CNC External thread cutting programming using code G76

Summary

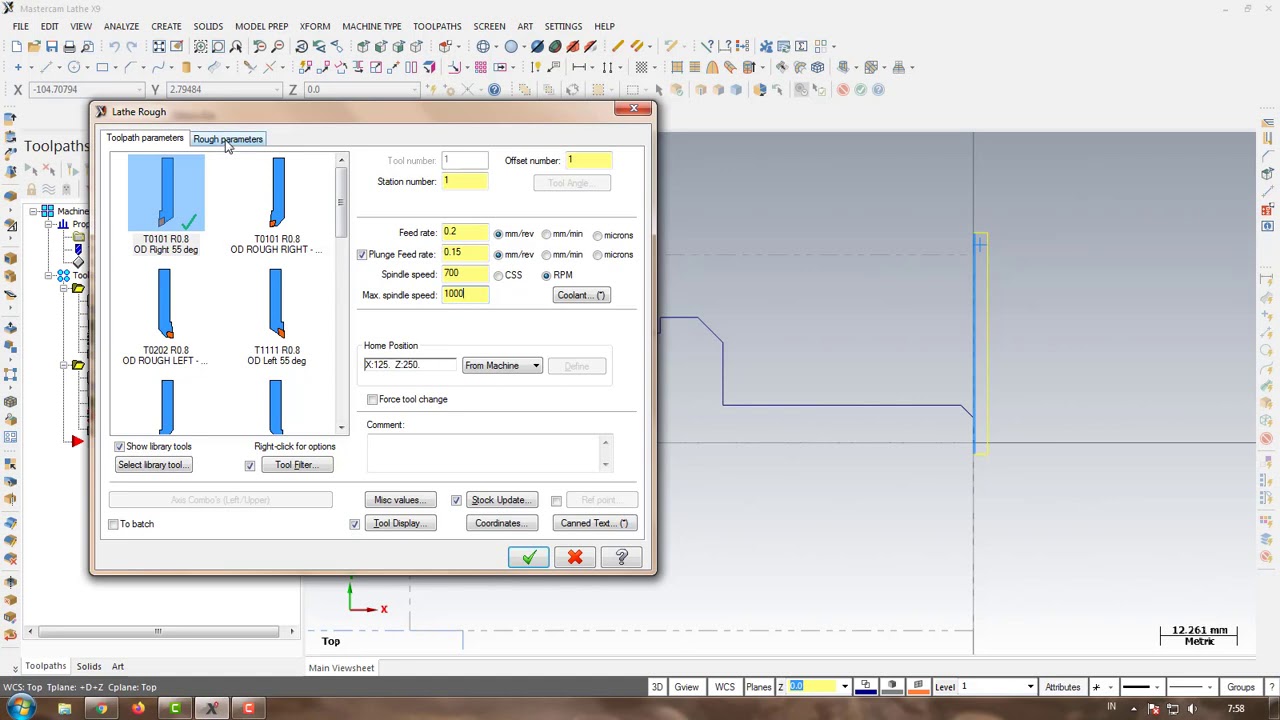

TLDRIn this video, viewers are introduced to programming a CNC turning machine using the G76 code for external and internal cutting. The presenter outlines the key parameters, including dimensions and settings for various cutting tools. Emphasizing the importance of proper programming techniques, the video covers essential concepts such as minimum depth of cut and tool angles. With detailed explanations and practical tips, the content aims to help both beginners and experienced machinists understand the intricacies of CNC programming, ensuring efficient and accurate machining processes.

Takeaways

- 😀 The G76 code is essential for performing both external and internal cuts in CNC turning machines.

- 🛠️ A sample workpiece measuring 50 meters with specific dimensions is discussed as part of the machining process.

- 📏 The script emphasizes the importance of understanding cutting tools and their angles for effective machining.

- 📐 Minimum settings, such as the 150 mm cutting length, are highlighted for programming accuracy.

- 🔄 The use of tool identification numbers is crucial for maintaining consistency in programming.

- ⚙️ Key calculations for tool positioning and the significance of setup parameters are explained.

- 📝 The video discusses how to program multi-start threads, which are vital for specific machining tasks.

- 🔍 The importance of monitoring cutting speeds and feed rates is emphasized for optimal performance.

- ⏳ A reminder to regularly subscribe and stay updated with further machining tips and tutorials is included.

- 🌟 The content aims to simplify complex CNC programming concepts for learners, making it accessible for beginners.

Q & A

What is the main topic discussed in the video?

-The video focuses on writing a problem statement for CNC turning machines, specifically using the G76 code for external and internal cutting.

What materials are specified for the cutting task?

-The cutting task involves a material of 30 * 1.5 100MB metric, with an external diameter of 1325 mm and a length of 50 meters.

