Supply Chain Modelling: Multi Objective Robust Optimization Model for Facility Layout Design

Summary

TLDR在本次供应链建模小组的会议中,来自印尼大学的Gina Natalia Prayago女士介绍了她的论文《多目标鲁棒优化模型在需求不确定性下的设施布局设计》。该研究强调了设施布局规划在制造业中的重要性,指出操作成本的20%至50%依赖于设施规划和物料搬运设计。论文提出了一种新的多目标鲁棒优化模型,考虑了产品需求的不确定性,并通过优化模型来最小化物料搬运成本、最大化总议程和空间利用率。研究使用了离散场景表示需求不确定性,并通过Kuromori优化器和Python进行求解,展示了模型在实际案例中的应用。最后,演讲者提出未来可以开发启发式算法以获得更高效的运行时间和接近最优解的解决方案。

Takeaways

- 📈 多目标鲁棒优化模型被提出用于在需求不确定性下进行设施布局设计。

- 🏭 设施布局规划对制造业成本有显著影响,约占运营成本的20%至50%。

- ⚙️ 考虑需求不确定性的设施布局优化模型目前研究较少。

- 🔍 产品需求的不确定性影响物料流动频率,进而影响部门的有效定位。

- 📏 使用距离公式计算部门间的物理距离,并用以评估部门间的接近度。

- 📊 通过多目标鲁棒优化方法,考虑生产需求的不确定性,最小化物料搬运成本。

- 🎯 三个目标函数:最小化预期总物料搬运成本,最大化总接近度,最大化空间利用率。

- 🛠️ 模型使用离散场景表示需求的不确定性,并通过二进制变量表示部门的方位。

- 📉 模型包括了多种参数,如部门的尺寸、产品需求、搬运成本等,以及它们之间的函数关系。

- 🔢 通过Kuromoji优化器和Python解决模型,得到最优解,包括部门的位置和方向。

- 📚 论文提出了一个精确模型,并建议开发启发式算法以获得更高效的运行时间和近似最优解。

Q & A

什么是设施布局规划在制造业中的重要性?

-设施布局规划是制造业中的一个重要因素,因为它可以影响制造系统中大约20%到50%的运营成本。有效的设施布局设计可以导致操作成本的显著变化,大约在10%到20%之间。

为什么在设施布局规划中考虑需求的不确定性很重要?

-产品需求的不确定性会影响物料流动频率的不确定性,进而影响部门之间有效定位的重要性。因此,考虑需求不确定性的优化模型对于设施布局规划至关重要。

在设施布局设计中,如何计算部门之间的距离?

-在设施布局设计中,使用距离公式来计算部门之间的距离。每个部门都有一个中心点,用Xi和Yi表示,部门之间的距离会影响其功能需求。

在提出的多目标鲁棒优化模型中,有哪些目标函数?

-在提出的多目标鲁棒优化模型中,有三个目标函数:第一是最小化预期的总物料搬运成本;第二是最大化总的接近度;第三是最大化空间利用率。

如何使用离散场景来表示产品需求的不确定性?

-在模型中,使用离散场景来代表产品需求的不确定性。每个场景都与一定的概率相关联,这些概率用于在模型中表述需求的不确定性。

在模型中,如何考虑部门的取向?

-部门的取向通过考虑部门的长度和宽度以及它们相对于x轴的方向来定义。取向影响部门之间的距离,进而影响设施布局规划。

在提出的模型中,如何确保部门的布局既有效又符合空间限制?

-模型通过一系列约束来确保部门布局的有效性和符合空间限制,包括部门的尺寸、部门之间的距离、以及部门在x和y轴方向上的位置。

在模型中,如何考虑物料搬运成本?

-模型中考虑物料搬运成本是通过计算从一个部门到另一个部门搬运单位物料的距离乘以搬运成本来实现的。

在提出的模型中,如何量化部门之间的接近度?

-部门之间的接近度是通过评估部门之间的距离和它们之间的关系来量化的。接近度用一个介于0到5之间的数值来表示,其中5表示最大程度的接近。

在实际应用中,如何使用Kuromobi优化器来解决这个多目标鲁棒优化问题?

