Head loss due to friction in a pipe using Moody Diagram and the Darcy–Weisbach equation

Summary

TLDRThis video explains how to calculate the head loss due to friction in a 25-meter perspex pipe, using the Darcy-Weisbach equation and Moody diagram. The flow is analyzed at two different velocities, highlighting the transition from laminar to turbulent flow. The Reynolds number and friction factor are key to these calculations, which demonstrate how velocity and pipe roughness significantly affect energy loss. The results reveal that increasing velocity by a factor of 10 leads to a dramatic increase in head loss, and switching from a smooth pipe to a rough one doubles the loss, showcasing the importance of material and flow conditions in pipe design.

Takeaways

- 😀 The Darcy-Weisbach equation is used to calculate the total loss of head due to friction in a pipe.

- 😀 Reynolds number is a key factor in determining whether the flow is laminar or turbulent, influencing the friction factor.

- 😀 For laminar flow (Re < 2000), the friction factor is independent of the roughness of the pipe.

- 😀 For turbulent flow (Re > 4000), the friction factor is significantly influenced by the pipe's roughness and Reynolds number.

- 😀 The Moody diagram is essential for determining the friction factor based on Reynolds number and pipe roughness.

- 😀 The total head loss increases as the velocity of flow increases due to more friction in the pipe.

- 😀 The length of the pipe also contributes to the total loss of head, as a longer pipe results in more friction.

- 😀 The friction factor for a smooth perspex pipe was found to be 0.031, leading to a head loss of 0.089 meters at a velocity of 0.164 m/s.

- 😀 When the velocity increases to 1.64 m/s, the Reynolds number becomes turbulent (Re = 19680), leading to a significantly higher head loss of 7.85 meters.

- 😀 Changing the material of the pipe from a smooth perspex to a rough concrete pipe doubles the loss of head, highlighting the impact of pipe roughness on friction loss.

Q & A

What is the Darcy-Weisbach equation used for in this context?

-The Darcy-Weisbach equation is used to calculate the total loss of head due to friction in a pipe, considering the pipe's length, diameter, velocity, and the friction factor.

How does the velocity of the fluid affect the head loss due to friction?

-As the velocity of the fluid increases, the head loss due to friction also increases. This is because higher velocities generate more friction, which causes a higher energy loss in the system.

What is Reynolds number, and why is it important in this calculation?

-Reynolds number is a dimensionless number that helps determine whether the flow is laminar or turbulent. It is calculated using the formula: velocity * pipe diameter / kinematic viscosity. It is important because it influences the choice of friction factor based on the flow regime.

What does the Moody diagram represent, and how is it used in this example?

-The Moody diagram represents the relationship between Reynolds number, friction factor, and pipe roughness. It is used to determine the friction factor (f) for a given Reynolds number and pipe roughness by plotting the Reynolds number on the x-axis and finding the corresponding friction factor on the y-axis.

How is the friction factor (f) determined for laminar flow?

-For laminar flow, the friction factor is determined directly from the Moody diagram by finding the intersection of the Reynolds number line with the single black line corresponding to laminar flow.

What does it mean when the Reynolds number is above 4,000?

-When the Reynolds number is above 4,000, it indicates that the flow is turbulent, meaning that the fluid flow is chaotic and the friction factor can vary depending on the roughness of the pipe.

How does pipe roughness affect the friction factor in turbulent flow?

-In turbulent flow, pipe roughness increases the friction factor. The rougher the pipe surface, the higher the friction factor, which leads to greater head loss due to friction.

What is the significance of relative roughness in the Moody diagram?

-Relative roughness is the ratio of the pipe's roughness height to its diameter. It is significant because it determines which line in the Moody diagram corresponds to the pipe, influencing the calculation of the friction factor.

Why does the head loss increase by a factor of 88 when the velocity increases by a factor of 10?

-The increase in head loss by a factor of 88 occurs because head loss is proportional to the square of the velocity. A 10-fold increase in velocity results in a 100-fold increase in kinetic energy, but the friction factor and the specific characteristics of the flow cause this loss to be less than directly proportional.

How does the material of the pipe influence the total loss of head?

-The material of the pipe affects its roughness, which in turn affects the friction factor. A rougher pipe (e.g., concrete) increases the friction factor and, consequently, the total loss of head due to friction compared to a smooth pipe (e.g., perspex).

