How Vinyl Records Are Made (feat. Third Man Records) | WIRED

Summary

TLDRThis video takes viewers through the intricate process of making vinyl records, starting with cutting the lacquer on a vintage lathe machine, followed by electroplating to create a stamper. The process includes ensuring perfect sound quality, inspecting the vinyl's appearance and audio, and even customizing colors. Special attention is given to factors like temperature, humidity, and cleanliness to avoid defects. After test pressings, the final records are pressed, inspected for audio clarity, and prepared for shipping. Ultimately, the video emphasizes the tactile, emotional experience of listening to vinyl, making it more than just a format—it's an immersive sensory experience.

Takeaways

- 😀 Vinyl record production begins with the cutting of the lacquer, a delicate process using a 1974 VMS70 lathe machine.

- 😀 Lacquer is made from a material similar to nail polish, and it must be kept clean and at a proper temperature during cutting to avoid defects.

- 😀 The cutting process involves precise programming for groove placement and temperature control to ensure optimal sound quality.

- 😀 After cutting, the lacquer undergoes etching, where details such as matrix numbers are added manually.

- 😀 The lacquer is then electroplated to create a stamper, which is a reverse image of the original lacquer for use in mass production.

- 😀 The test pressing phase ensures the sound quality and correctness of the stamper, with careful inspection to avoid issues like rust or dents.

- 😀 Vinyl records are made from polyvinyl chloride (PVC), and the pressing process uses high-pressure steam and precise temperature control.

- 😀 Pressing records involves a quick 45-second cycle, during which a vinyl puck is heated and pressed into a mold before being cooled.

- 😀 Vinyl records can be produced in various colors, but black vinyl is considered to provide the best sound quality due to its manufacturing consistency.

- 😀 The final quality control step checks for audio issues like swishy noise, wavering grooves, or improper fill in the stamper grooves.

- 😀 Once approved, records are labeled, packed, and prepared for shipping, ensuring a high-quality product for vinyl enthusiasts.

Q & A

What is the first step in the vinyl record-making process?

-The first step is cutting the lacquer. This is done with a lathe machine, and the lacquer is similar to nail polish but not fully hardened.

Why is the temperature so important when cutting a lacquer?

-Temperature affects the cutting process. If it’s too hot, it can burn the lacquer and create noise. If it’s too cold, the stylus can’t cut through the lacquer effectively, also causing noise.

What is the role of the lathe machine in vinyl production?

-The lathe machine cuts the lacquer, creating grooves that will eventually carry the sound. The machine’s stylus precisely carves the grooves based on the programmed settings.

How does the machine know how to cut the grooves on a vinyl record?

-The machine's programmer holds all the details necessary for cutting the grooves, such as where the song starts, where the run-out groove goes, and how the grooves should be spaced.

What is a matrix number, and why is it important?

-A matrix number is a unique identifier etched into the lacquer to track the record. It's important for referencing specific pressings of a record.

How is the lacquer preserved during the cutting process?

-The lacquer is kept clean during the cutting process using nitrogen, and the stylus is cleaned with methyl ethyl ketone to avoid contaminants like dust or oils that could affect the sound.

What happens after the lacquer is cut and etched?

-After the lacquer is cut and etched, it undergoes electroplating to create a stamper. The stamper is a reverse image of the lacquer and is used to create vinyl pressings.

What is the electroplating process, and why is it necessary?

-Electroplating covers the lacquer with silver nitrate and dips it into a nickel bath, creating a stamper. This step is necessary to create a durable mold for mass production of vinyl records.

What is the purpose of test pressings in vinyl production?

-Test pressings are made to ensure the audio quality is up to standard. They allow for a thorough inspection before going into mass production.

How does the pressing process work?

-In the pressing process, vinyl grade PVC is placed in the press, heated to 300 degrees, and pressed under high pressure. The vinyl is then cooled, and any excess material is trimmed off.

Why do different vinyl colors require different temperatures during pressing?

-Different colors of PVC melt at different temperatures. Softer colors like orange or clear require cooler temperatures, while black vinyl is generally pressed at higher temperatures for better sound quality.

What are common issues checked during audio quality control?

-During audio quality control, common issues checked include swishy noise, stitching (missing grooves), and wavering of the stylus, which can affect the sound. If any of these issues are detected, adjustments are made to the press.

How does the vinyl’s physical form affect its sound quality?

-The physical form of the vinyl, including how the grooves are cut and how the vinyl is pressed, significantly impacts sound quality. Imperfections such as wavering or incomplete grooves can distort the sound.

Why is black vinyl considered the best for sound quality?

-Black vinyl is considered the best for sound quality because it is the most stable in terms of temperature and press consistency, and the material used tends to provide the clearest audio.

What happens after the final quality check of the pressed vinyl?

-After passing the final quality check, the vinyl is placed on a spindle to flatten, then labeled, packed, and prepared for shipping to consumers.

Outlines

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraMindmap

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraKeywords

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraHighlights

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraTranscripts

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraVer Más Videos Relacionados

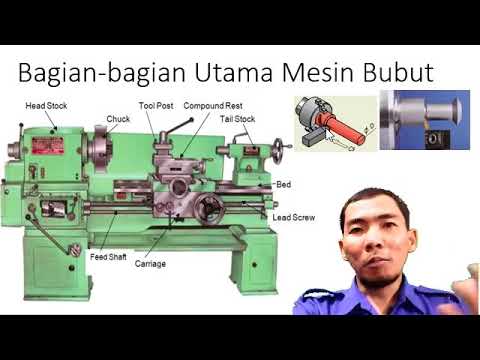

MENGENAL BAGIAN MESIN BUBUT

Latihan Soal Teknik Mesin/Pemesinan #mesin bubut

How to make Custom Holographic Trading Cards using Cricut Explore 3

SERING PAKE, TAPI GAK TAU PROSESNYA? TERNYATA BEGINI TAHAP PEMBUATAN KERTAS DARI AWAL HINGGA AKHIR

Bagian - bagian utama Mesin Bubut

Cara mengoperasikan mesin bubut. (Tehnik dasar)||How to operate a lathe. (Basic technique)

5.0 / 5 (0 votes)