube Mill in the milling process?

-The Vertical Roller Mill uses 3 to 6 rollers and a rotating table as grinding mediums. The grinding occurs through pressure from the rollers on the material above the table.

What role do Separators play in the raw material milling process?

-Separators separate coarse and fine materials after milling. The coarse material is returned to the mill for re-milling, while the fine material becomes the product.

What is the function of the Reclaimer in the raw material milling system?

-The Reclaimer pulls material from storage piles and transfers it into the feeding bin or directly into the raw material milling process.

What are the different types of reclaimers used in the milling process?

-The three types of reclaimers are the Front Bridge Reclaimer, Side Scraper Reclaimer, and Circular Bridge Reclaimer, each designed for different methods of retrieving materials from storage piles.

What is the purpose of the Dust Collecting System in the raw material milling process?

-The Dust Collecting System captures dust and fine particles from the milling process. It includes systems like the Electro Static Precipitator (ESP) and the Filter Baghouse.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

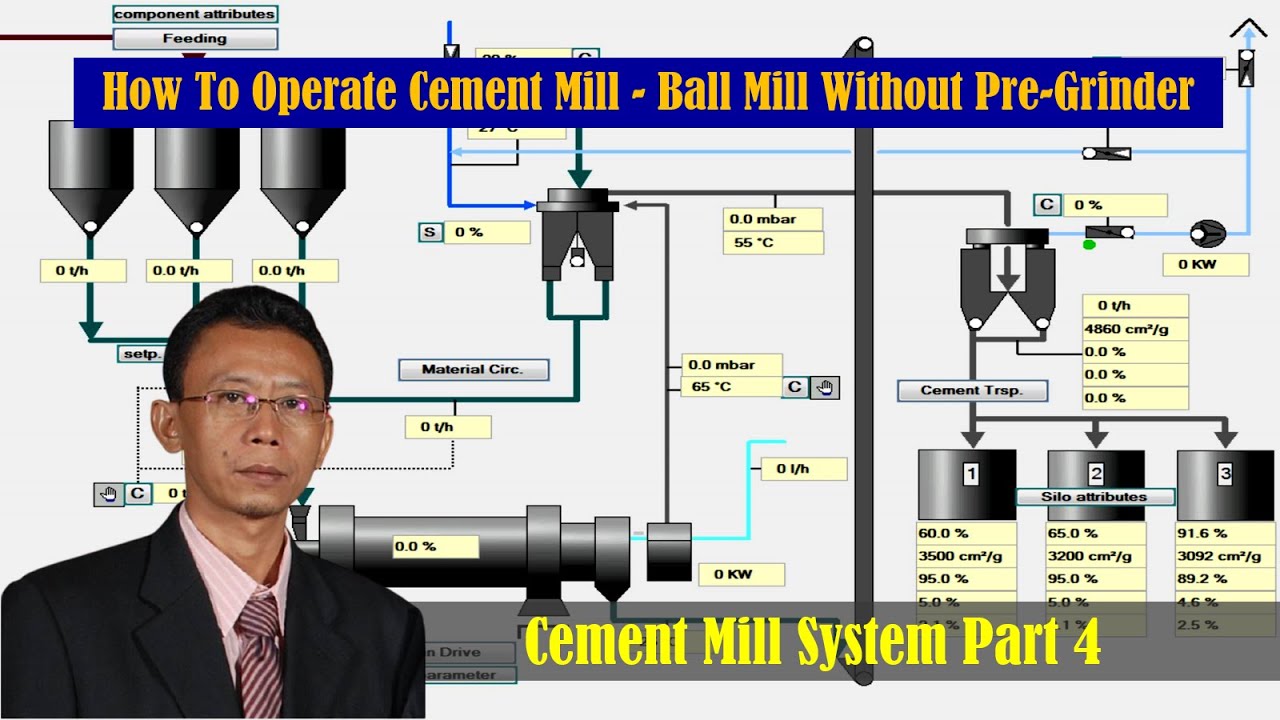

Cement Milling Process Ball Mill Operation Using Simulator _ English Version

Cement Manufacturing Process with the Portland Cement Association

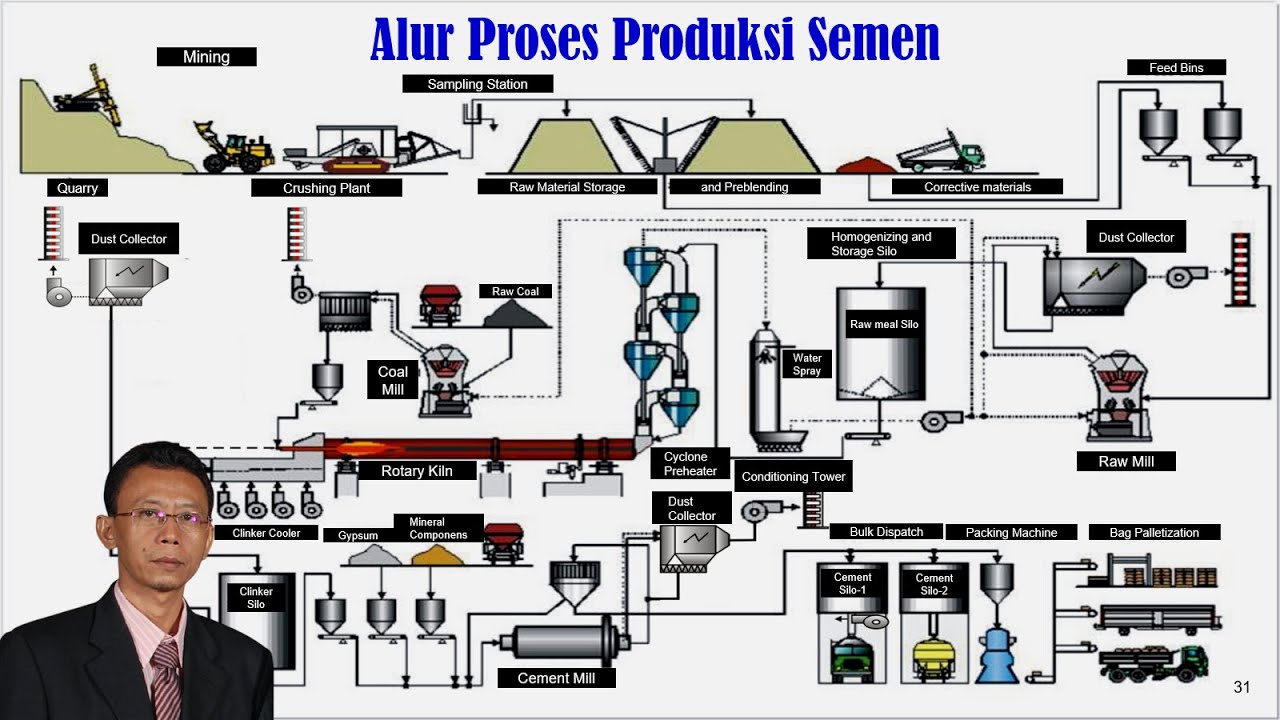

Alur Proses Produksi Semen (Tahapan Proses Produksi Semen)_Indonesia

How Cement Is Made In Factories?

Cement Manufacturing

MinuteCement - Introduction to cement chemistry

5.0 / 5 (0 votes)