What is the purpose of the G76 code mentioned in the transcript?

-The G76 code is used for performing multi-start threading operations and both external and internal cutting on CNC machines.

How long is the expected cutting length?

-The expected cutting length is 50 meters.

What is the significance of the angle of 20 degrees mentioned?

-The angle of 20 degrees is crucial for the correct setup of the cutting tool and its positioning during the machining process.

What factors are considered when calculating the settings for the CNC program?

-Factors such as the number of cuts, the material's characteristics, tool specifications, and the required precision are considered when calculating the settings.

What does the term 'minimum development' refer to in the context of this video?

-Minimum development refers to the least amount of material that needs to be removed to achieve the desired final dimensions in the machining process.

What role does the cutting tool's position play in the CNC programming?

-The cutting tool's position is essential for ensuring accurate cuts and maintaining the integrity of the workpiece during machining.

What does the speaker imply by stating 'keep in mind the sequence numbers'?

-The sequence numbers are important for identifying and organizing the machining steps in the CNC program, ensuring efficient operation.

What final advice does the speaker offer regarding the programming of the CNC machine?

-The speaker emphasizes the importance of thoroughly understanding the G76 code and its parameters to write effective CNC programs.

Outlines

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraMindmap

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraKeywords

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraHighlights

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraTranscripts

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraVer Más Videos Relacionados

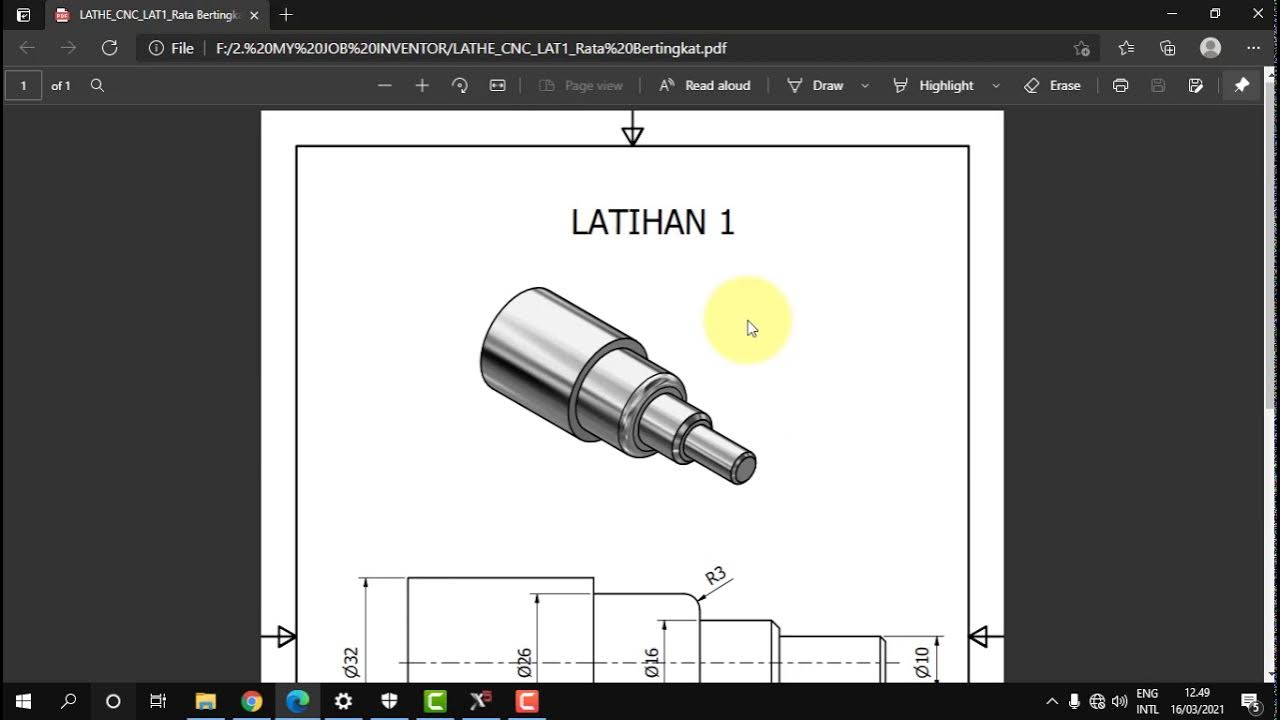

MASTERCAM X5_BUBUT DASAR BIDANG BERTINGKAT

Introduction to Canned Cycles

Turning operation in CREO manufacturing with generating NC part programme

Dasar Pemrograman Mesin CNC TU 2A (Absolut dan Inkremental)

membuat program sederhana CNC Milling

Program CNC Turning Menggunakan MasterCAM X9 (Pembuatan PIN)

5.0 / 5 (0 votes)