Nozioni base sui PLC ( Controllore Logico Programmabile)

Summary

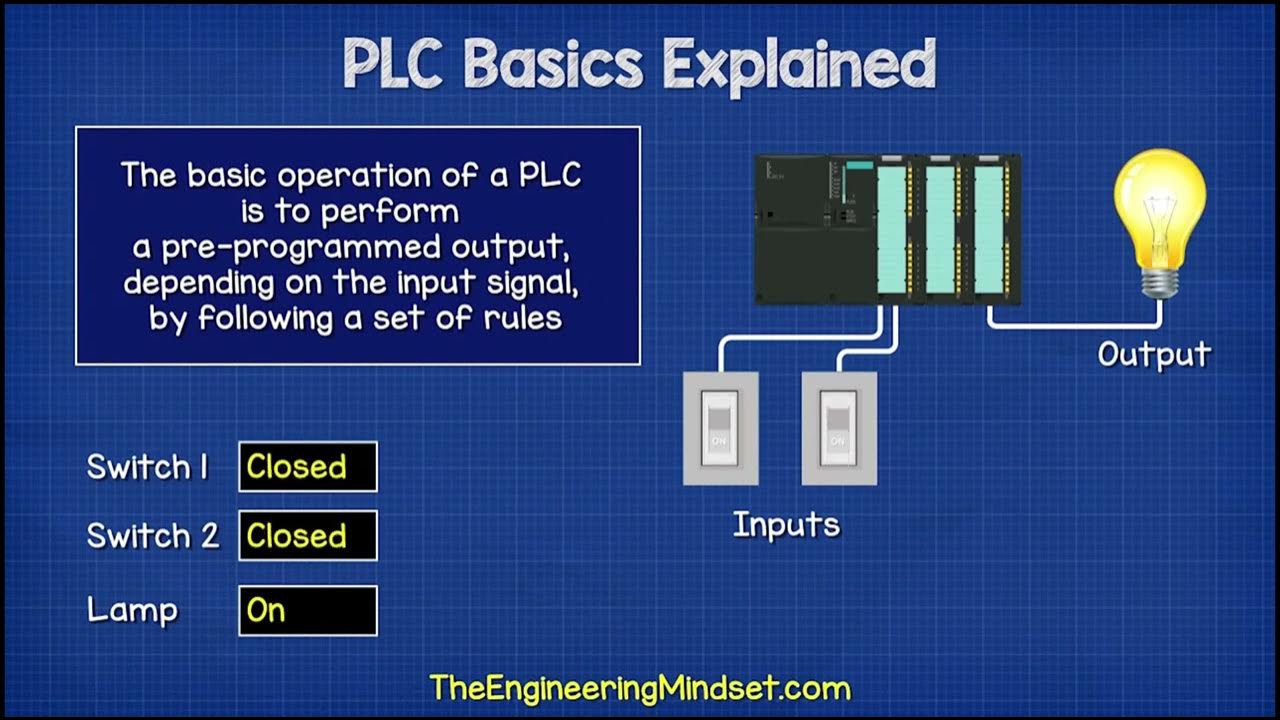

TLDRThe video offers an introduction to Programmable Logic Controllers (PLCs), key devices in industrial automation. It explains how PLCs manage inputs, process them using pre-installed programs, and generate outputs to control machinery. The advantages of PLCs include cost-effectiveness, compact size, low power consumption, reliability, and ease of modification. PLCs also perform well in harsh environments and offer centralized control of production lines. The script covers input devices (sensors, switches) and output devices (motors, relays) that interact with PLCs in automated processes.

Takeaways

- 🤖 PLC (Programmable Logic Controller) is widely used in industrial automation and bridges electromechanical technology of the 70s with modern electronic implementations.