-通过将问题输入到Kuromobi优化器中,并使用Python编程语言来求解,可以得到最优解,包括部门的最佳位置和取向。

在演讲中提到的数值例子中,可用区域的尺寸是多少?

-在数值例子中,可用区域的长度是55单位,宽度是40单位。

在演讲中,对于模型的运行时间和效率有什么建议?

-演讲中提到,虽然使用的是精确模型,但为了获得更高效的运行时间和接近最优解,可以开发启发式算法。

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

Webinar - Supply Chain Optimization: A Robust Supply That Minimizes Costs

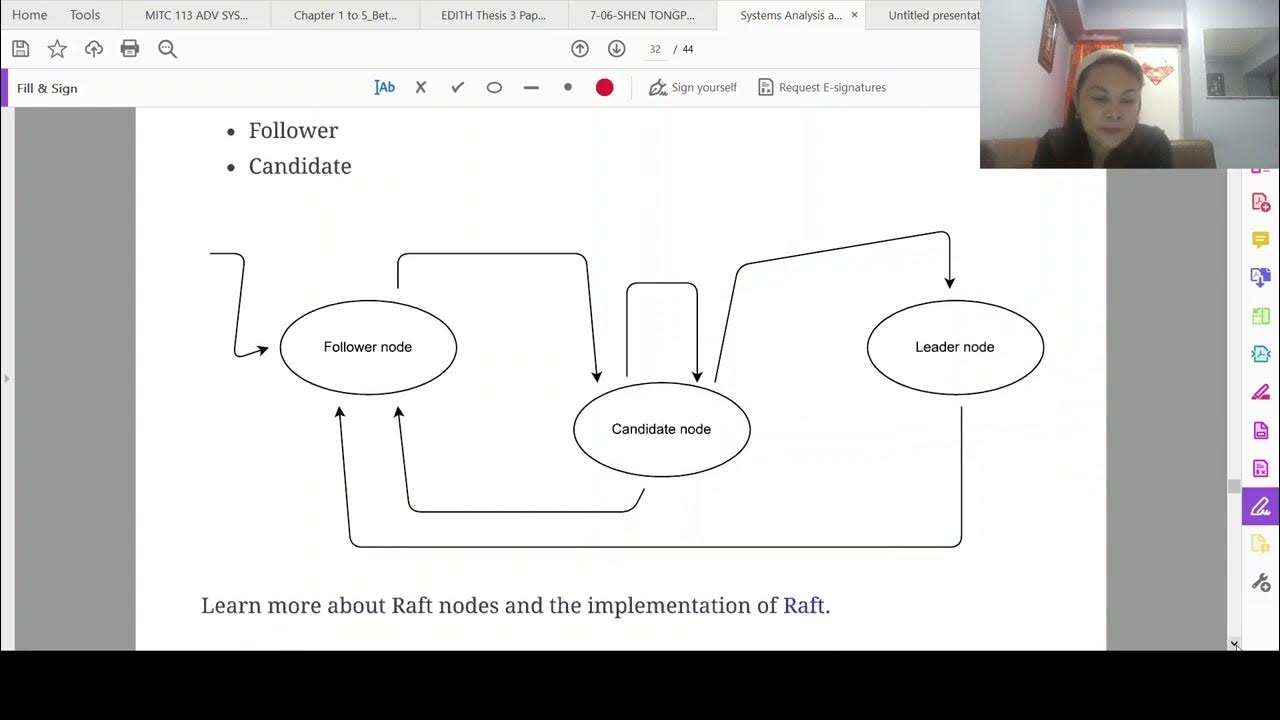

Distributed System Design

Components vs Interfaces vs Abstract Classes (When to Use What?)

一米长的镇宅神物-大冰箱!万代 HGUC GP03D 石斛兰 高达模型介绍【评头论足】

GridFinity Parametric File #freecad #cad #design

Networking for GenAI Training and Inference Clusters | Jongsoo Park & Petr Lapukhov

5.0 / 5 (0 votes)