Like Ice Cream! Process of Making Makeup Cushion Foundation. Cosmetic Factory in Korea

Summary

TLDRThis video takes viewers through the meticulous process of cosmetic production, showcasing every step from measuring base raw materials to the final product. Key stages include mixing base and color ingredients, adding secret elements like honey, and ensuring precise consistency with heating and filtering. The process also involves careful molding, freezing, and laser engraving, finishing with the packaging of products like compact powder, blushers, and cushions. The products are then stored and made ready for retail, providing an inside look into the creation of high-quality cosmetics, from start to finish.

Takeaways

- 😀 Precise measurement of base raw materials is done using an electronic scale.

- 😀 Color raw materials are created through kneading and rolling to achieve a dough-like consistency.

- 😀 The color mixture is finely refined to ensure quality and consistency.

- 😀 Secret ingredients, like honey, are added to enhance the product formula.

- 😀 The mixture is heated to 70 degrees to prevent hardening and maintain its texture.

- 😀 Raw materials are filtered through a fine strainer before use to ensure purity.

- 😀 Beige base raw materials are prepared and used in the final product.

- 😀 Molds are heated before being filled with the prepared mixture to ensure proper setting.

- 😀 After filling the molds, the products are hardened in a freezer for a solid finish.

- 😀 Laser engraving is used for precise and quick branding or marking of the products.

- 😀 The surface of the product is cleaned and smoothed evenly using heat for a polished finish.

- 😀 Final products are stored in controlled environments before being sent to retailers like Olive Young.

Q & A

What is the first step in the cosmetics production process?

-The first step is measuring the base raw materials using an electronic scale to ensure the correct amount is used.

How are the base raw materials prepared before moving to the next process?

-Once the base raw materials are measured, they are moved to the next process without further preparation until the color raw materials are ready.

What is the significance of checking the bar code?

-Checking the bar code ensures that the correct ingredients and materials are being used in the production process.

What is the texture of the color raw materials during production?

-The color raw materials are described as having a dough-like consistency, similar to flour dough, which is kneaded and mixed in detail.

How is the color raw material processed after kneading?

-After kneading, the color raw material is mixed again with a roller to achieve the desired texture, which must be done carefully and minutely.

What happens when the color raw material is finished?

-Once the color raw material is completed, it is combined with the base ingredients and secret ingredients are added to enhance the formulation.

What are the secret ingredients added to the mixture?

-One secret ingredient added to the mixture is something like honey, and another secret ingredient is also added to achieve the desired result.

Why is the mixture heated to 70 degrees during production?

-The mixture is heated to 70 degrees to prevent it from hardening prematurely during the process of mixing the base and color ingredients.

What is done if the mixture hardens during production?

-If the mixture hardens, it is melted again and then used in the production process.

How are the final products, like compact powder and blusher, prepared for packaging?

-The products are placed in molds, where they are hardened in a freezer. Afterward, they are placed into cushion cases and engraved with a laser for identification and branding.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

Kimia Industri - Pembuatan Cat (Diagram Alir Proses) (Bag.2 - Akhir)

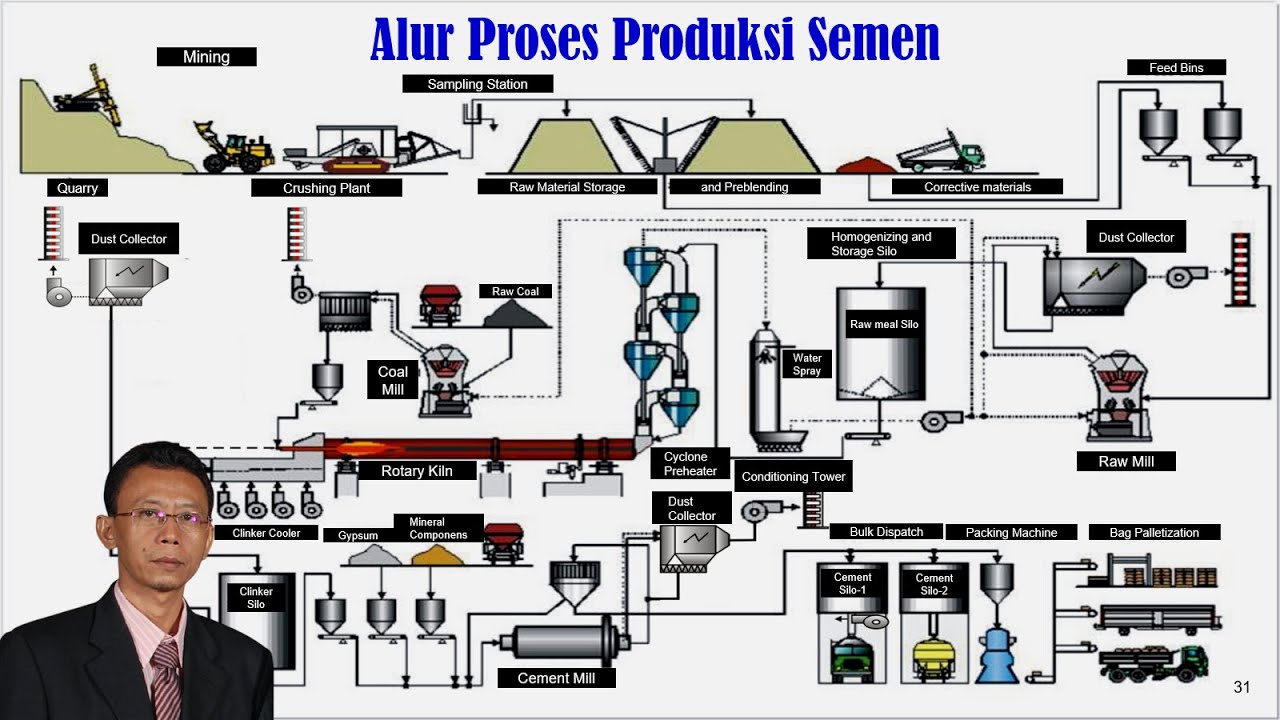

Alur Proses Produksi Semen (Tahapan Proses Produksi Semen)_Indonesia

Como é FABRICADO o PORCELANATO #Boravê 🔵Manual do Mundo

Cara membuat tas ransel dari bungkus kopi part 1

Amazing Modern Ceramic Tile Manufacturing Process With Advance Technology And Creative Workers

PROCESO DE COMPRA DE MATERIA PRIMA

5.0 / 5 (0 votes)