How to calibrate RTD temperature transmitters - Beamex

Summary

TLDR本视频由Phoenix BMX和ISA的Michael制作,向观众展示了如何校准RTD温度变送器。首先介绍了两种校准方法,一种是将温度元件连接到变送器并放入加热块中,另一种是通过模拟器模拟电阻变化。视频中详细演示了使用校准器和模拟器进行校准的过程,包括连接测试导线、进行纸面校准、使用通讯器进行传感器调整等步骤。最终,通过精确调整,成功将变送器校准至规格内,并强调了测试设备的准确性和可追溯性的重要性。

Takeaways

- 🔧 校准RTD温度变送器并不困难,有两种主要方法。

- 🌡️ 使用温度元件连接到变送器是常见的校准方法之一。

- 🛁 当无法将探头实际放入温度浴中时,可以通过模拟电阻来校准。

- 📈 通过校准器连接并测量电流,可以观察到4-20mA输出的变化。

- 🔌 四线RTD的连接方式是关键,需要正确连接测试线。

- 📊 使用校准器进行模拟时,可以设置温度范围和校准点。

- 🛠️ 校准过程中可能出现误差,需要通过调整传感器来修正。

- 🔄 进行多点校准时,应确保测试设备准确且可追溯。

- 🔧 使用通讯器进行传感器的精细调整,包括零点和满度调整。

- 📝 校准完成后,应记录校准结果和相关信息。

- 🔄 校准成功后,应断开所有连接并将变送器重新放回系统中。

Q & A

什么是RTD以及它的主要用途是什么?

-RTD是电阻温度检测器(Resistance Temperature Detector)的缩写,主要用于测量温度。它通过检测材料的电阻变化来确定温度,常用于精确温度测量的场合。

在视频中提到的四线RTD是什么意思?

-四线RTD指的是使用四根导线连接的温度传感器,它可以消除导线电阻对测量结果的影响,从而提供更精确的温度读数。

如何将RTD传感器连接到温度变送器?

-将RTD传感器的四根导线分别连接到温度变送器的相应端子上,通常是将两个导线连接到变送器的电源端子,另外两个导线连接到变送器的信号输出端子。

如果不能将RTD传感器实际放入温度校准浴中,有什么替代方案?

-如果不能将RTD传感器放入温度校准浴中,可以使用模拟器来模拟传感器的电阻变化,从而进行校准。

在校准RTD传感器时,为什么不能直接读取0到100摄氏度的范围内的4到20mA输出?

-因为RTD传感器的电阻变化与温度之间的关系是非线性的,所以不能直接将4到20mA输出与0到100摄氏度的温度范围相对应,需要通过校准来建立这种关系。

在校准过程中,如果发现校准失败,应该怎么办?

-如果校准失败,应该检查RTD传感器和温度变送器的连接是否正确,确认使用的校准设备是否准确,并且可能需要重新进行传感器的调整和校准。

如何使用通讯器对RTD传感器进行调整?

-使用通讯器连接到RTD传感器,进入诊断和服务菜单,选择传感器调整选项,按照指示进行两点调整(包括低端和高端),并进行模拟校准信号的输入,以调整传感器的输出。

为什么测试设备需要比被测试单位更精确?

-测试设备需要比被测试单位更精确,以确保测量结果的准确性。通常测试设备的精确度需要是被测试单位的四倍,这样才能检测出被测试单位的误差。

测试设备需要具备哪些特性?

-测试设备需要具备两个关键特性:一是比被测试单位更高的精确度,二是可追溯性,即测试设备需要定期进行校准,以确保其测量结果能够追溯到国家标准。

在校准RTD传感器后,需要做什么来保存校准结果?

-在校准完成后,需要在测试设备上保存校准结果,这通常包括校准的日期、执行校准的人员、校准的参数以及任何相关的校准备注。

完成RTD传感器校准后,下一步应该做什么?

-完成RTD传感器的校准后,应该断开所有连接线,并将传感器重新安装回过程中,确保传感器可以正常工作并提供准确的温度读数。

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

RTD in detail tutorial explaining 2 Wire RTD , 3 Wire RTD and 4 Wire RTD

what Is Instrument Calibration. Instrument Calibrator. RTD Calibration. Calibration certificates.

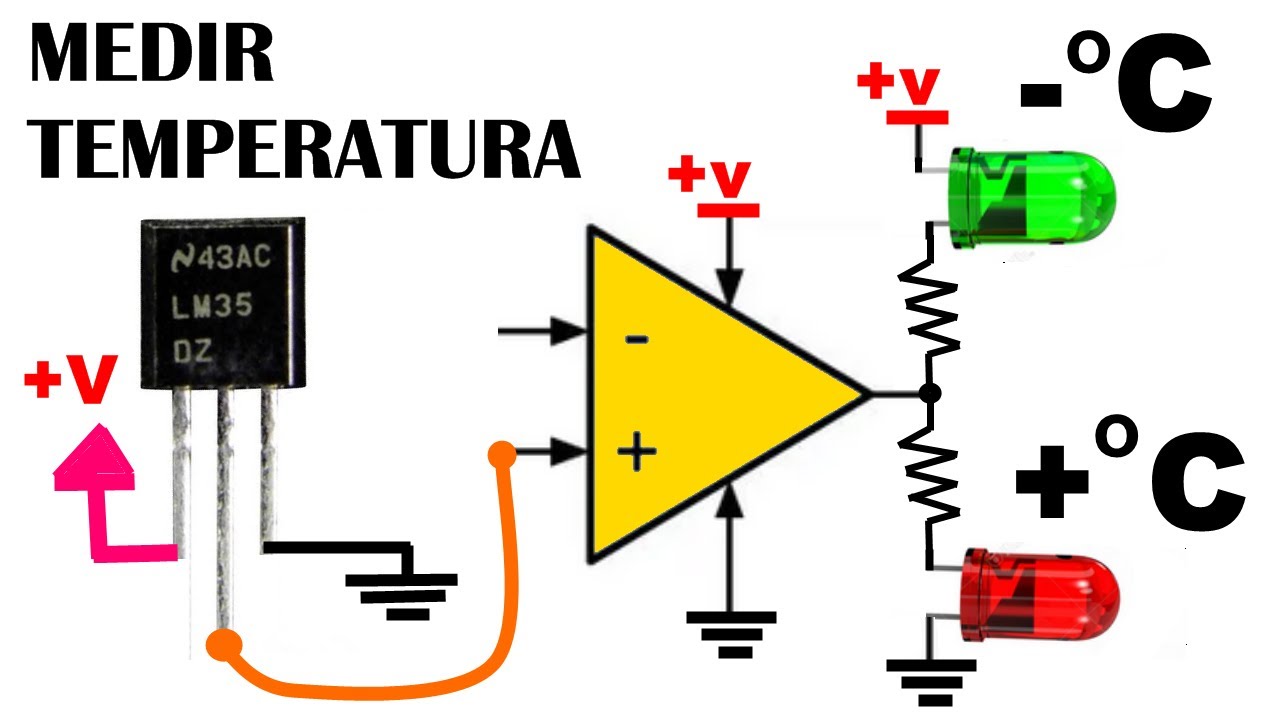

Como medir la temperatura usando el sensor LM35 y un Op-Amp!

Three-Phase Virtual Synchronous Generator (VSG) Double Loop Control In MATLAB/Simulink

fais ATTENTION à ÇA avant d'acheter une LUMIÈRE !

USEFUL Ideas to 3D Print - May 2025

5.0 / 5 (0 votes)