Dasar Pemrograman Mesin CNC TU 2A (Absolut dan Inkremental)

Summary

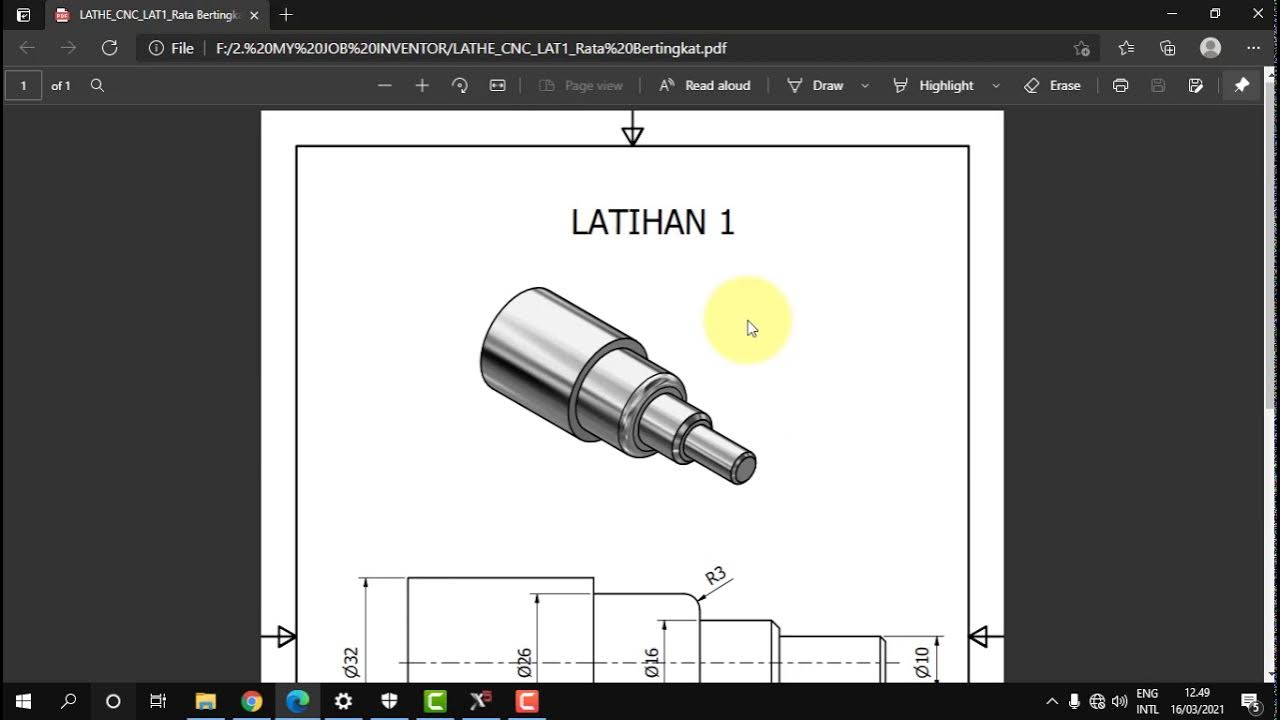

TLDRThis video provides an introduction to CNC turning machines with 2-axis programming, focusing on key concepts such as the basic structure of CNC programs, the function of Zero Offset Points, and the two main programming methods: Absolute and Incremental. The script explains how CNC machines communicate through coded instructions, detailing the three main parts of a CNC program—header, body, and footer. Practical examples of both programming methods are given, with exercises for students to practice. Overall, the content is designed to help beginners understand the fundamentals of CNC programming in an engaging and accessible way.

Takeaways

- 😀 CNC machines require a programming language to communicate commands to the system, which is then processed by a controller and translated into mechanical movements to form the workpiece.

- 😀 A CNC program consists of several blocks of code, with each block containing a set of instructions (or words) that dictate specific actions for the machine to perform.

- 😀 CNC programming is divided into three main parts: the program opening, the body of the program, and the program closing.

- 😀 The opening of a CNC program includes commands like G158 for zero offset and G90/G91 for defining absolute and incremental programming methods.

- 😀 The body of the CNC program defines the actions and movements, such as straight cutting (G01) or circular movements (G02, G03), which shape the workpiece.

- 😀 The program closing part stops the spindle, resets reference points, and ends the program with an M30 command.

- 😀 A 2-axis CNC turning machine has two main axes: the X-axis (cross movement) and the Z-axis (longitudinal movement), each serving a specific direction for machining.

- 😀 Zero offset point adjustment on a CNC lathe determines the starting point for programming, typically at the workpiece's edge, and involves moving only the Z-axis.

- 😀 Two programming methods for CNC are used: Absolute (G90) and Incremental (G91). The Absolute method uses a fixed reference point, while the Incremental method changes the reference point after each movement.

- 😀 In Absolute programming (G90), all coordinates are measured from the same reference point, typically the starting position of the tool.

- 😀 In Incremental programming (G91), the reference point shifts after each movement, meaning each subsequent position is measured relative to the previous one.

Q & A

What is the role of programming languages in CNC machines?

-Programming languages are used to communicate instructions to CNC machines. These languages, like G-codes, allow operators to specify the actions the machine should perform, such as movements or tool changes.

What does a CNC program consist of?

-A CNC program consists of several blocks, each containing a line of code. Each block includes addresses (commands), such as G-codes for machine movements and numerical values that define specific actions or parameters.

What are the three main parts of a CNC program?

-The three main parts of a CNC program are: 1) Program Opening - which initializes the machine settings, 2) Program Body - where the main operations and movements are defined, and 3) Program Closing - which stops the machine and ends the program.

How does the Zero Offset Point function in CNC programming?

-The Zero Offset Point is used to set a reference point (0,0) for the machine to start measurements. This point ensures consistent and accurate positioning of the tool when programming a CNC machine.

What are the two primary axes in a 2-axis CNC turning machine?

-The two primary axes in a 2-axis CNC turning machine are the X-axis (horizontal, left-right movement) and the Z-axis (vertical, up-down movement). These axes define the directions in which the tool can move.

What is the difference between Absolute and Incremental programming methods?

-In Absolute programming (G90), all positions are measured from a fixed origin point. In Incremental programming (G91), each position is referenced relative to the previous one, meaning the reference point shifts dynamically with each movement.

How do the G-codes function in CNC programming?

-G-codes are commands used in CNC programming to instruct the machine to perform specific actions. For example, G00 is used for rapid movement, G01 for linear cutting, G02 for clockwise circular movement, and G03 for counterclockwise circular movement.

Why is the program opening section important in CNC programming?

-The program opening section initializes the machine by setting necessary configurations such as tool selection (T1), defining the programming method (G90 for Absolute or G91 for Incremental), and other important parameters like feed rate (G94) and Zero Offset.

What does the body of a CNC program include?

-The body of a CNC program includes the specific movements and operations the machine will perform, such as cutting actions (e.g., G01 for cutting along a straight path) and other machine operations based on the material and desired output.

What is the function of the program closing section?

-The program closing section contains commands to stop the spindle, return the machine to its reference position, and end the program (M30). It ensures the machine finishes its task safely and prepares for the next operation.

Outlines

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraMindmap

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraKeywords

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraHighlights

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraTranscripts

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraVer Más Videos Relacionados

5.0 / 5 (0 votes)