Ductile to Brittle Transition

Summary

TLDRThis video explains the ductile-to-brittle transition in materials, focusing on how temperature and material composition affect their behavior. It covers key concepts such as the stress-strain diagram for brittle and ductile materials, the Charpy Impact test for measuring fracture energy, and the influence of factors like carbon content, grain size, and strain rate on the transition temperature. The video also compares BCC and FCC materials, highlighting their different responses to temperature changes and their suitability for various engineering applications, especially in cryogenic environments.

Takeaways

- 😀 Brittle materials show little or no plastic deformation, and their failure occurs in the elastic regime.

- 😀 Ductile materials undergo significant plastic deformation before failure, absorbing more energy during fracture.

- 😀 The **Charpy Impact test** measures the energy absorbed during fracture and helps identify the ductile-to-brittle transition temperature (TDBT).

- 😀 Energy absorption during fracture is high for ductile materials and low for brittle materials.

- 😀 The **ductile-to-brittle transition** happens when a material changes from ductile behavior at higher temperatures to brittle behavior at lower temperatures.

- 😀 The **Charpy Impact test** involves a sample with a notch being struck by a pendulum, where the difference in potential energy before and after fracture determines the energy absorbed.

- 😀 In carbon steel, as carbon concentration increases, the ductile-to-brittle transition becomes more gradual, and the energy absorbed in the ductile regime decreases.

- 😀 **BCC materials** show a strong temperature dependence of yield stress, leading to a clear ductile-to-brittle transition, while **FCC materials** do not show this transition.

- 😀 Materials with fine grain size exhibit a lower ductile-to-brittle transition temperature, enhancing ductility.

- 😀 High strain rates and the presence of notches increase the brittleness of a material by raising the ductile-to-brittle transition temperature.

Q & A

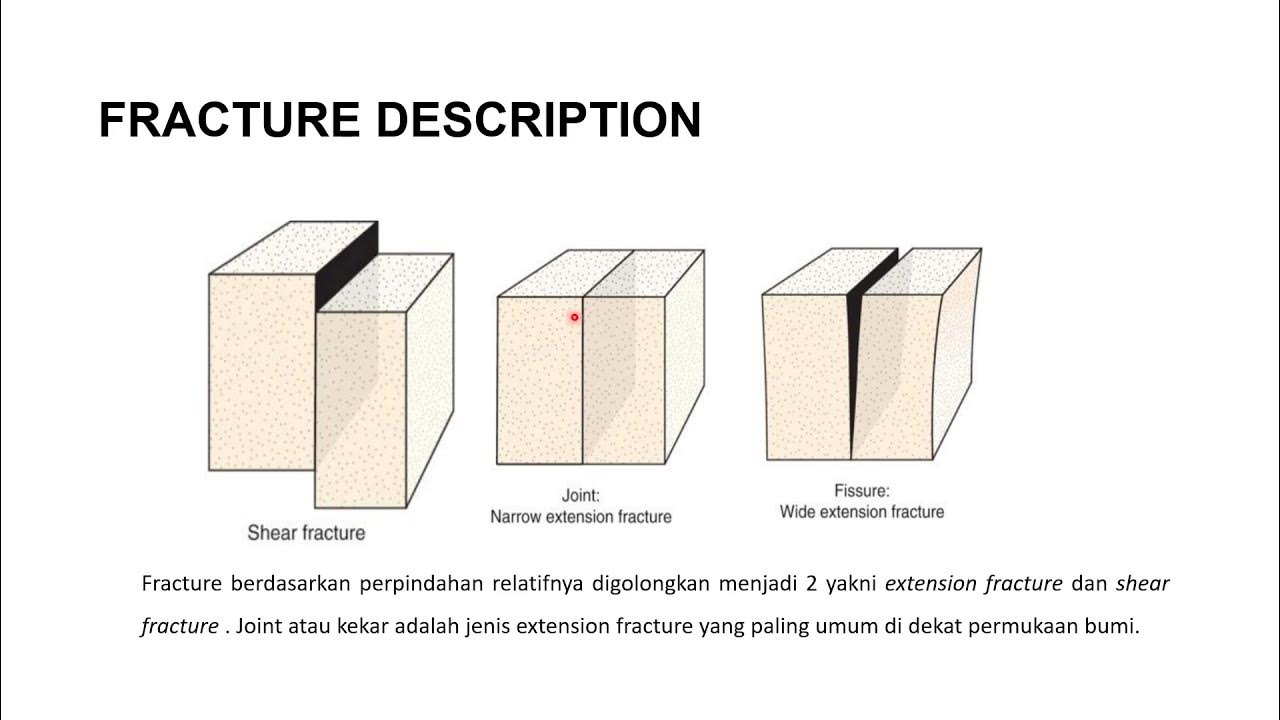

What is the key difference between ductile and brittle materials?

-Ductile materials undergo significant plastic deformation before fracture, while brittle materials fail with little or no plastic deformation, typically within the elastic regime.

How does the stress-strain diagram differ for ductile and brittle materials?

-For brittle materials, the stress-strain diagram is almost a straight line due to minimal plastic deformation. In contrast, ductile materials exhibit a larger curve due to significant plastic deformation before fracture.

How is energy absorbed during fracture represented in the stress-strain diagram?

-The energy absorbed during fracture is represented by the area under the stress-strain curve. This area is much larger for ductile materials than for brittle materials, indicating more energy absorption in ductile fractures.

What causes the ductile to brittle transition in materials?

-The ductile to brittle transition occurs when a material that is ductile at higher temperatures becomes brittle at lower temperatures, typically around room temperature.

What is the Charpy Impact Test and how does it measure the ductile to brittle transition?

-The Charpy Impact Test involves striking a notched specimen with a pendulum and measuring the energy absorbed during fracture. The absorbed energy, which is high in ductile fractures and low in brittle fractures, can be used to determine the ductile to brittle transition temperature.

How does carbon concentration affect the ductile to brittle transition?

-As the carbon concentration in steel increases, the material becomes more brittle, and the ductile to brittle transition temperature rises. This leads to a gradual transition in higher carbon steels.

What happens to the energy absorbed during fracture as carbon concentration increases in steel?

-As carbon concentration increases, the energy absorbed during the ductile fracture decreases, indicating increased brittleness of the material.

What role does grain size play in the ductile to brittle transition?

-A finer grain size lowers the ductile to brittle transition temperature, extending the ductile behavior range and enhancing material toughness.

How does strain rate affect the ductile to brittle transition?

-A higher strain rate increases the transition temperature, making the material more brittle, as it reduces the ability to undergo plastic deformation before fracture.

Why are FCC materials preferred for cryogenic applications?

-FCC materials do not exhibit a ductile to brittle transition, making them ideal for low-temperature (cryogenic) applications where ductility is required at very low temperatures.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade Now5.0 / 5 (0 votes)