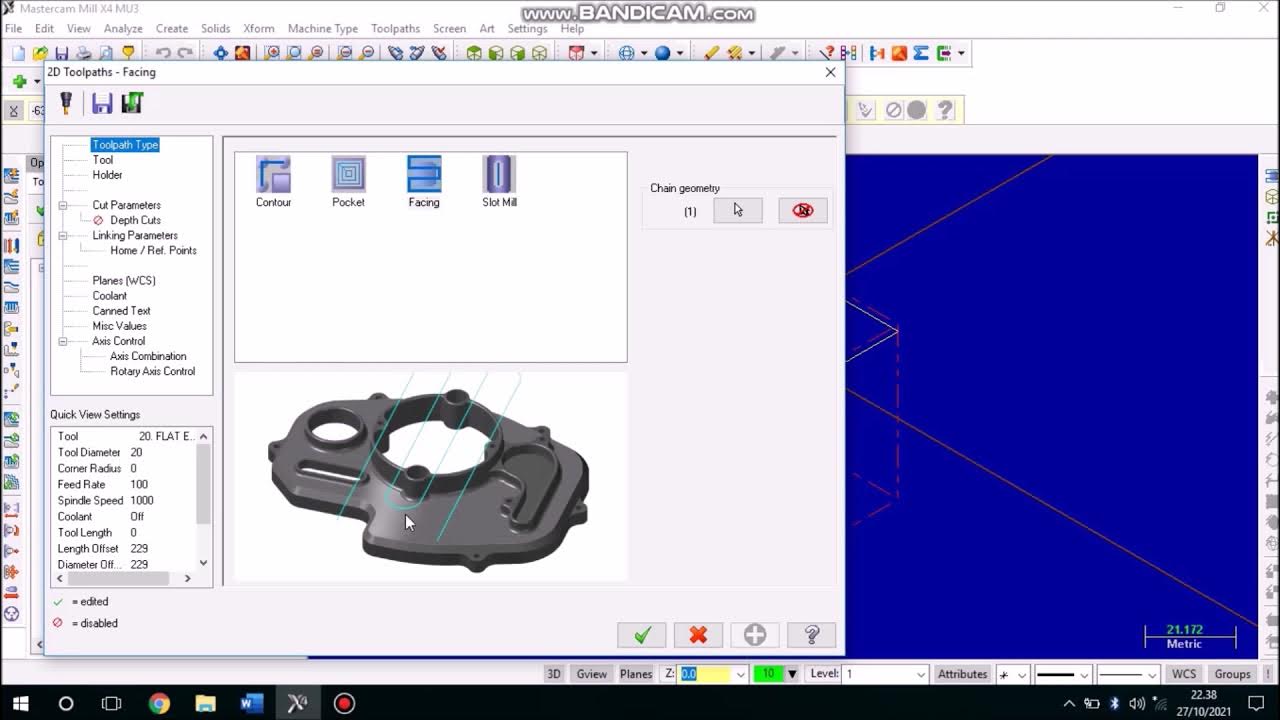

Peralatan Setting CNC Milling

Summary

TLDRThis video demonstrates the tools needed to set up a CNC machine, including the Centrofix or Adfender and the Zero Setter. The presenter explains how these tools work, with the Centrofix used for positioning and calibration, and the Zero Setter helping to ensure precise alignment by adjusting its needle to zero. The video guides viewers through the calibration process, including aligning moving and stationary parts, ensuring accuracy before proceeding with the CNC machine setup.

Takeaways

- 😀 The first tool needed for setting up a CNC machine is Centrofix or Adfender.

- 😀 These tools can be found on marketplaces, such as C marketplace, where they are sold.

- 😀 The Centrofix tool features a spring and a PR inside it, which is essential for machine setup.

- 😀 Another important tool is the Shertzer, which is used to manipulate or lift parts of the CNC machine.

- 😀 The Shertzer works by pressing a part of it to rotate the needle pedal, which plays a role in machine calibration.

- 😀 The Zero Setter tool is 50mm in height, from the bottom to the non-moving part of the device.

- 😀 It’s important to align the moving part of the Zero Setter with the non-moving part to achieve proper calibration.

- 😀 Calibration involves adjusting the Zero Setter so the needle aligns to the zero position.

- 😀 The adjustment is done by rotating the body or part of the tool until the needle reaches the zero position.

- 😀 A key part of the process is ensuring the needle accurately reaches the zero mark for correct calibration.

Q & A

What is the purpose of Centrofix or Adfender in CNC machine setup?

-Centrofix or Adfender is used for setting up the CNC machine. It helps in accurately positioning components during the calibration process.

Where can you find the Centrofix or Adfender tool?

-Centrofix or Adfender can be found on C marketplaces, where sellers list this tool for purchase.

What is the appearance of the Centrofix or Adfender tool?

-The Centrofix or Adfender tool looks like a cylindrical piece with a spring inside, along with a PR (likely referring to a specific component in the mechanism).

How does the Shertzer tool work in CNC machine setup?

-The Shertzer tool operates by pressing a part of the tool, which then makes the needle-like part rotate, aiding in the setup or calibration process.

What is a Zero Setter and what is its specific height?

-A Zero Setter is a device used for setting the height reference in CNC machining. Its height is 50 mm from the bottom to the stationary part of the tool.

How do you align the moving and stationary parts of the Zero Setter?

-To align the moving and stationary parts of the Zero Setter, they must be positioned at the same height, ensuring that they are aligned properly to achieve a 'zero' reference.

What should be the position of the needle on the Zero Setter after calibration?

-After calibrating, the needle should be at the zero position, indicating that the setup is correct and aligned properly.

How do you calibrate or reset the needle on the Zero Setter?

-To calibrate the needle, rotate the body or the leg of the Zero Setter until the needle shows the zero position, confirming that the calibration is successful.

What is the purpose of pressing the part on the Shertzer tool during calibration?

-Pressing the part on the Shertzer tool triggers the rotation of the needle, which helps in adjusting and setting the correct reference during the calibration process.

What is the significance of setting the machine to 'zero' during the CNC setup?

-Setting the machine to 'zero' during CNC setup is crucial as it defines the reference point for all subsequent operations, ensuring accurate machining and measurements.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade Now5.0 / 5 (0 votes)