How To Use Thread Plug Gages Technical Series 101

Summary

TLDRThis video outlines the effective use of go and no-go thread plug gauges for inspecting internal screw threads. It emphasizes the importance of correct specifications, calibration checks, and the cleanliness of workpieces to ensure accurate measurements. Inspectors are advised to handle gauges with care to prevent damage and to utilize the no-go gauge to verify thread tolerances effectively. The video also highlights best practices for maintaining thread plug gauges, including regular cleaning and protective measures, ensuring optimal performance in thread measurement processes.

Takeaways

- 🔧 Go and no-go thread plug gauges are simple and cost-effective tools for inspecting internal screw threads.

- 🛠️ Proper labeling on thread plug gauge handles and gauge members is essential for user clarity.

- 📏 It's crucial to confirm that the correct major diameter, TPI (threads per inch), pitch, and class of fit are specified before using the gauges.

- 🔍 Inspectors should always ensure gauges are calibrated and recheck them prior to use, regardless of calibration status.

- 📅 Calibration frequency should be based on actual usage rather than arbitrary annual schedules to avoid quality issues.

- ✨ A clean and burr-free workpiece is recommended to reduce friction and wear on the gauges.

- 🧼 Thread plug gauges should be cleaned with solvent or air and frequently coated with a rust preventative.

- 🛡️ When not in use, thread plug gauges should be protected in plastic tubes and coated in wax to prevent damage.

- ⚠️ If a gauge is dropped, it should be immediately inspected for damage before further use.

- 🔄 The no-go gauge should only engage the part up to three turns, but limiting it to 1.5 to 2 turns is advisable.

Q & A

What are go and no-go thread plug gauges?

-Go and no-go thread plug gauges are tools used to inspect internal screw threads, helping to determine whether the threads are within specified tolerances.

Why is it important to calibrate thread plug gauges?

-Calibration ensures the accuracy of the gauges. It is important to recheck thread plug gauges prior to use, regardless of their calibration status, to avoid quality issues due to wear or damage.

What should inspectors verify before using a thread plug gauge?

-Inspectors should ensure that the correct major diameter, threads per inch (TPI) or pitch, class of fit, and go/no-go pitch diameters are clearly specified.

How can wear or damage to gauges occur during production?

-Gauges can become worn or damaged due to continuous use in production runs, particularly if they are not checked for wear regularly.

What is the function of the chip groove in AGD thread plug gauges?

-The chip groove in AGD thread plug gauges is designed to clean the threads of the workpiece, although it should not be solely relied upon for cleaning.

How should thread plug gauges be cleaned and maintained?

-Thread plug gauges should be cleaned with solvent or air, frequently recoded with a rust preventative, and protected in plastic tubes coated in wax when not in use.

What is the recommended engagement technique for the go thread plug gauge?

-The go thread plug gauge should engage the internal threaded part with very little force, ensuring smooth engagement without excessive pressure.

What should an inspector do if the go gauge binds during use?

-If the gauge starts to bind, the inspector should stop immediately to avoid damaging the part or the gauge, as this may indicate issues like undersized threads or lead errors.

What is the proper usage limit for the no-go thread plug gauge?

-The no-go thread plug gauge should not enter the part more than three turns; however, it's advisable to limit it to one and a half to two turns maximum for safety.

Why is it essential for the end user to review thread specifications in detail?

-It's crucial for the end user to review thread specifications as variations in no-go gauging practices exist depending on the thread standard, which can affect quality control.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

Power Screws - Torque to Force Relationships in Just Over 10 Minutes!

Java threads 🧵

JAVA TECHNICAL QUESTION & ANSWERS FOR INTERVIEW PART - V ( MULTITHREADING - II )

How does a Deadweight Tester Work? Set-up | Operation | Pressure Flow

How to Use a Tap and Die Set

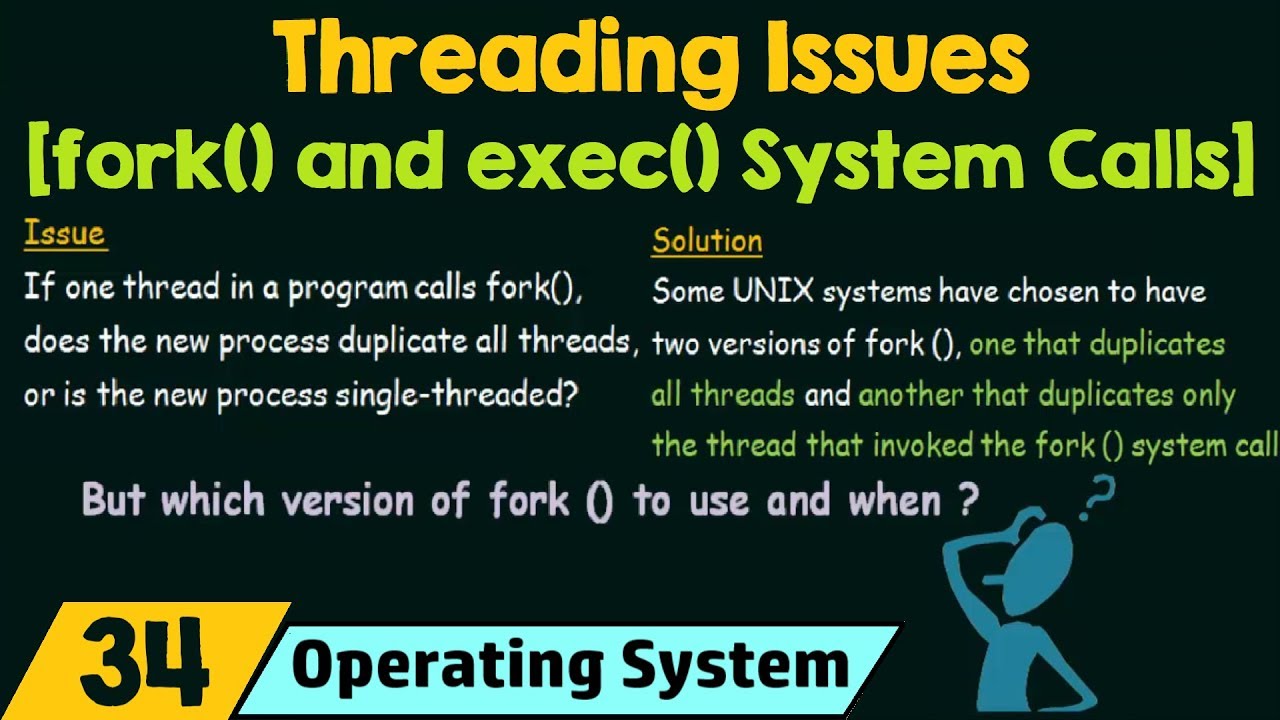

Threading Issues [fork() & exec() System Calls]

5.0 / 5 (0 votes)