Metal Lathe Tutorial 21 : Speeds & Feeds

Summary

TLDRIn this informative episode of 'Lathe Skills', Quinn delves into the complexities of 'speeds and feeds' in machining, debunking common misconceptions and guiding hobbyists through the process of determining optimal cutting parameters. He emphasizes the importance of surface speed, explains the limitations of generic charts, and provides a step-by-step method to calculate spindle RPM and feed rates tailored to individual machines. Quinn also demonstrates the impact of various speeds and feeds on surface finish, encouraging viewers to experiment within safe limits for better machining results.

Takeaways

- 📚 Speeds and feeds is a complex topic with nuances that can be overwhelming for beginners, often leading to a search for simplified guides or charts.

- 🔍 The script emphasizes the importance of understanding where speeds and feeds numbers come from, rather than just using them without context.

- 📐 Surface speed is a fundamental property in machining, and while units may vary, the goal is to determine the appropriate spindle RPM for the task.

- 📊 Common charts for surface speed are often based on unspoken assumptions and may not be accurate for all machining setups, especially for hobbyist machines.

- 🛠️ The Machinery's Handbook provides detailed tables for calculating speeds and feeds, but they are calibrated for professional settings with more aggressive cutting parameters.

- 🔨 There are two main approaches to calculating speeds and feeds: the correct, detailed method involving depth of cut, feed rate, and surface speed calculations, and the more common shortcut method often used by hobbyists.

- ⚙️ Depth of cut is a critical factor influenced by machine rigidity, setup, and urgency of the task, with different materials like aluminum, brass, and steel requiring different approaches.

- 🔄 Feed rate is determined by the machine's capabilities and is often limited by the number of change gear options available on hobbyist lathes.

- 🌀 The relationship between spindle RPM and feed rate is crucial as they both contribute to the final surface speed, affecting the quality of the cut.

- 🛑 The script advises against using aggressive cutting parameters from professional guides on hobbyist machines, as they can lead to machine damage.

- 🔬 The process of determining optimal speeds and feeds involves a balance of factors including material removal rate, machine power, and desired surface finish quality.

- 🔄 Experimenting with different speeds, feeds, and tool nose radii can yield a range of surface finishes, from rough to mirror-like, depending on the setup and material.

Q & A

What is the main topic of the video 'Blondie Axe - Lathe Skills' episode 21?

-The main topic of the video is 'Speeds and Feeds,' which is a critical aspect of machining that the host, Quinn, explains in detail.

Why does the host mention that speeds and feeds is a complicated topic?

-The host mentions that speeds and feeds is complicated because it involves many variables and nuances, which is why there aren't many quick summaries or straightforward guides available.

What is the fundamental property that the host is focusing on in the context of machining?

-The fundamental property the host focuses on is surface speed, which is measured in surface feet per minute (SFM) in the Imperial system.

Why does the host say that the units for surface speed don't matter in the end?

-The host says the units don't matter because the ultimate goal is to determine the spindle RPM, which can be derived from various units of surface speed regardless of what they are.

What is the common mistake the host points out regarding the use of charts for surface speed?

-The common mistake is that these charts often have unspoken assumptions about cutting conditions, and they are usually calibrated for professional settings with more aggressive numbers that may not be suitable for hobbyist machines.

How does the host describe the correct way to calculate speeds and feeds?

