Manufacturing of a Fiberboard

Summary

TLDRThis video provides an overview of the process for manufacturing fiberboard at a laboratory scale prior to industrial production. It details the stages including debarking, splitting, and screening of wood, followed by chip washing, pre-steaming, and refining. Adhesives and additives are applied to fibers before they are dried, pressed, and shaped into fiberboards. The process includes both continuous blowline gluing and smaller-scale blending for testing recipes and settings. The result is a fiberboard product with properties similar to industrial-scale production, which can be further processed through sanding or coating before final use.

Takeaways

- 😀 The laboratory scale manufacturing process for fiberboard involves multiple stages, starting with debarking, splitting, and chipping of roundwood.

- 😀 After the wood chips are screened, fine and coarse materials are separated for further processing.

- 😀 The chips are washed, pre-steamed, and compressed to remove excess water before being boiled at around 175°C.

- 😀 The steamed wood chips are refined in a refiner, where they are broken down into fibers.

- 😀 After refining, adhesive and additives are sprayed onto the fibers in the blow line, where they reach supersonic speed.

- 😀 The glued fibers are dried in a flash dryer using an air stream for moisture removal.

- 😀 An alternative method of processing involves mixing fibers with adhesive and additives in a blender, which is ideal for smaller quantities and lab-scale tests.

- 😀 The required amount of fiber for panel production is calculated based on the dimensions and density of the panel after conducting a kiln drying test.

- 😀 The fiber mat is manually spread and pre-pressed to remove air before the hot pressing process, ensuring better heating and stability.

- 😀 The final hot pressing process produces a finished fiberboard with properties comparable to those produced on an industrial scale, followed by cooling, conditioning, and optional further processing like sanding or coating.

Q & A

What is the first step in the fiberboard manufacturing process?

-The first step involves debarking, splitting, and chipping the roundwood, followed by screening to separate fine and coarse materials.

Why is the material screened after chipping?

-The screening process separates fine and coarse materials, ensuring that only the useful fraction of the wood chips is processed further.

What happens to the wood chips after they are washed?

-After washing, the wood chips are pre-steamed and then compressed to remove excess water before being processed in the next stages.

At what temperature are the chips boiled during the refining process?

-The wood chips are boiled in steam at approximately 175°C during the refining process.

What role does the refiner play in the fiberboard production process?

-The refiner uses grinding discs to break down the wood chips into fibers, which are then processed further.

How are adhesives applied to the fibers?

-Adhesives and additives are sprayed onto the fibers in the blow line, where the fibers reach supersonic speeds.

What is the function of the flash dryer in fiberboard production?

-The flash dryer dries the fibers by using an air flow, reducing their moisture content before they proceed to the next step.

What is an alternative to continuous blowline gluing in fiberboard production?

-Instead of continuous blowline gluing, fibers can be mixed with adhesive and additives in a blender, which is especially useful for small-scale lab testing.

How is the required amount of fiber determined for panel production?

-The amount of fiber required is determined by the panel's dimensions and density, and the fiber moisture is measured after a kiln drying test.

What is the purpose of pre-pressing the fiber mat before hot pressing?

-Pre-pressing removes air from the fiber mat, ensuring faster and more thorough heating during the subsequent hot pressing process.

Outlines

Dieser Bereich ist nur für Premium-Benutzer verfügbar. Bitte führen Sie ein Upgrade durch, um auf diesen Abschnitt zuzugreifen.

Upgrade durchführenMindmap

Dieser Bereich ist nur für Premium-Benutzer verfügbar. Bitte führen Sie ein Upgrade durch, um auf diesen Abschnitt zuzugreifen.

Upgrade durchführenKeywords

Dieser Bereich ist nur für Premium-Benutzer verfügbar. Bitte führen Sie ein Upgrade durch, um auf diesen Abschnitt zuzugreifen.

