chocolate temp

Summary

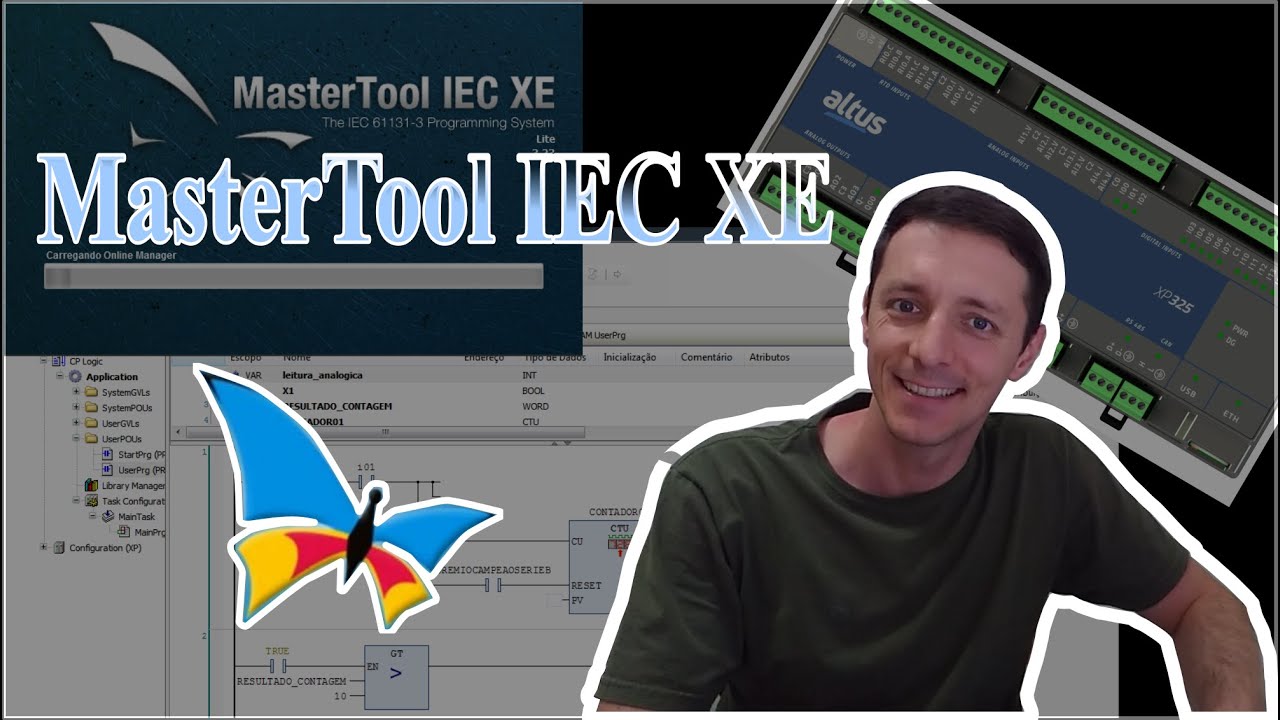

TLDRIn this video, the speaker demonstrates how to set up and program an analog input (temperature sensor) in a PLC to control a chocolate mixing process. The system includes heating and cooling valves to maintain the chocolate temperature between 60-70°C. Using a mix of digital and analog inputs, the speaker creates tags for the temperature sensor, valves, and mixer, and then programs the logic to activate the valves based on temperature conditions. The session ends with a challenge for viewers to identify a potential issue with the program, setting the stage for the next lesson.

Takeaways

- 😀 The script outlines a PLC programming exercise for controlling a chocolate tank's temperature and mixing process.

- 😀 An analog input (chalk temp) is used to measure the temperature of the chocolate in the tank.

- 😀 Two digital outputs control the heating and cooling valves, while a third output controls the mixer.

- 😀 Digital inputs are used for starting and stopping the mixing process (start mix and stop mix).

- 😀 The PLC's IO manager simulates both analog and digital inputs but cannot use them simultaneously on the same terminal.

- 😀 When the temperature goes below 60°, the heating valve is turned on to warm the chocolate.

- 😀 When the temperature exceeds 70°, the cooling valve is activated to cool the chocolate.

- 😀 Between 60° and 70° (the dead band), both valves remain off, ensuring the chocolate stays within the ideal temperature range.

- 😀 Ladder logic programming is used to control the mixer and valves based on the temperature inputs.

- 😀 The script advises checking the comparison functions for errors, specifically focusing on the temperature thresholds and valve control logic.

Q & A

What is the purpose of the analog input in the script?

-The analog input in the script represents a temperature sensor. It is used to monitor the temperature of the chocolate in the tank, which is crucial for controlling the heating and cooling process.

How does the system control the temperature of the chocolate in the tank?

-The system controls the temperature by using two valves: a heating valve and a cooling valve. The heating valve is activated when the temperature drops below 60°C, and the cooling valve is activated when the temperature exceeds 70°C.

What are the tags created for controlling the system?

-The script creates several tags: 'chalk temp' for the temperature sensor (analog input), 'cool' for the cooling valve (digital output), 'heat' for the heating valve (digital output), and 'mixer' for the mixing motor (digital output).

Why can't digital and analog inputs share the same address in the simulator?

-In the simulator, digital and analog inputs cannot share the same address because the analog input occupies the address space. In real-world systems, analog and digital inputs typically use separate terminals, but in this simulation, they use the same space.

What logic is used to control the mixer in the system?

-The mixer is controlled by two digital inputs: 'start mix' and 'stop mix'. When the 'start mix' input is activated, the mixer starts; when the 'stop mix' input is activated, the mixer stops. The mixer also has a holding rung to maintain its state once it starts.

What is the temperature range considered ideal for mixing chocolate?

-The ideal temperature range for mixing chocolate is between 60°C and 70°C. The system ensures that the chocolate stays within this range to avoid solidification (if too cold) or burning (if too hot).

How is the 'less than' comparison function used in the script?

-The 'less than' comparison function is used to activate the heating valve when the temperature falls below 60°C. This ensures that the chocolate is heated when it becomes too cold.

What is the purpose of the 'greater than' comparison function?

-The 'greater than' comparison function is used to activate the cooling valve when the temperature exceeds 70°C. This helps prevent the chocolate from overheating and burning.

What are the possible issues with the current program as indicated in the transcript?

-The transcript hints at potential issues with the numbers used in the comparison functions, though it does not specify the exact problem. The issue could relate to incorrect temperature thresholds or improper configuration of the compare functions.

What should be done before continuing with the next lesson, according to the script?

-Before continuing with the next lesson, the script suggests that the viewer write down what they think might be wrong with the program. The instructor encourages a discussion of the findings in the next lesson.

Outlines

此内容仅限付费用户访问。 请升级后访问。

立即升级Mindmap

此内容仅限付费用户访问。 请升级后访问。

立即升级Keywords

此内容仅限付费用户访问。 请升级后访问。

立即升级Highlights

此内容仅限付费用户访问。 请升级后访问。

立即升级Transcripts

此内容仅限付费用户访问。 请升级后访问。

立即升级5.0 / 5 (0 votes)