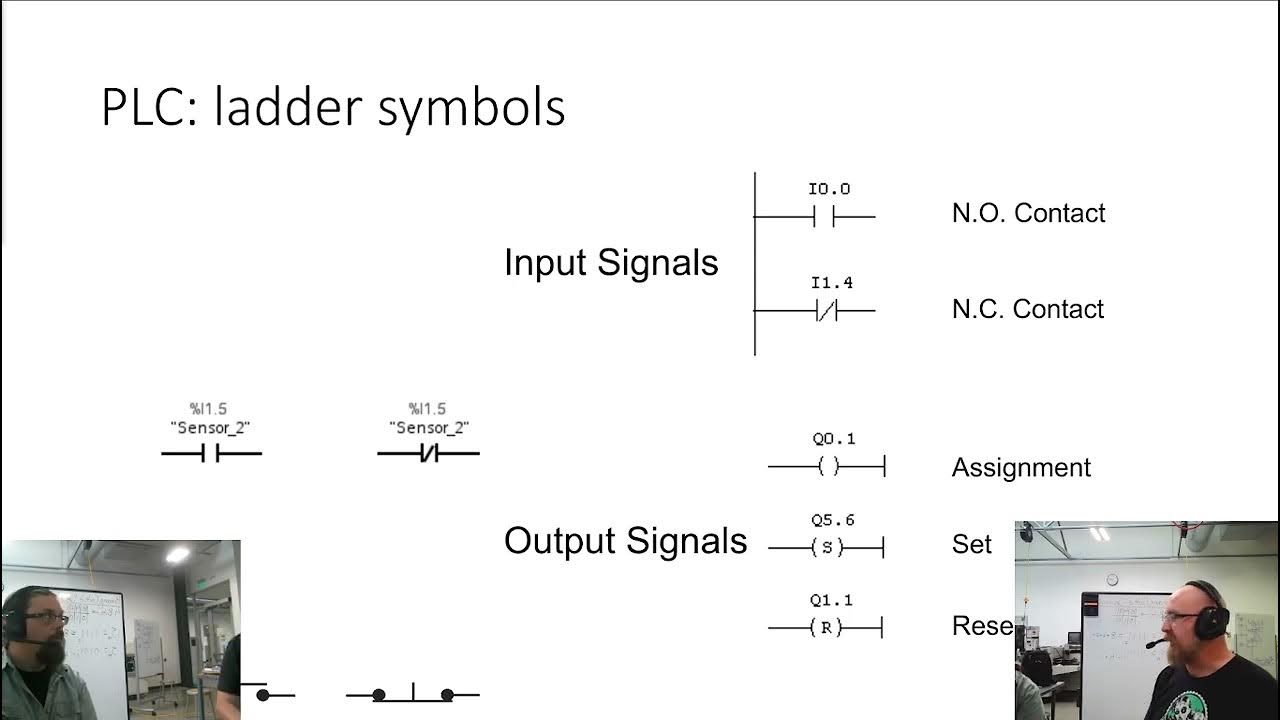

- 🔌 The PLC consists of both hardware and software, allowing it to store programs and manage signals through inputs and outputs.

- 📥 The main function of the PLC is to manage signals: reading inputs, processing them based on the program, and controlling outputs like actuators, relays, and lamps.

- ⚙️ PLCs are at the core of automation, especially in repetitive tasks like those in assembly lines, offering more flexibility than old electrical panels.

- 💡 Key advantages of PLCs include cost efficiency, compact size, low power consumption, high reliability, safety (due to lower operating voltages), and minimal maintenance.

- 🔄 PLCs are easily modifiable, allowing changes to the production process without needing to dismantle the entire system, unlike wired logic setups.

- 🛠️ PLCs can operate in harsh environments with electrical noise, vibrations, temperature fluctuations, and unstable power supplies.

