O QUE É JUST IN TIME (Vantagens e Desvantagens)

Summary

TLDRIn this video, the concept of Just in Time (JIT) is explained as a methodology that helps businesses minimize inventory and optimize costs by producing or purchasing goods only when needed. The video highlights the advantages of JIT, such as reduced waste, improved efficiency, and better communication, while also addressing its drawbacks like the reliance on demand predictability and supplier dependability. Seven practical tips are offered for implementing JIT effectively, including understanding its fit for your business, planning carefully, aligning with suppliers, and using tools like Kanban and supply chain management to streamline operations.

Takeaways

- 😀 Just in Time (JIT) is a production management strategy that focuses on producing and purchasing only the exact amount of materials or products needed, right when they are required.

- 😀 One of the main advantages of JIT is the reduction in inventory, which minimizes storage costs, space usage, and waste.

- 😀 JIT optimizes processes, requiring businesses to streamline operations and continuously improve efficiency.

- 😀 JIT requires precise planning throughout the entire production chain, ensuring every part of the business is aligned and organized.

- 😀 By producing only according to actual demand, JIT allows companies to enhance production efficiency and quality while eliminating excess.

- 😀 JIT relies heavily on suppliers being reliable and delivering materials on time, as any delays can disrupt the entire production process.

- 😀 A major disadvantage of JIT is its dependency on demand predictability; unexpected orders can lead to difficulties in fulfilling them.

- 😀 To apply JIT successfully, businesses must ensure a clear understanding of the demand forecast and plan processes accordingly.

- 😀 Successful JIT implementation requires well-trained teams that understand their roles and responsibilities in ensuring the process runs smoothly.

- 😀 Key tools for implementing JIT include supply chain management systems and Kanban, which help visualize workflows and ensure timely production.

- 😀 JIT is not suitable for all business models, so companies must analyze if it aligns with their needs and objectives before adopting it.

Q & A

What is the 'Just in Time' methodology?

-Just in Time (JIT) is a management strategy where a company purchases and produces only the exact amount of materials or products needed to meet customer demand at the right moment. It helps businesses optimize resources, reduce waste, and avoid excess inventory.

What are the main advantages of implementing Just in Time?

-The main advantages of JIT include reducing inventory and waste, optimizing production processes, ensuring better planning across the production chain, improving communication, and providing more control over manufacturing.

How does Just in Time help reduce waste?

-By minimizing excess inventory, JIT reduces the space, manpower, and costs associated with managing stock. It ensures that only the necessary materials and products are available when needed, resulting in less waste.

Why is demand predictability crucial for Just in Time?

-Predicting demand is essential for JIT because the methodology relies on having an accurate forecast to determine when and how much to produce. Without this, businesses may struggle to meet demand in a timely manner.

What are the risks associated with Just in Time?

-The main risks of JIT include difficulty handling unexpected orders, dependency on suppliers, and potential production interruptions if a supplier fails to deliver on time or provides incorrect materials.

What steps should a business take to implement Just in Time successfully?

-To implement JIT successfully, a business should first analyze if it fits their model, plan its goals and resources carefully, align with reliable suppliers, train the team, and track all processes consistently to ensure smooth operation.

What role do suppliers play in the Just in Time process?

-Suppliers are crucial in JIT because timely and accurate delivery of materials is essential for the system to function. Any delay or mistake from suppliers can cause significant disruptions in the production process.

Why is employee training important in a Just in Time system?

-Training is important because every employee needs to understand their role in the process and how it affects the overall production. This ensures efficiency and quality, helping the company meet its goals.

How can companies ensure quality control in Just in Time?

-Companies can ensure quality control in JIT by having standardized processes, carefully selecting suppliers, and continuously monitoring the production process to detect and address any issues that arise.

What are Kanban and Supply Chain, and how do they relate to Just in Time?

-Kanban is a visual system used to manage workflow and production. It helps to indicate and monitor the progress of production in real-time. The Supply Chain involves the entire process of producing and delivering products to customers. Both are integral to JIT as they ensure that production and supply are aligned with demand.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

[PRESENTASI] TEKNIK PERSEDIAAN METODE JIT (JUST IN TIME) DAN EOQ (ECONOMIC ORDER QUANTITY)

Just In Time JIT Definition Investopedia

Just In Time - How Toyota, McDonalds and Apple Use Just In Time - With Examples

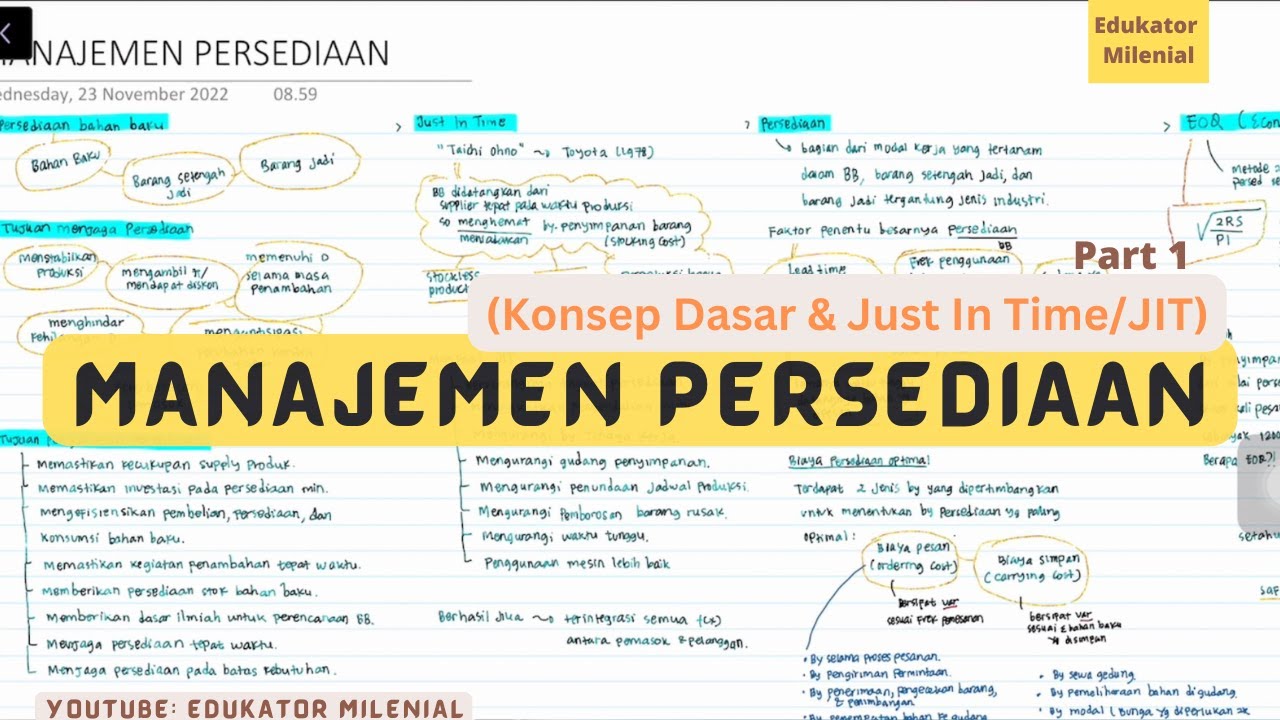

Manajemen Persediaan (Just In Time - JIT)

Just in time or JIT | Advantages & Disadvantages of Just-in-time #justintime #jit

Just in Time Production Explained | Toyota, Dell and Walmart Examples

5.0 / 5 (0 votes)