Aprendendo a tira esquema de motor elétrico

Summary

TLDRThis video provides a detailed, step-by-step guide on how to rewind a single-phase electric motor, focusing on crucial aspects like measuring coil dimensions, recording motor data (power, voltage, amperage), and understanding wiring connections. The process includes counting coil turns, selecting the correct wire gauge (18 AWG), and ensuring proper capacitor and auxiliary coil connections. The tutorial is aimed at viewers with a basic understanding of motor rewinding, offering technical insights into material choices (copper vs aluminum) and detailed wiring diagrams to ensure proper motor function after rewinding.

Takeaways

- 😀 The video focuses on the process of rewinding a single-phase induction motor and a water pump.

- 😀 It starts with writing down important motor specifications like power, voltage, amperage, and model information.

- 😀 The motor's physical dimensions, such as length (100 mm) and width (75 mm), are noted before proceeding with disassembly.

- 😀 The process of measuring the step of the coil, or how many turns exist between different legs of the coils, is explained.

- 😀 Diagrams and markings on the board are crucial for motor rewinding, ensuring correct connections and avoiding mistakes during assembly.

- 😀 The two primary coils and two secondary coils (auxiliary coils) in the motor are marked for proper identification during rewinding.

- 😀 When measuring coil turns, it’s important to count the turns step-by-step and note the wire type, with aluminum wire being the common material.

- 😀 The secondary coils are connected in series and have specific turn counts (e.g., 6, 8, 10, and 12) with wire choices like 18 AWG aluminum.

- 😀 Accurate drawing of the coil connections is crucial to ensure proper wiring during the rewinding process, avoiding confusion when connecting wires.

- 😀 The video concludes by reinforcing that whether using aluminum or copper wire, the key is to maintain consistency in wire size and ensure a proper connection for smooth motor functionality.

Q & A

What is the purpose of rewinding the electric motor in this video?

-The purpose of rewinding the electric motor is to restore its functionality after it has burned out. This process involves disassembling the motor, measuring its components, and then rewinding the coils to restore them to their original state.

What are the key specifications of the single-phase induction motor being rewound?

-The motor is a single-phase induction motor, model 56 J, with a power of 1.5 HP, voltage of 127/220 V, and an RPM of 3530. The motor uses an electrolytic capacitor (600-540 µF at 127V) and has an amperage of 24A at 127V and 10A at 220V.

Why is it important to draw the motor’s connection diagram before starting the rewinding process?

-Drawing the motor’s connection diagram is crucial to ensure proper rewiring. It helps to avoid confusion during the rewinding process and ensures the motor operates correctly after reassembly by marking where each wire should be connected.

How do you measure the pass of the coils in the motor?

-The pass of the coils is measured by counting the turns from one coil to another. This is done by measuring the distance from one leg of the coil to the next and counting each leg as it is passed, which helps identify how the wire is wound in each coil.

What is the significance of the term 'pass' in motor rewinding?

-The term 'pass' refers to the number of turns the wire makes as it is wound around the coil. Each pass represents a specific number of coils or wire turns, which is important for maintaining the motor's original specifications during the rewinding process.

Why are the two secondary coils connected in series, and how does this affect the rewinding process?

-The two secondary coils are connected in series to form the auxiliary starting coils. This configuration is important for the motor’s startup function. During rewinding, both coils must be rewound with the correct number of turns and properly connected to ensure proper motor operation.

How do you prevent short circuits when rewinding the motor?

-To prevent short circuits, it is essential to draw the motor’s wiring connections clearly and mark where the wires will be connected. Proper insulation and correct leg positioning are also crucial to avoid accidental contacts between the wires.

What is the preferred wire type for rewinding the motor, and why?

-The preferred wire types are either aluminum or copper, with aluminum being more flexible and easier to work with. Copper is also suitable but can be more difficult to wind due to its stiffness. In the video, the motor originally uses aluminum wire.

What should be done after measuring and marking the coil connections?

