Elemen Mesin 1 pertemuan 7

Summary

TLDRThis lecture discusses V-belt transmission systems, which are used to transmit power and rotational motion. The instructor explains the basic principles of V-belt transmission, including how it increases torque or adjusts rotational speed. The advantages of V-belts include low maintenance, quiet operation, and flexibility, while also offering protection from motor damage through slippage. The session covers the different types and specifications of V-belts, as well as their applications in machinery. Additionally, the lecturer introduces methods for setting and measuring the tension of V-belts to ensure proper functioning, emphasizing the importance of correct tension for optimal performance and safety.

Takeaways

- 😀 Patience in following government protocols, like COVID-19 guidelines, is emphasized as a civic duty for all students and academics.

- 😀 The course material for today is based on Robert Mood's 'Machine Elements in Mechanical Design,' Mitsuboshi's 'V-Belt Design Manual,' and a YouTube video about setting V-belt tension.

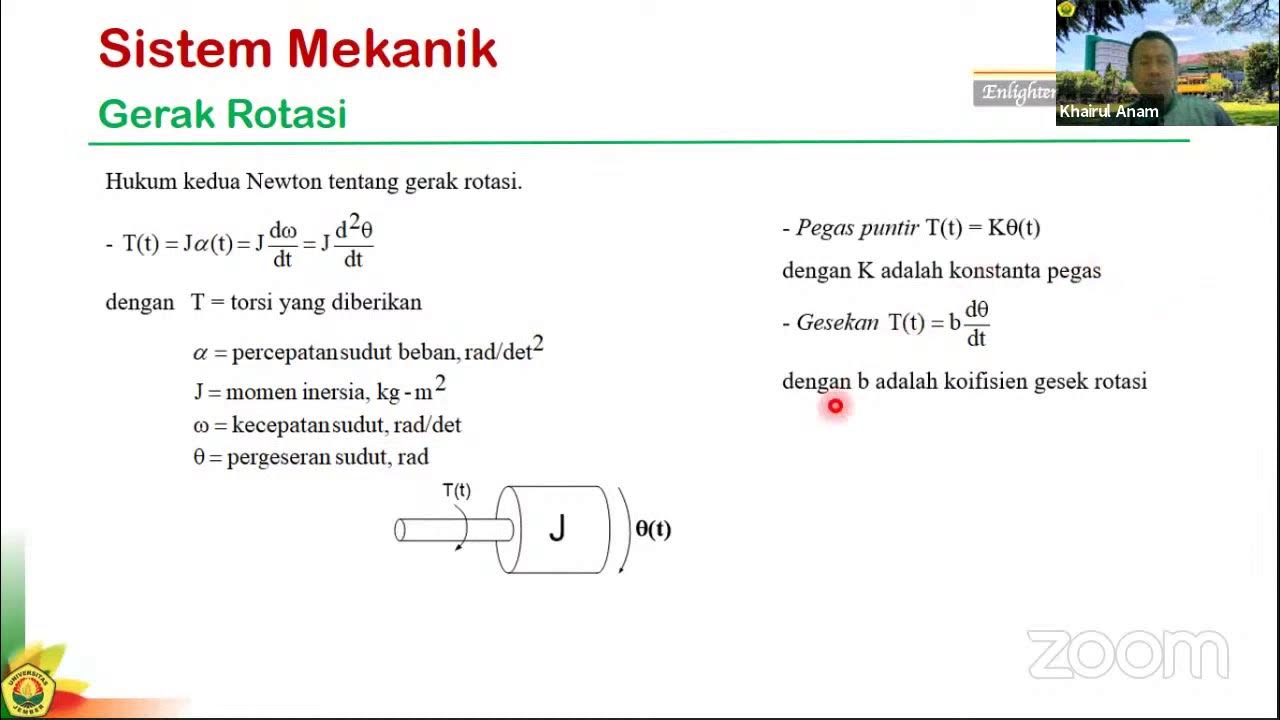

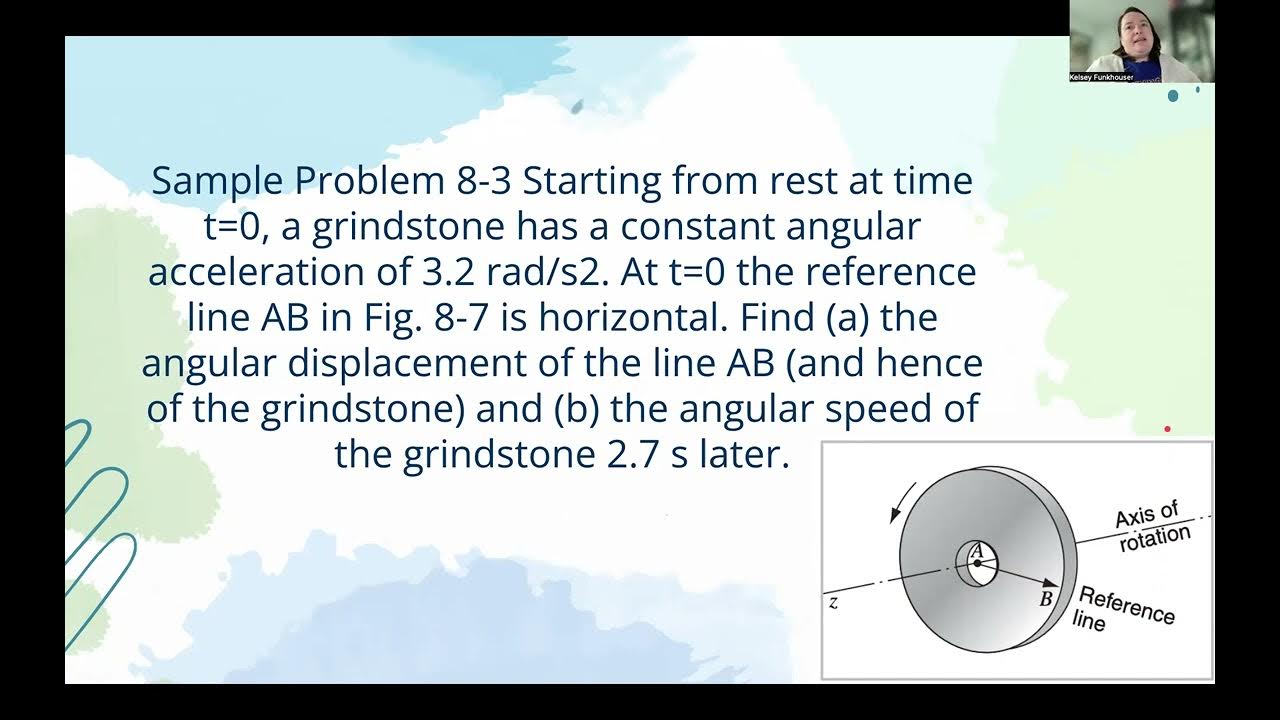

- 😀 Transmissions are devices used to transfer power and rotation, often used to increase torque by reducing speed or increase speed while decreasing torque, like in bicycles.

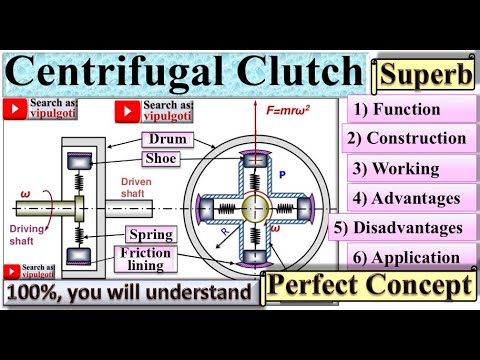

- 😀 V-belt transmissions are flexible due to their rubber composition, unlike rigid gear or chain transmissions.

- 😀 The key mechanism of V-belt transmission is friction between the belt and pulley, which transfers power and rotational motion without slippage.

- 😀 A worn-out V-belt, with a visible gap in the pulley groove, is an indicator for replacement to ensure proper functioning of the system.

- 😀 Advantages of V-belt transmissions include minimal noise, overload protection (slipping under excess load), and better shock absorption compared to chain systems.

- 😀 However, V-belt systems require dry conditions to function optimally, and their power efficiency is lower compared to chain systems due to slipping.

- 😀 V-belts are composed of multiple parts: the rubber body (for shock absorption), the reinforcing wire (for strength), and the fiber cover (for protection).

- 😀 Different types of V-belts are available, such as standard, narrow-section, and horsepower versions, each with specific applications and strength characteristics.

- 😀 Proper tension in a V-belt is crucial: too tight can damage bearings, and too loose can cause excessive vibration and power loss. Proper tension can be measured using a tension meter or ruler.

Q & A

What is the primary function of a V-belt transmission?

