How to make a BUBBLE FREE casting with urethane resin with using a pressure pot; TUTORIAL

Summary

TLDRMarietta's channel presents a bubble-free casting tutorial using urethane resin. Despite initial struggles with moisture and pressure pot issues, she shares valuable lessons on mold preparation, avoiding contamination, and accurate resin mixing. The tutorial emphasizes the importance of following product directions and maintaining pressure throughout the curing process. Viewers are taken on an entertaining and educational journey, concluding with a surprisingly successful casting result.

Takeaways

- 🎨 Marietta introduces a bubble-free casting tutorial using urethane resin.

- 🚫 She shares common mistakes to avoid, emphasizing the importance of following instructions carefully.

- 💧 Moisture is highlighted as a critical factor to control, as it can ruin the clarity of the resin.

- 📦 The tutorial includes steps to ensure a successful cast, starting with mold preparation and avoiding dust or impurities.

- 🌡️ Understanding the exothermic reaction of resin hardening, which causes the material to heat up, is crucial.

- 🔬 Accurate measurement by weight, not volume, is necessary for the correct ratio of resin components.

- 💉 Mixing the resin thoroughly is essential to avoid imperfections in the final product.

- 🌀 The use of a pressure pot is the only way to achieve a bubble-free finish, as it compresses bubbles to an invisible size.

- ⏱️ Maintaining pressure throughout the hardening process is vital to prevent bubbles from reappearing.

- 🔩 The tutorial includes practical demonstrations of measuring, mixing, and using a pressure pot for casting.

- 🛠️ Despite the challenges and potential for error, the end result can be a clear, bubble-free casting, showcasing the artist's perseverance.

Q & A

What is the main topic of Marietta's video?

-Marietta's video is about a bubble-free casting tutorial using urethane resin.

Why did Marietta decide to share her mistakes in the video?

-Marietta shared her mistakes to help viewers avoid making the same errors, as casting with resin can be expensive and time-consuming.

What is the most important factor to consider when working with urethane resin according to the video?

-Moisture is the most important factor to consider when working with urethane resin, as it can cause issues such as cloudiness and bubbles.

What did Marietta do to ensure her mold was properly prepped for casting?

-Marietta used alcohol wipes to clean the mold, ensuring it was free of dust and impurities, and made sure any items placed inside, like flowers, were completely dry.

Why is it crucial to follow the product directions when casting with urethane resin?

-Following the product directions is crucial because urethane resin is sensitive to incorrect measurements, which can affect the curing process and the final product's clarity and strength.

What is the role of a pressure pot in the casting process?

-A pressure pot is used to remove bubbles from the resin by compressing them to a size where they are not visible to the naked eye, ensuring a bubble-free finish.

What should be done if the material starts to harden before it is fully set in the mold?

-If the material starts to harden before it is fully set, it is important to keep the pressure on until the material has fully hardened to prevent bubbles from reappearing.

Why does Marietta recommend starting small when experimenting with casting?

-Marietta recommends starting small to learn the process and avoid wasting materials, as mistakes can lead to imperfections like bubbles or cloudiness in larger projects.

What challenges did Marietta face while using the pressure pot in her video?

-Marietta faced difficulties in pressurizing the pot, dealing with air escaping, and managing the heat generation from the compressor, which made the process exhausting and challenging.

How did Marietta ensure the resin mixture was thoroughly mixed?

-Marietta ensured the resin mixture was thoroughly mixed by stirring carefully and making sure to scratch the bottom of the mixing container to incorporate all components evenly.

What was the final outcome of Marietta's casting attempt shown in the video?

-Despite the struggles, Marietta's final casting turned out to be clear and bubble-free, which she found surprising and satisfying.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

Jewelry Casting with Jamg HE High Wax Plus Resin | Rhino Ring Part 3

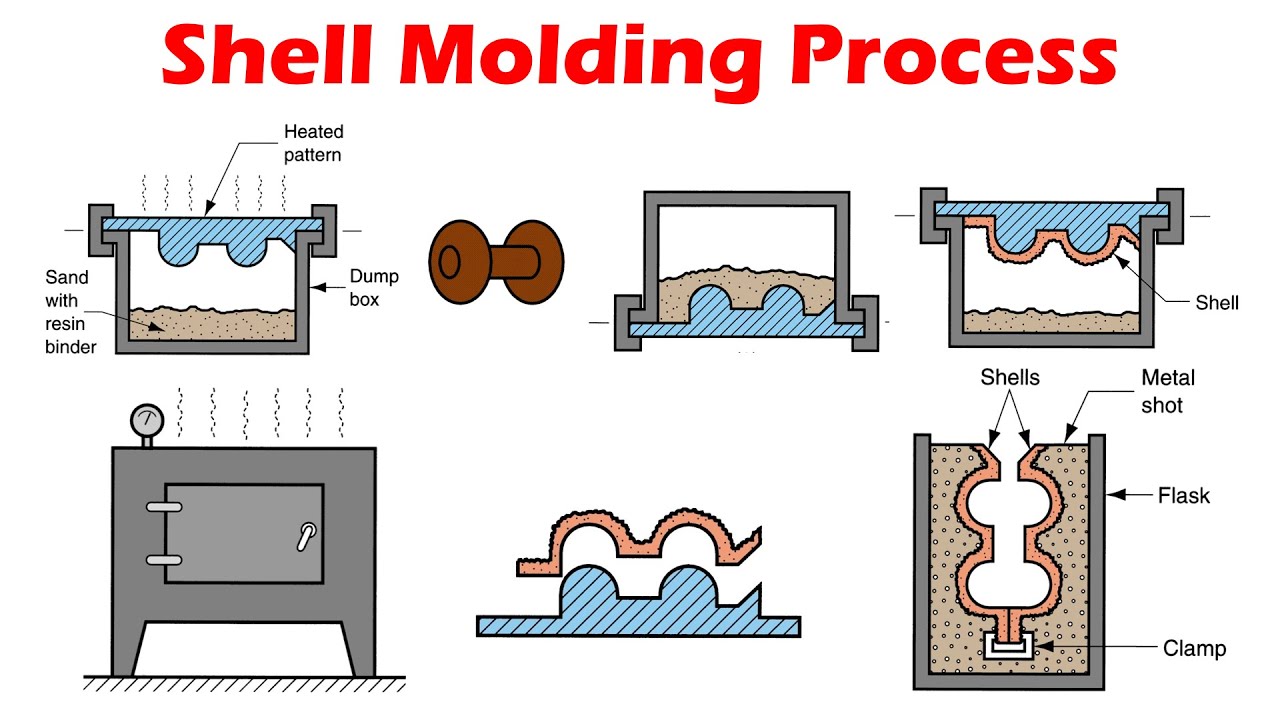

Shell Molding - Expandable Mold Casting Processes

DIY | Casting Vacuum Chamber

Pembuatan produk bahan komposit | Asbak dari resin epoxy dan serbuk kayu

Lost Wax and Lost Resin Casting Burnout Process | How to get good casting results| Casting 3D Prints

MEMBUAT SOUVENIR GANTUNGAN KUNCI RESIN DAN BUNGA KERING

5.0 / 5 (0 votes)