Just in time or JIT | Advantages & Disadvantages of Just-in-time #justintime #jit

Summary

TLDRThis video explains the concept of Just in Time (JIT) inventory management, where goods are received from suppliers only as needed, helping reduce inventory costs and increase turnover. The process is outlined, from customer orders to product delivery. Benefits of JIT include reducing waste, lowering warehouse costs, giving manufacturers more control, enabling local sourcing, and requiring smaller investments. However, there are risks, such as running out of stock, lack of control over timeframes, and insufficient planning. Viewers are encouraged to share the video and subscribe for more educational content.

Takeaways

- 😀 Just In Time (JIT) is an inventory management strategy that focuses on receiving goods from suppliers only as needed.

- 😀 The main goal of JIT is to reduce inventory holding costs and increase inventory turnover.

- 😀 The JIT process begins when a customer places an order, triggering the manufacturer to order required materials from suppliers.

- 😀 The supplier delivers the materials to the manufacturer, who then converts them into the product ordered.

- 😀 JIT helps reduce inventory waste by eliminating overproduction and the accumulation of unsellable goods.

- 😀 By ordering only when needed, JIT minimizes warehouse costs, as inventory is not stored for long periods.

- 😀 Manufacturers have more control over production processes in JIT, responding quickly to demand for in-demand products and adjusting for slower-moving items.

- 😀 Local sourcing is encouraged in JIT to reduce transportation costs and ensure quicker delivery of materials.

- 😀 JIT requires smaller investments in stock, as only essential items are purchased, reducing working capital needs.

- 😀 One disadvantage of JIT is the risk of running out of stock if demand projections are inaccurate, leading to insufficient inventory.

- 😀 JIT depends on timely deliveries from suppliers, which can lead to delays if not properly managed, potentially harming customer satisfaction.

Q & A

What is Just In Time (JIT) inventory management?

-Just In Time (JIT) is an inventory management strategy where goods are received from suppliers only as they are needed in the production process. The goal is to minimize inventory holding costs and increase inventory turnover.

What is the main purpose of Just In Time inventory management?

-The main purpose of JIT is to reduce inventory holding costs and increase inventory turnover by ensuring that only the necessary materials are ordered and received when they are required.

What are the first steps in the Just In Time process?

-The process begins with a customer placing an order. The manufacturer then receives the order and orders the required materials from the supplier. The supplier delivers the materials to the manufacturer, who then processes the materials into the final product.

How does Just In Time reduce inventory waste?

-JIT reduces inventory waste by eliminating overproduction. It ensures that only the required quantity of materials is ordered, reducing the risk of excess inventory that cannot be sold.

What is the advantage of JIT in terms of warehouse costs?

-JIT minimizes warehouse holding costs because materials are only ordered when needed. This reduces the time items are stored, preventing unnecessary costs related to storing unsold goods.

How does Just In Time provide more control to manufacturers?

-JIT allows manufacturers to have more control over the production process by responding to customer demand. They can quickly increase production for in-demand products and reduce production for slow-moving items.

Why is local sourcing important in the Just In Time system?

-Local sourcing is crucial in JIT because it ensures that raw materials are delivered quickly and efficiently. It reduces transportation time and costs, making it easier to meet demand in a timely manner.

What is the impact of JIT on working capital?

-JIT reduces the need for large inventories, which leads to smaller investments in stocks. This results in a lower requirement for working capital, as only essential items are purchased.

What is the main risk of running a Just In Time system?

-The main risk is the possibility of running out of stock due to inaccurate demand projections. Since JIT relies on forecasts, any miscalculations can result in insufficient stock to meet customer demand.

What challenges does Just In Time face regarding supplier reliability?

-JIT is highly dependent on the punctuality of suppliers. Any delays in supplier deliveries can result in delayed production and missed customer delivery deadlines, which can damage customer satisfaction and harm business reputation.

Why is careful planning necessary in a Just In Time system?

-Careful planning is essential in JIT because businesses need to accurately predict sales trends and seasonal fluctuations. Without this understanding, companies may face issues with stock levels, especially during peak demand periods.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

O QUE É JUST IN TIME (Vantagens e Desvantagens)

[PRESENTASI] TEKNIK PERSEDIAAN METODE JIT (JUST IN TIME) DAN EOQ (ECONOMIC ORDER QUANTITY)

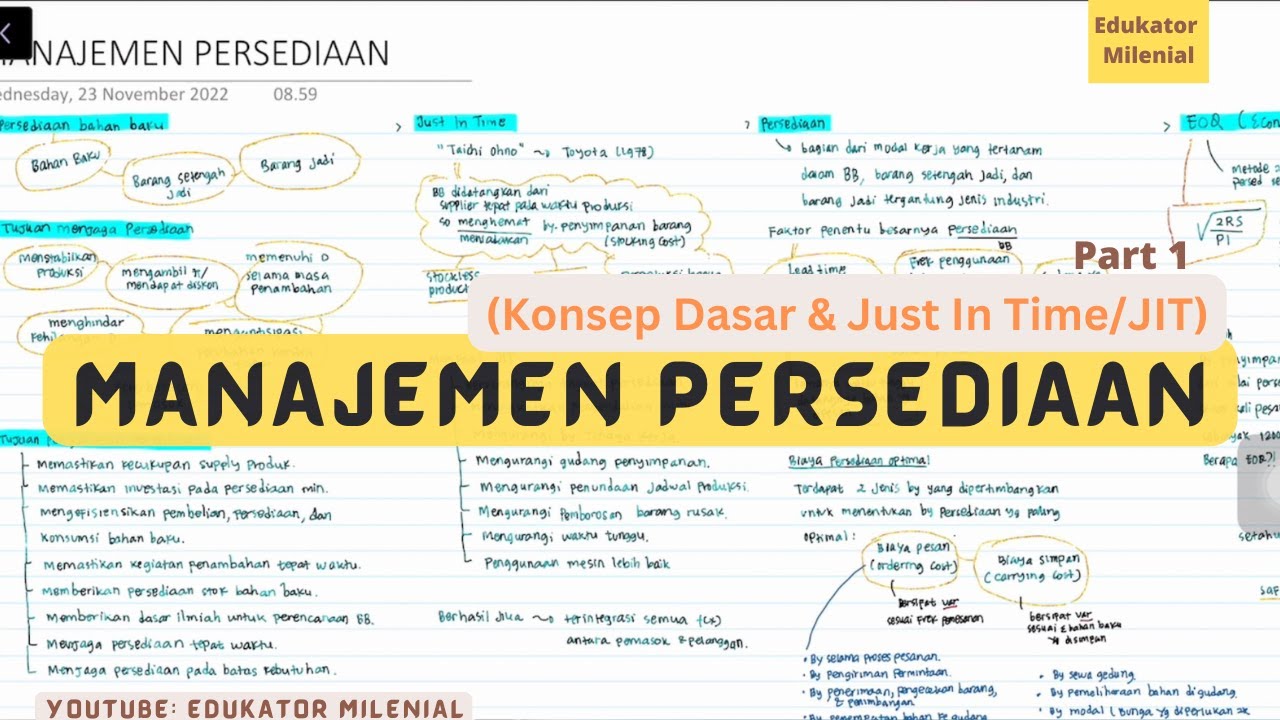

Manajemen Persediaan (Just In Time - JIT)

What is Inventory Control? Explained in 9 minutes

E learning : Manajemen Operasional - Sesi 8, Manajemen Persediaan | by Siti Mariam

Just In Time - How Toyota, McDonalds and Apple Use Just In Time - With Examples

5.0 / 5 (0 votes)