Upgrade durchführenHighlights

Dieser Bereich ist nur für Premium-Benutzer verfügbar. Bitte führen Sie ein Upgrade durch, um auf diesen Abschnitt zuzugreifen.

Upgrade durchführenTranscripts

Dieser Bereich ist nur für Premium-Benutzer verfügbar. Bitte führen Sie ein Upgrade durch, um auf diesen Abschnitt zuzugreifen.

Upgrade durchführenWeitere ähnliche Videos ansehen

Manufacturing of a Particleboard

How Things Are Made | An Animated Introduction to Manufacturing Processes

What is Chemical Engineering?

MRP Basics & Your First Manufacturing Order | Odoo MRP

PEMBUATAN AMONIA || HABER-BOSCH PROCES

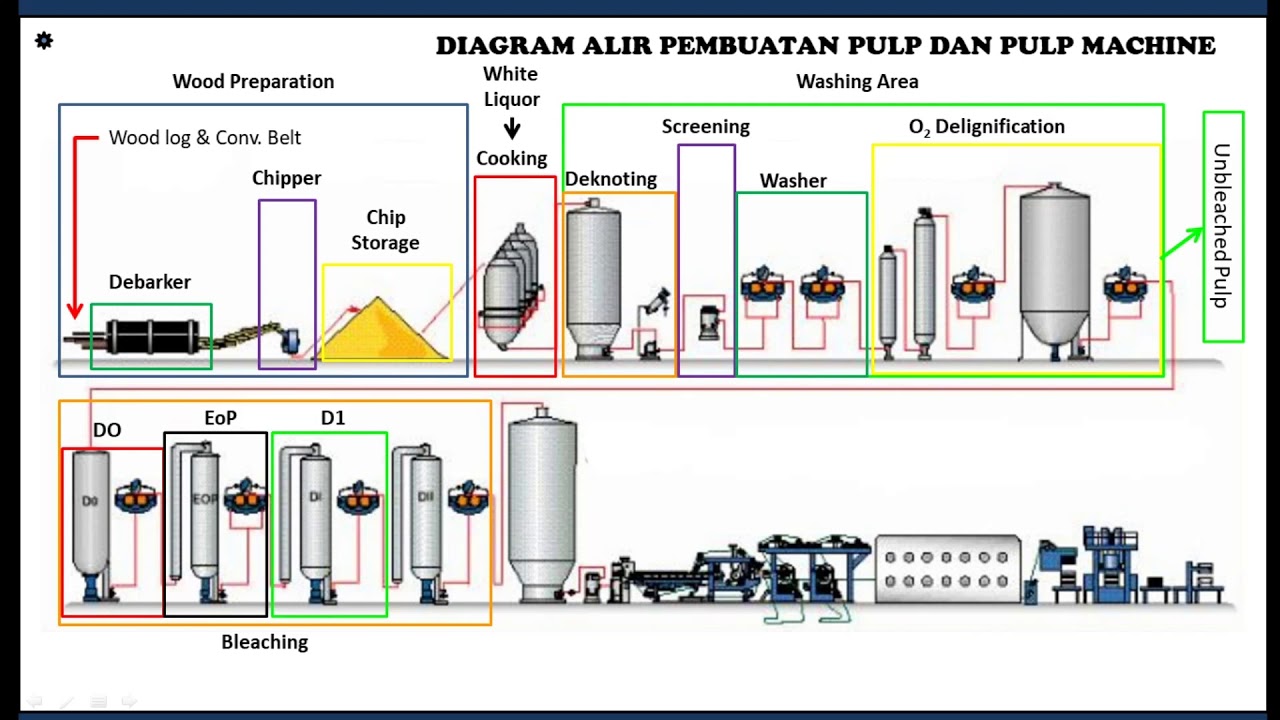

Kimia Industri - Pembuatan Pulp dan Kertas (Diagram Alir proses) (Bag. 2 - Akhir)

5.0 / 5 (0 votes)