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

Perfiles de velocidad en tuberías circulares

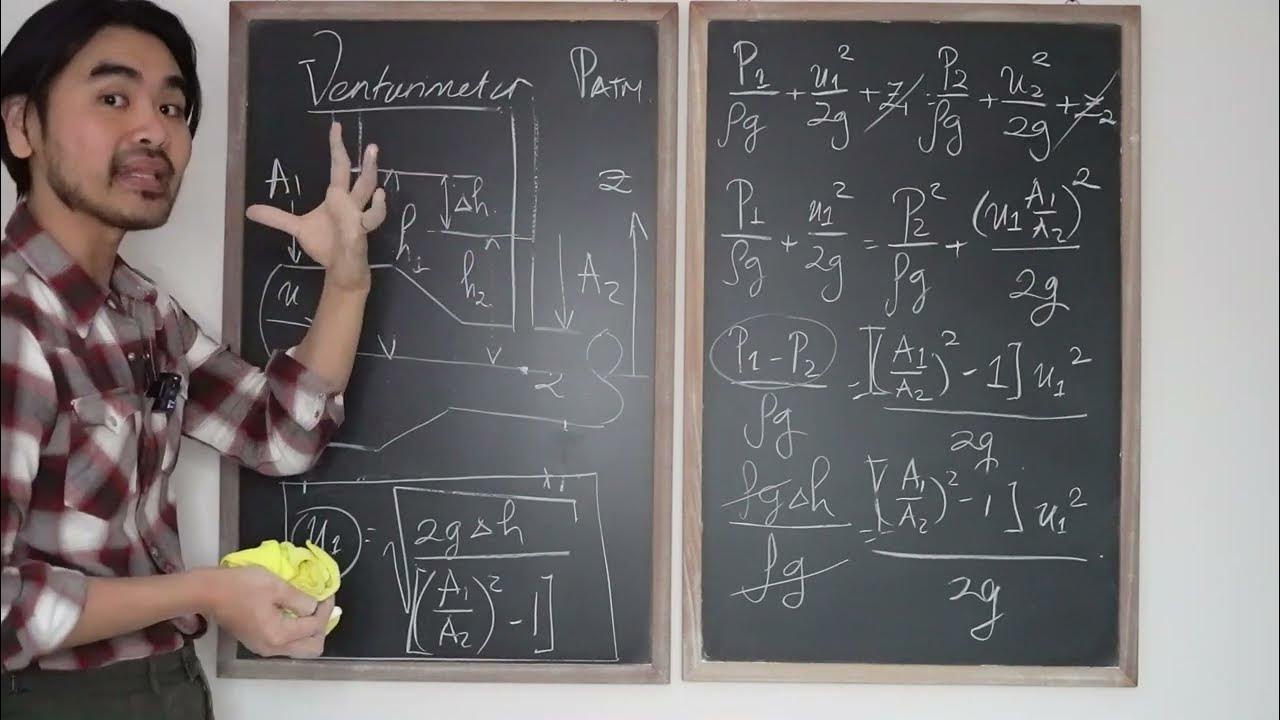

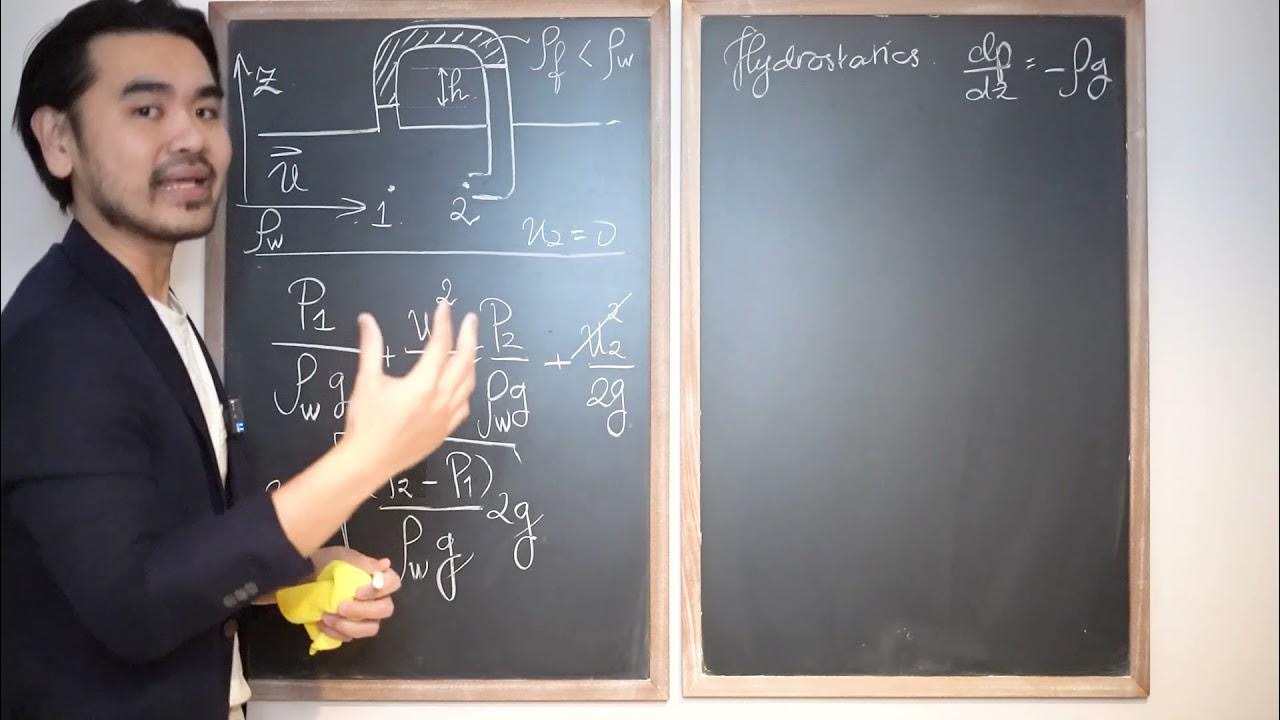

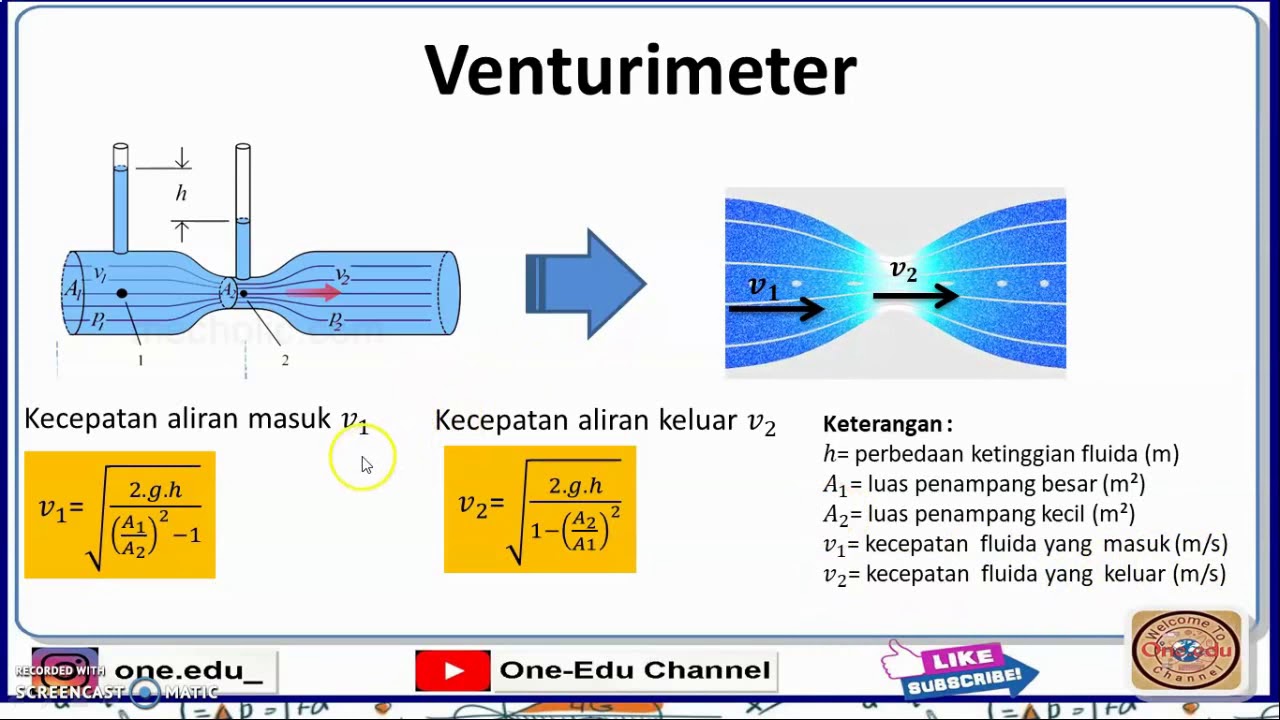

Mekanika Fluida FM01 (Lecture3: 6/8). Venturimeter - Aplikasi persamaan Bernoulli

Fluid Mechanics: Pipes in series (19 of 34)

Mekanika Fluida FM01 (Lecture3: 7/8). Static-Pitot Tube

Mekanika Fluida FM01 (Lecture3: 5/8). Kontinuitas (Continuity)

FISIKA KELAS XI: PENERAPAN HUKUM BERNOULLI PADA PIPA VENTURIMETER

5.0 / 5 (0 votes)