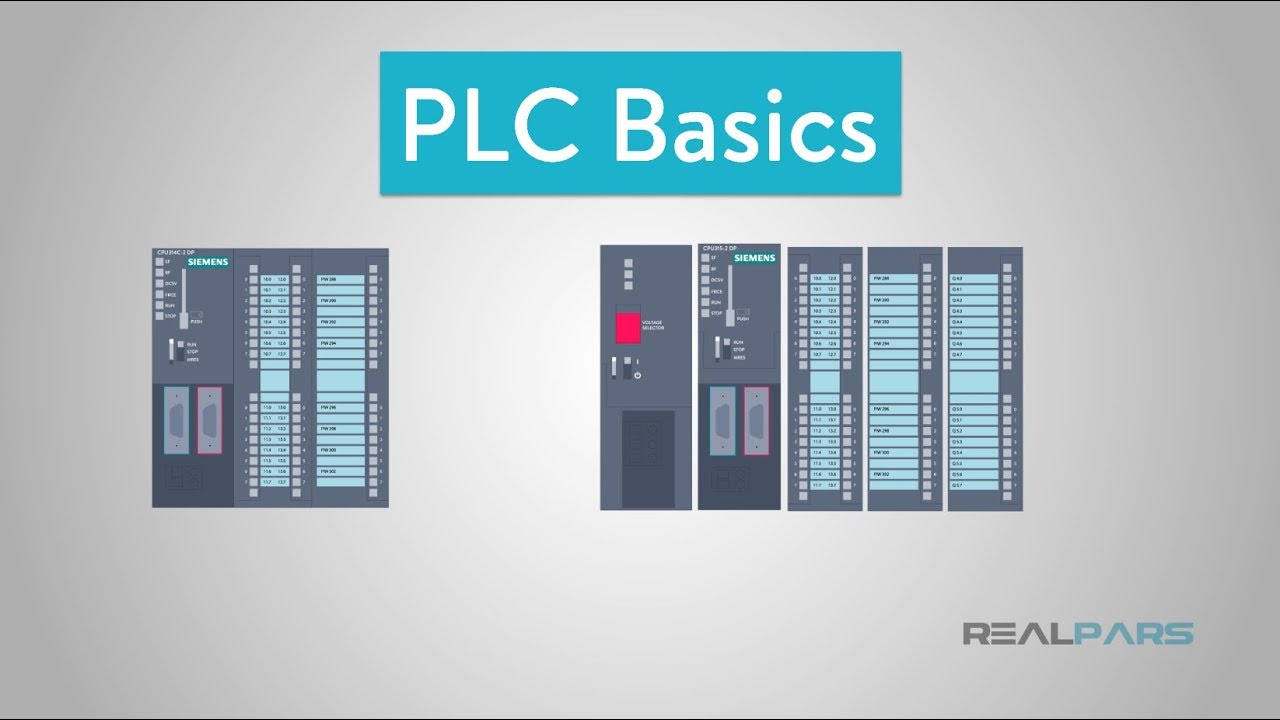

- 💾 Internally, a PLC consists of a CPU, memory for data and program storage, and an I/O system to manage external inputs and outputs.

- 🔄 The PLC operates cyclically, reading inputs, executing the program, and updating outputs in sync with the system’s operations.

- 📊 Inputs and outputs in a PLC can be either analog or digital, allowing the system to interface with a wide range of sensors, actuators, and other devices in an industrial setup.

Q & A

What is a PLC?

-A PLC, or Programmable Logic Controller, is a device widely used in industrial automation. It's a bridge between electromechanical technology used in the 1970s and modern electronic software implementation, featuring both hardware and software components.

What is the main function of a PLC?

-The primary function of a PLC is to manage signals, processing inputs from its inputs and then sending out signals from its outputs to control actuators, relays, lights, and machinery involved in production processes.

What are the advantages of using a PLC over traditional hard-wired logic?

-PLCs offer numerous advantages such as cost-effectiveness, compactness, low power consumption, high reliability, increased safety due to lower voltages, reduced maintenance, easy modifiability, and the ability to be repurposed for other functions.

How is a PLC different from traditional electrical control panels?

-PLCs are more advanced compared to old wired logic panels, offering programmability, compactness, and the ability to work in environments with electrical disturbances, vibrations, high temperatures, and dust.

What does a PLC's internal structure consist of?

-A PLC's internal structure includes a central unit with a CPU, memory for data, program memory, and a power supply. It also has input/output units for external communication.

How does a PLC operate?

-A PLC operates in a cyclical scanning mode, going through steps such as reading inputs, executing the program, waiting, updating outputs, and then dedicating time to the network before repeating the cycle.

What types of devices are used for PLC inputs?

-Standard input devices for PLCs can include command switches, buttons, limit switches, proximity sensors, photoelectric sensors, and rotary encoders.

What are the standard output devices for PLCs?

-Standard output devices for PLCs include relays, timers, counters, temperature controllers, and servomotors.

What is the role of sensors and actuators in relation to PLCs?

-Sensors detect physical quantities for measurement, while actuators convert electrical signals into physical actions, such as movement. They are integral to the input and output operations of a PLC.

How does a PLC handle different types of signals?

-PLCs can handle both analog and digital signals, allowing them to interface with a wide range of sensors and actuators.

What is the significance of the diagnostic capabilities in a PLC?

-Diagnostic capabilities in a PLC allow for self-checking and interfacing with software for remote monitoring and control, enhancing the reliability and efficiency of industrial processes.

Outlines

Dieser Bereich ist nur für Premium-Benutzer verfügbar. Bitte führen Sie ein Upgrade durch, um auf diesen Abschnitt zuzugreifen.

Upgrade durchführenMindmap

Dieser Bereich ist nur für Premium-Benutzer verfügbar. Bitte führen Sie ein Upgrade durch, um auf diesen Abschnitt zuzugreifen.

Upgrade durchführenKeywords

Dieser Bereich ist nur für Premium-Benutzer verfügbar. Bitte führen Sie ein Upgrade durch, um auf diesen Abschnitt zuzugreifen.

Upgrade durchführenHighlights

Dieser Bereich ist nur für Premium-Benutzer verfügbar. Bitte führen Sie ein Upgrade durch, um auf diesen Abschnitt zuzugreifen.

Upgrade durchführenTranscripts

Dieser Bereich ist nur für Premium-Benutzer verfügbar. Bitte führen Sie ein Upgrade durch, um auf diesen Abschnitt zuzugreifen.

Upgrade durchführenWeitere ähnliche Videos ansehen

5.0 / 5 (0 votes)