Introduction to Canned Cycles

Summary

TLDRIn this video, Mark from G Code Cheetah discusses the importance and efficiency of canned cycles in G-code programming. He explains how canned cycles like G81 (drilling), G82 (countersink), and G84 (tapping) simplify and speed up CNC programming by condensing multiple lines of code into a single cycle. The video covers key parameters such as depth, retract height, and feed rate, and emphasizes the benefits of using these cycles to reduce coding time. Mark also highlights machine-specific differences, like incremental vs. absolute movements, offering valuable insights for CNC machinists and those new to G-code programming.

Takeaways

- 😀 Canned cycles simplify G-code programming by automating repetitive tasks, making the code more compact and easier to read.

- 😀 G81 is the basic drilling cycle, used for drilling holes with a defined depth and retract height, followed by the cancellation of the cycle with G80.

- 😀 G82 is used for countersink drilling with a dwell time at the final depth, and dwell time can be customized using the P value.

- 😀 G83 is a peck drilling cycle that breaks down deep drilling into smaller passes using a Q value to control the depth of each pass.

- 😀 G84 is the tapping cycle, where feed rate is adjusted according to the pitch of the tap for accurate thread cutting.

- 😀 G85 and G86 are boring cycles used for larger diameter holes, with slight variations in their behavior depending on the operation.

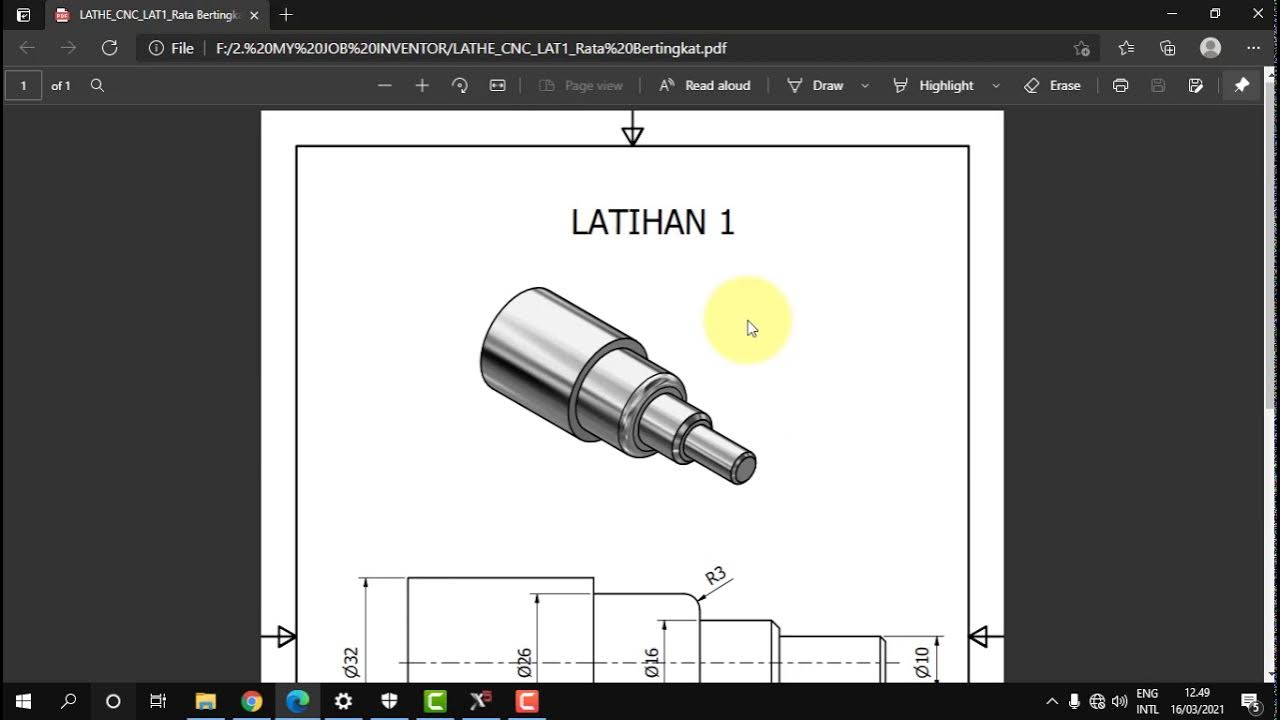

- 😀 Repetitive cycles, like G70 (finishing), G71 (roughing), and G72 (facing), are primarily used for lathe operations, helping remove material efficiently.

- 😀 G91 (incremental positioning) and G90 (absolute positioning) determine how axis movements are interpreted by the machine.

- 😀 Some CNC machines automatically switch to incremental mode when entering a canned cycle, while others may require manual switching using G91.

- 😀 Using canned cycles significantly speeds up programming by reducing the number of lines of code, especially when dealing with multiple features or holes.

- 😀 Cad/Cam software has improved over time to better incorporate canned cycles, reducing the need for lengthy, point-to-point G-code in modern CNC programming.

Q & A

What are canned cycles in CNC programming?

-Canned cycles are predefined sets of G-code commands that simplify repetitive machining tasks like drilling, tapping, and boring. They reduce the amount of code and make programming more efficient and readable.

Why are canned cycles important in G-code programming?

-Canned cycles streamline programming by condensing multiple lines of code into a few commands, which speeds up programming, reduces errors, and enhances the readability of the code.

What is the purpose of the G80 code in canned cycles?

-The G80 code is used to cancel a canned cycle, signaling to the CNC machine that the cycle has been completed and no longer needs to be active.

How do canned cycles like G81, G82, and G83 differ from each other?

-G81 is a basic drilling cycle, G82 adds a dwell time at the bottom of the hole (typically for countersinking), and G83 is used for peck drilling, where the tool makes incremental cuts until the final depth is reached.

What is the difference between absolute and incremental programming in CNC?

-Absolute programming uses fixed reference points (typically the part's datum) for all coordinates, while incremental programming uses the tool's last position as a reference for the next movement, allowing for more efficient relative movements.

How can you ensure that the machine switches to incremental mode when using G81?

-Some machines automatically switch to incremental mode when entering a canned cycle like G81. However, if the machine doesn't do this automatically, you need to manually enter G91 to switch to incremental programming.

What is the role of the 'R' value in a G81 drilling cycle?

-The 'R' value specifies the retract height, which is the distance the tool will retract above the part's datum position after drilling each hole. It ensures that the tool clears the surface before moving to the next position.

Why is it important to adjust the feed rate when tapping with G84?

-When tapping with G84, the feed rate should be set to match the thread pitch of the tap to ensure proper threading. This switches the feed to be per revolution, which is necessary for tapping threads accurately.

What is the significance of using a P-value in a G82 cycle?

-The P-value in a G82 cycle specifies the dwell time at the bottom of the hole, which is useful when performing tasks like countersinking or spot drilling, allowing the tool to pause at the final depth.

How does using CAD/CAM software impact the output of G-code?

-Older CAD/CAM software would often generate lengthy, complex G-code with many point-to-point movements. Modern software has improved and now more effectively utilizes canned cycles, making the generated code more compact and efficient.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

5.0 / 5 (0 votes)