How does a Deadweight Tester Work? Set-up | Operation | Pressure Flow

Summary

TLDRThis video script outlines the use and operation of a Budenburg hydraulic deadweight tester and dual range piston cylinder unit for calibrating pressure gauges and transducers. It details the setup, including leveling, filling with mineral oil, and using valves and a screw press to generate precise pressures. The dual range unit's efficiency in calibrating both high and low pressures with a single setup is highlighted, emphasizing the tester's accuracy, reliability, and the availability of technical support and accessories.

Takeaways

- 🔧 Deadweight testers are used to verify the precision of pressure gauges or transducers, with capabilities ranging from 0.01 bar to over 2600 bars.

- 📏 The Budenburg hydraulic deadweight tester and dual range piston cylinder unit are highlighted, emphasizing their setup and operation.

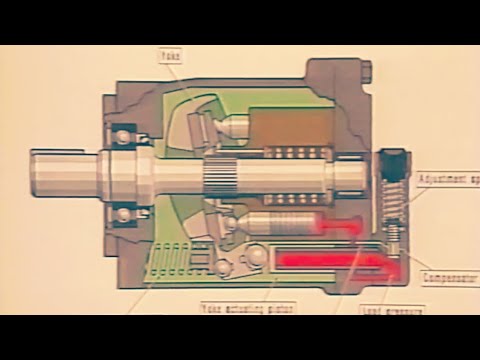

- 🏋️♂️ The tester consists of components such as mass set weights, valves, a reservoir, a gauge to be tested, a piston cylinder unit, a screw press, and leveling feet.

- 🔨 The hydraulic circuit is crucial for transferring liquid within the deadweight tester.

- ⚖️ The piston cylinder unit must be level for accurate readings, using the spirit level and adjusting feet.

- 💧 Mineral oil is used to fill the reservoir, and air must be expelled from the system for accuracy.

- 📡 The hand gauge stand is used to monitor oil levels and prevent overflow.

- 🔄 For calibration, the appropriate gauge or instrument is attached and the screw press is used to generate pressure.

- 🔄 Different valve settings are required for pressures up to and exceeding 140 bar, involving a two-step process with valve A and B.

- 💡 The dual range piston cylinder unit allows for calibration of both high and low pressures with a single unit, saving time and resources.

- 🏅 Budenburg deadweight testers are recognized for their accuracy, reliability, robustness, and longevity, offering primary standard calibration.

- 📚 Technical support and training, as well as a variety of accessories, are available to ensure certified standard calibration.

Q & A

What is the primary purpose of a deadweight tester?

-Deadweight testers are mainly used to test the accuracy of a pressure gauge or pressure transducer.

What is the range of pressures that deadweight testers can handle?

-Pneumatic deadweight testers can handle pressures as low as 0.01 bar, while hydraulic deadweight testers can handle pressures up to 2600 bars.

What are the key features of a Budenburg hydraulic deadweight tester?

-Key features include mass set weights, valves for pressure control, a reservoir for liquid containment, a gauge to be tested, a piston cylinder unit for optimal accuracy, a screw press for generating pressure, and leveling feet.

How do you ensure the piston cylinder unit is level?

-Use the spirit level on the top face of the piston cylinder unit and adjust the four corner feet accordingly.

What is the role of the filler plug and the reservoir in the setup of a deadweight tester?

-The filler plug is removed from the reservoir to fill it with the appropriate mineral oil, and the reservoir is used to contain the liquid during the testing process.

How do you fill the system with mineral oil and remove trapped air?

-Rotate the screw press wheel clockwise to fill the reservoir with oil, then fully rotate the screw press anti-clockwise to draw the oil into the system, and finally rotate it clockwise to expel trapped air.

What is the procedure for calibrating a pressure gauge with a deadweight tester?

-Load the piston cylinder unit with weights that equal the desired pressure, close valve B and leave valve A open for pressures up to 140 bar, then rotate the screw press clockwise to generate pressure. For pressures above 140 bar, follow the same procedure but close valve A and open valve B after the handle becomes stiff.

What is the benefit of using a dual range piston cylinder unit?

-A dual range piston cylinder unit allows for the calibration of both high and low pressure using just one piston unit, saving time and money.

What are the components of a dual range piston cylinder unit?

-The components include the piston head, auxiliary weight, high and low pressure bands, auxiliary piston, vent, and both high and low pressure pistons.

How does the dual range piston cylinder unit operate for different pressure ranges?

-The low pressure piston operates until it reaches equilibrium with the mass set weights and supply pressure. As pressure increases, the high pressure piston operates through the low pressure piston, which now acts as the high pressure cylinder.

What are the unique advantages of using a Budenburg deadweight tester?

-Budenburg testers offer primary standard calibration accuracy, reliability, robustness, longevity, availability of dual range piston cylinder units for wider pressure range calibration, and world-class technical support and training.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade Now5.0 / 5 (0 votes)