Kimia Industri - Diagram Alir Proses Pembuatan Semen

Summary

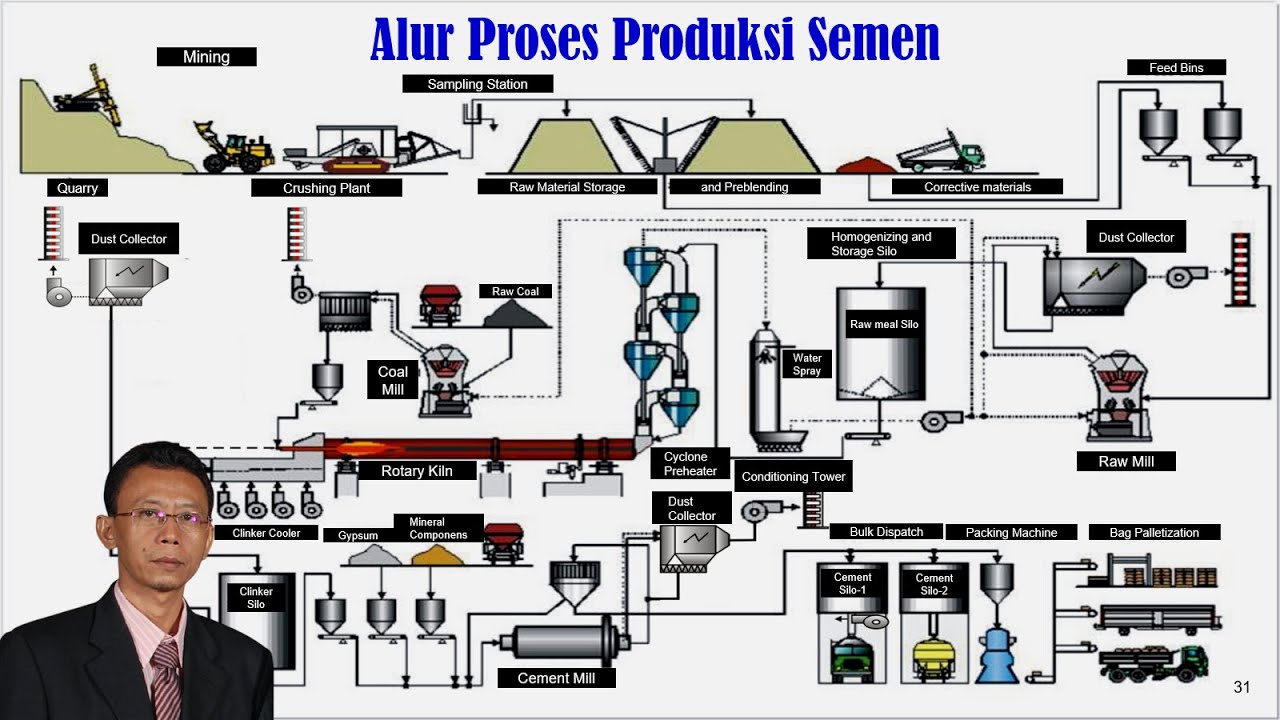

TLDRThis video offers a comprehensive walkthrough of the cement manufacturing process, from the initial extraction of limestone to the final packaging of cement. Key stages include material extraction (stripping, drilling, blasting), crushing, pre-homogenization, grinding, blending, and the crucial kiln process where clinker is formed at extremely high temperatures. The final product is cooled, ground with gypsum, and prepared for distribution. The script breaks down each step with technical precision, providing valuable insights into the complexities of cement production for an engaging and educational viewing experience.

Takeaways

- 😀 The cement production process begins with quarrying, which includes stripping soil to expose limestone, followed by drilling, blasting, and breaking the rock into smaller pieces.

- 😀 After breaking, the limestone is transported to crushers where it is further reduced in size. The crushers include a primary and a secondary gyratory crusher.

- 😀 Pre-homogenizing is done through blending and stacking to ensure that the composition of limestone and clay is uniform before moving to the next stage.

- 😀 Weighing and measuring are crucial steps to ensure accurate proportions of raw materials, including limestone, clay, silica, iron ore, and gypsum, before they enter the grinding stage.

