Process de fabrication du ciment - Ciments Calcia

Summary

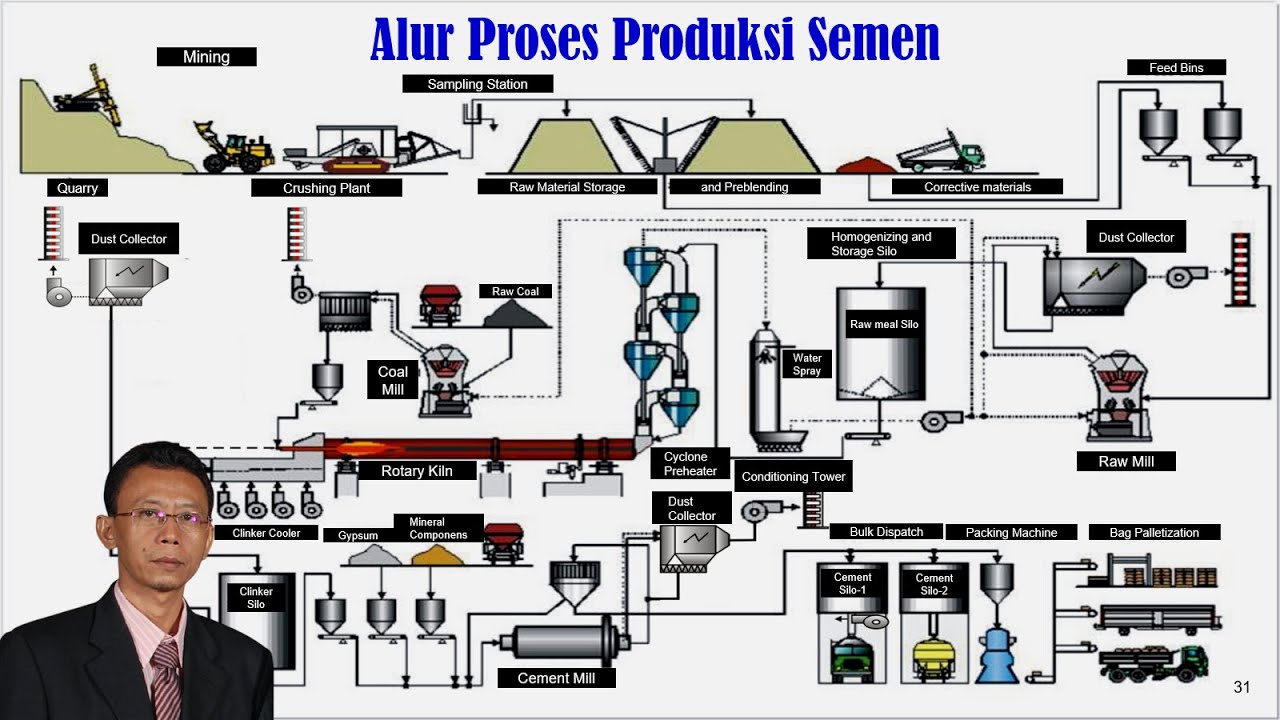

TLDRThis video provides a detailed overview of the cement production process, from raw material extraction to final product. It describes the steps involved in quarrying, crushing, mixing, and grinding materials like limestone, coal, and other additives. The process includes preheating, high-temperature cooking in a rotary kiln, and cooling to produce clinker. The clinker is then finely ground into cement and stored for shipment. Throughout, production is carefully monitored with real-time data analysis to ensure quality control. The video highlights the significance of cement in creating more efficient, sustainable, and comfortable living environments.

Takeaways

- 😀 The raw materials for cement production are extracted from open-pit quarries.

- 😀 Limestone is extracted using electronic blasting and transported by dumpers to the crushing hall.

- 😀 The limestone is crushed to a maximum size of 80mm before being moved to the pre-homogenization hall.

- 😀 In the pre-homogenization process, the material is arranged in superposed horizontal layers and then mixed vertically to ensure uniformity.

- 😀 The raw material is dried and finely ground into powder, which must be preheated to approximately 800°C in a preheater.

- 😀 The material undergoes a high-temperature process in a rotary kiln, reaching 1450°C with flames of around 2000°C.

- 😀 After exiting the kiln, the material, called clinker, is cooled in a cooler before being stored in silos or a covered hall.

- 😀 The cooled clinker is finely ground with additional materials such as ashes from thermal power plants or blast furnace slag to obtain various grades of cement.

- 😀 Different types of cement are stored in silos before being shipped either in bulk or in bags.

- 😀 The production process is continuously monitored in a control room, with real-time data analysis from sensors placed at various points throughout the production stages.

- 😀 Samples of the material are automatically collected and rigorously analyzed during the production process to ensure quality and consistency.

Q & A

What raw materials are required for cement production?

-The raw materials needed for cement production are extracted from open-pit quarries, with limestone being the primary material.

How is the limestone extracted for cement production?

-Limestone is blasted using electronic detonators and then transported by dumper trucks to the crushing hall.

What happens to the limestone after it is crushed?

-After being crushed to a maximum size of 80 mm, the limestone is transported via a conveyor belt to the pre-homogenization hall.

How is the raw material homogenized during the process?

-The material is arranged in horizontal layers and then taken up vertically to ensure a uniform mixture.

What happens to the mixture after homogenization?

-The mixture is dried and finely ground to obtain a powder known as 'flour,' which is preheated to around 800°C in a preheater.

What temperature is required for the material to undergo proper transformation?

-The material is heated to 1450°C in a rotary kiln, with a flame temperature reaching approximately 2000°C.

What happens to the material after it exits the rotary kiln?

-Once the material exits the kiln, it is called clinker, which then passes through a cooler to lower its temperature.

How is clinker processed after cooling?

-After cooling, the clinker is stored in a covered hall or silos, then finely ground in a ball mill, and mixed with additional materials like thermal ash, blast furnace slag, or gypsum to produce cement.

Where are the different types of cement stored before being dispatched?

-The various types of cement are stored in silos before being shipped either in bulk or in bags.

How is the cement production process monitored?

-The production process is continuously monitored in a control room, where data from sensors placed at various stages is analyzed in real-time.

What is the role of automatic sampling in the production process?

-Automatic samples are taken at each stage of the production process and rigorously analyzed to ensure the quality and consistency of the cement.

How does cement production contribute to building a better quality of life?

-Cement, as an economical, high-performance, and innovative material, helps improve living conditions by making environments safer, more beautiful, more comfortable, and more functional.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

Alur Proses Produksi Semen (Tahapan Proses Produksi Semen)_Indonesia

How Cement Is Made In Factories?

Kimia Industri - Diagram Alir Proses Pembuatan Semen

Sering Lihat Tapi Gak Tau Proses Pembentukannya? Begini Cara Pembuatan Semen Dari Awal Hingga Akhir

How Cement is Made? Cement Production Process 🪨

How CEMENT is Made | in FACTORIES

5.0 / 5 (0 votes)