-A V-belt transmission primarily functions to transmit power and rotation between two pulleys, either increasing torque by reducing speed or increasing speed while reducing torque.

Why is a V-belt considered more flexible compared to gear transmissions?

-A V-belt is considered flexible because it is made of rubber, allowing it to bend and adapt to the pulleys, unlike rigid gear-based transmissions which cannot flex.

How does the V-belt transfer power and torque?

-The V-belt transfers power and torque through friction between its sides and the grooves of the pulleys. This friction ensures efficient transmission of rotational energy.

What are the main advantages of using a V-belt transmission?

-The main advantages of V-belt transmissions include quieter operation, ability to slip under overload conditions to prevent damage, shock absorption due to the rubber material, and low maintenance requirements.

What is a disadvantage of using V-belt transmissions in wet environments?

-V-belt transmissions are not ideal for wet environments because water can reduce the friction between the belt and pulleys, causing slip and decreased efficiency. Enclosures are typically used to protect V-belts in such conditions.

Why is the ability of a V-belt to slip under overload conditions considered an advantage?

-The ability to slip under overload conditions is advantageous because it prevents damage to the machinery. For example, it can protect electric motors from overheating or burning out by reducing the risk of jamming or excessive strain.

What materials are typically used to make the body of a V-belt?

-The body of a V-belt is typically made from a special rubber blend that provides good mechanical properties, including flexibility and shock absorption.

What role does the reinforcement material play in a V-belt?

-The reinforcement material, usually steel wire mesh, increases the tensile strength of the V-belt, helping it resist stretching and breaking under tension, ensuring it can handle higher loads without damage.

What are the key differences between standard V-belts and narrow V-belts?

-Standard V-belts are used for heavier loads and have a broader cross-section, while narrow V-belts are designed for lighter loads and have a smaller cross-section, allowing them to fit in tighter spaces.

How is V-belt tension typically measured and adjusted?

-V-belt tension is measured by applying pressure to the belt and checking the deflection. A specific tension level, such as 5.5 pounds of force, is required for optimal performance. If the tension is too high or low, it can be adjusted using tensioning tools or by repositioning the pulleys.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

5.0 / 5 (0 votes)