- 😀 Raw materials are then ground in a raw mill, where grinding, drying, and separating occur. The material size is reduced from 700 micrometers to 9 micrometers, and moisture is reduced to 1%.

- 😀 The material undergoes homogenization in a blending silo to ensure uniformity in composition before it moves to the calcination stage.

- 😀 The calcination process occurs in a preheater and a calciner, where calcium carbonate is decomposed into calcium oxide and CO2, essential for clinker formation.

- 😀 The rotary kiln is where clinker formation occurs at temperatures around 1450°C, promoting chemical reactions to form new minerals critical for cement.

- 😀 After clinker formation, it is cooled quickly in a grate cooler, reducing its temperature from 1300°C–1450°C to around 120°C–200°C.

- 😀 Finally, the cooled clinker is ground with gypsum and other additives to produce cement, which is then packaged and distributed for use in construction.

Q & A

What is the first step in the cement production process?

-The first step in the cement production process is the extraction of raw materials, mainly limestone, from mining areas. This is followed by stripping away the overburden to expose the limestone.

Why is the process of drilling and blasting necessary in cement production?

-Drilling and blasting are necessary to break up large rock formations into smaller, more manageable pieces, making them easier to transport and process in later stages of production.

What role does the gyratory crusher play in cement production?

-The gyratory crusher is used to crush the extracted materials into smaller pieces. It helps reduce the size of limestone and clay to a manageable level, making them easier to grind in the raw mill.

How does the pre-homogenization process improve the quality of the final product?

-Pre-homogenization ensures that the materials, especially limestone and clay, are blended to a uniform consistency. This process reduces variability in the raw mix, leading to a more consistent quality of the final cement product.

What is the purpose of the raw mill in cement production?

-The raw mill is used to grind the raw materials into a fine powder. This grinding process is essential for achieving the correct particle size and moisture content needed for subsequent stages in the cement-making process.

What is calcination, and why is it an important step in cement production?

-Calcination is a chemical process that occurs when limestone (calcium carbonate) is heated to high temperatures, breaking it down into calcium oxide (quicklime) and carbon dioxide. This step is crucial because it enables the formation of the necessary chemical compounds for clinker production.

What happens in the rotary kiln during clinker formation?

-In the rotary kiln, raw material undergoes a high-temperature process (around 1450°C) to form clinker. The heat causes chemical reactions that produce new minerals, which are essential for the final cement product.

Why is the clinker rapidly cooled after leaving the rotary kiln?

-The clinker is rapidly cooled to stabilize the newly formed minerals and prevent further chemical reactions. This is done by passing air through the clinker in a grate cooler, reducing its temperature from around 1450°C to about 120-200°C.

What is the purpose of the final grinding stage in cement production?

-The final grinding stage is where the clinker is mixed with gypsum and other additives, then ground into a fine powder. This stage ensures that the cement has the correct particle size and uniformity for proper hydration when mixed with water.

How is cement packaged and distributed after production?

-After production, the cement is either packed into bags or distributed in bulk. The cement is stored in silos before being packed into bags or transported directly to consumers for use in construction projects.

Outlines

Cette section est réservée aux utilisateurs payants. Améliorez votre compte pour accéder à cette section.

Améliorer maintenantMindmap

Cette section est réservée aux utilisateurs payants. Améliorez votre compte pour accéder à cette section.

Améliorer maintenantKeywords

Cette section est réservée aux utilisateurs payants. Améliorez votre compte pour accéder à cette section.

Améliorer maintenantHighlights

Cette section est réservée aux utilisateurs payants. Améliorez votre compte pour accéder à cette section.

Améliorer maintenantTranscripts

Cette section est réservée aux utilisateurs payants. Améliorez votre compte pour accéder à cette section.

Améliorer maintenantVoir Plus de Vidéos Connexes

Alur Proses Produksi Semen (Tahapan Proses Produksi Semen)_Indonesia

How Cement Is Made In Factories?

How Cement is Made? Cement Production Process 🪨

Process de fabrication du ciment - Ciments Calcia

Cement Manufacturing

Sering Lihat Tapi Gak Tau Proses Pembentukannya? Begini Cara Pembuatan Semen Dari Awal Hingga Akhir

5.0 / 5 (0 votes)