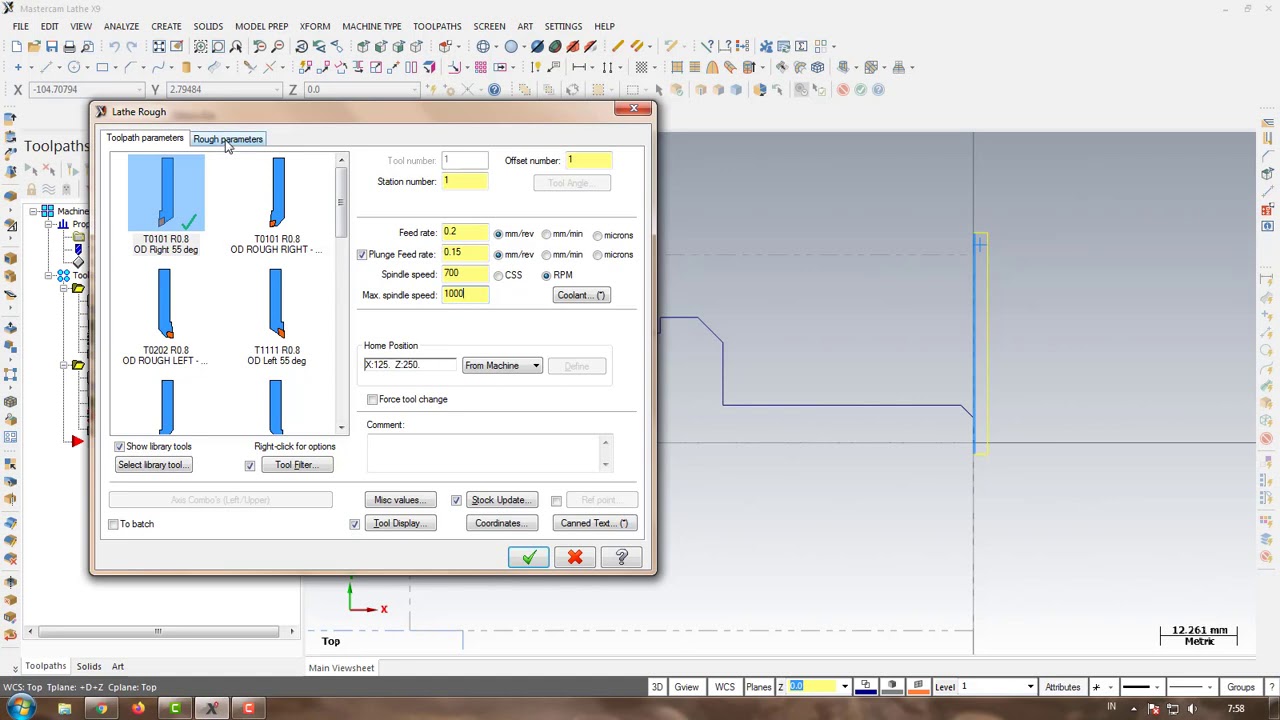

-The host describes a three-step process: 1) Select the depth of cut, 2) Figure out the feed rate, and 3) Convert the derived surface speed into spindle RPM.

What is the significance of the nose radius of the cutting tool in relation to the feed rate?

-The nose radius of the cutting tool is significant because it affects the surface finish. The host suggests that the feed rate should be less than half the radius on the nose of the tool to ensure the best possible surface finish.

What does the host mean by 'the correct way' and 'the way that everybody, especially hobbyists, tend to actually do it' when referring to calculating speeds and feeds?

-The 'correct way' refers to the detailed three-step process involving depth of cut, feed rate, and spindle RPM calculation. The 'way that everybody tends to do it' likely refers to using simplified shortcuts or charts without considering the nuances of their own specific machining setup.

How does the host demonstrate the effect of different speeds and feeds on the machined surface?

-The host demonstrates this by machining parts at various speeds and feeds, showing the resulting surface finishes and explaining the relationship between the chosen parameters and the outcome.

What is the importance of the surface speed in tool wear according to the host?

-According to the host, surface speed is an extremely important factor in tool wear, especially in a production CNC shop, and it has a significant impact on tool life, which is why it is extensively covered in the Machinery's Handbook.

How does the host suggest hobbyists approach calculating feed speed on a mill, given the limitations of their equipment?

-The host suggests that hobbyists map the feed speed to the power feed control knob by zeroing out the hand wheel, accounting for backlash, and timing how far the power feed moves the workpiece over a fixed amount of time.

What is the host's advice for hobbyists who want to understand their machine's capabilities better?

-The host advises hobbyists to go through the calibration process he described to determine the upper bounds of speed and feed for their particular machine and then adjust based on their comfort level.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

5.0 / 5 (0 votes)