-After measuring and marking the coil connections, the next step is to cut the coils, count the turns of wire, and measure the wire thickness. This ensures that the motor will be rewound correctly and that the new coils will meet the necessary specifications.

Why is it important to measure the wire thickness (AWG) when rewinding a motor?

-Measuring the wire thickness (AWG) is important because it affects the motor’s electrical properties and performance. Using the correct wire gauge ensures that the motor operates efficiently, with the proper resistance and current capacity, preventing overheating or inefficient operation.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

Cara Kontrol On/Off Motor Listrik dengan Kontaktor

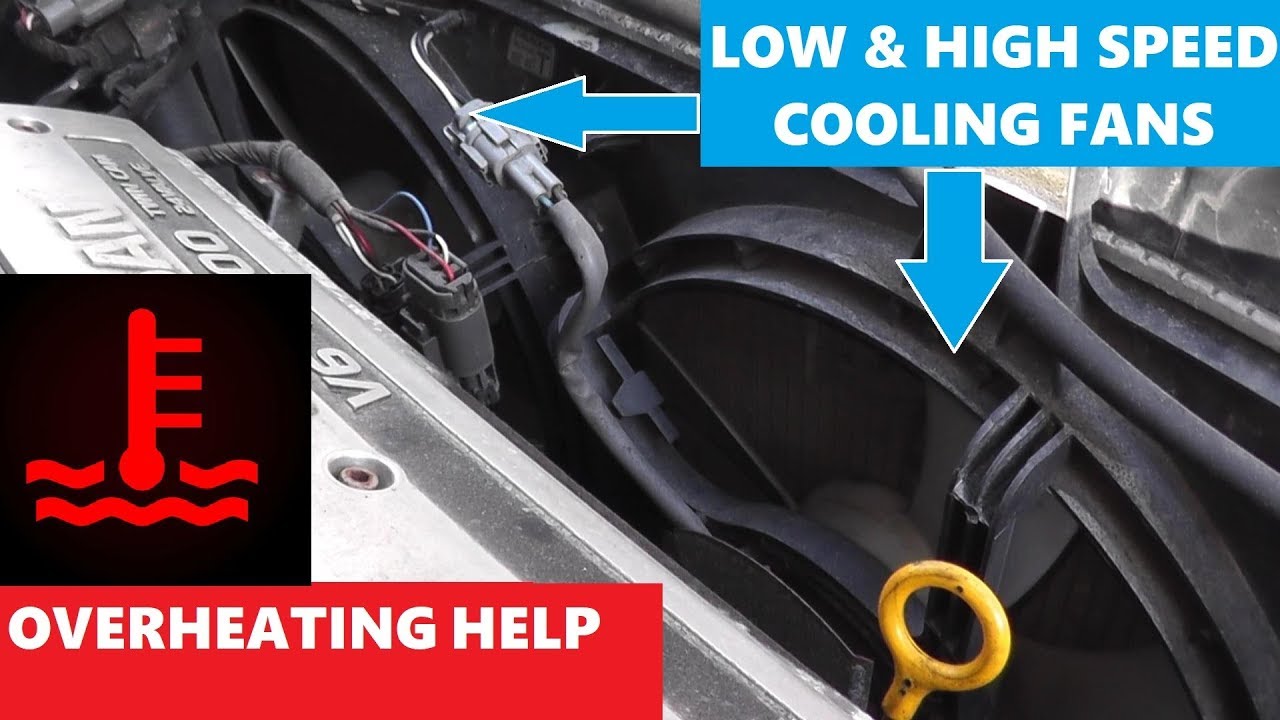

Overheating Help! | Testing Cooling Fans - Relays - Connections

What is a Motor Nameplate

Three phase motor forward and reverse circuit with Latch ON || Chain Hoist basic understanding

AHD CCTV camera installation step by step setup guide from beginning to end.

5 Formulas Electricians Should Have Memorized!

5.0 / 5 (0 votes)