Steel Plate Girder (Eurocode 3)-Summary By Dr.Ina

Summary

TLDRThis lecture introduces the fundamentals of steel plate girder design, highlighting key concepts such as the differences between universal beams and fabricated plate girders, as well as the failure modes including web buckling, flange buckling, and lateral torsional buckling. The importance of stiffeners, including load-carrying, load-bearing, and intermediate types, is emphasized to prevent these failures. The design process involves calculating web thickness, checking bending resistance, dimensioning the web, and designing stiffeners. Students will learn how to analyze and design plate girders for various loads and conditions, ensuring structural integrity in applications like bridges and industrial structures.

Takeaways

- 😀 Plate girders are structural members primarily used to resist loads in bending and shear, often in bridge construction and industrial structures.

- 😀 Plate girders are made up of flange plates and a web plate, which can be of different steel grades and sizes chosen by the designer.

- 😀 The key difference between a beam and a girder is the size of the component, with plate girders typically being larger and having higher moment, shear, and deflection capacity.

- 😀 Plate girders are commonly used for spans up to 15 meters and are designed to carry heavy loads with a deeper section for higher stiffness.

- 😀 The web of a plate girder is prone to buckling due to its thin structure, which is why stiffeners are used to prevent this failure mode.

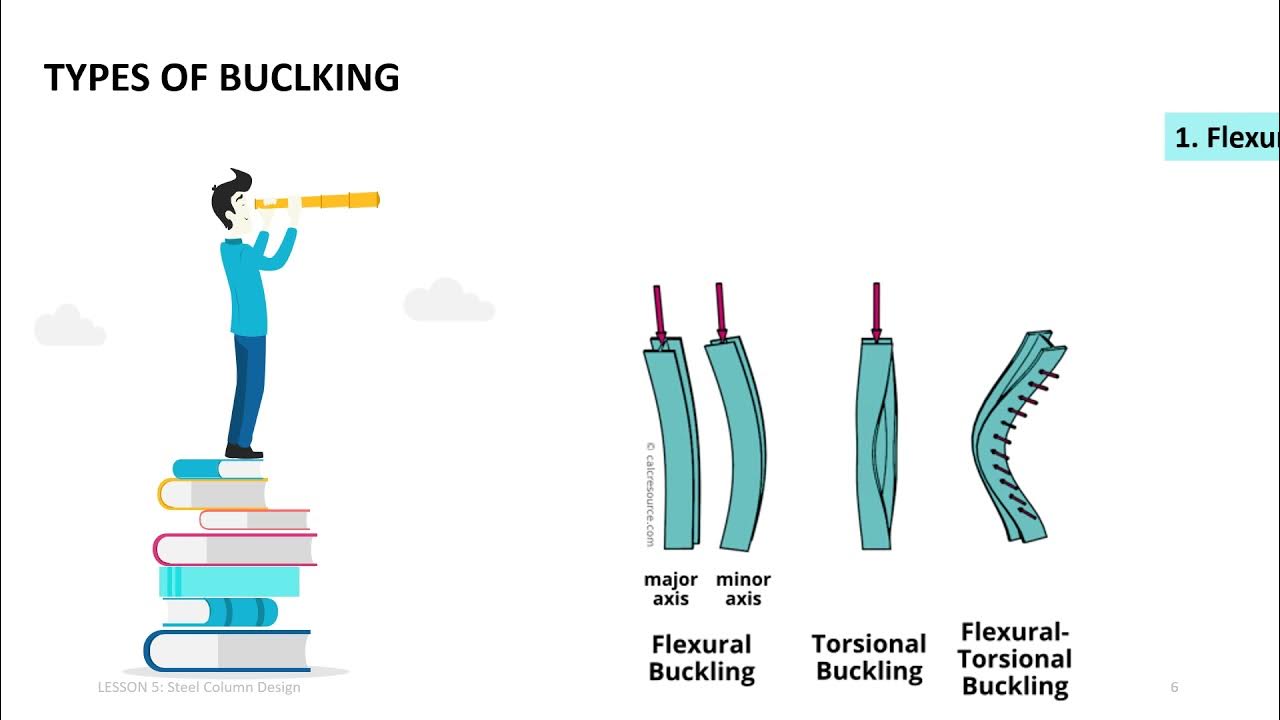

- 😀 Plate girders can fail due to web buckling, flange buckling, lateral torsional buckling, or vertical flange buckling, among other possible failure modes.

- 😀 To prevent lateral torsional buckling, adequate lateral restraints like composite slabs can be used.

- 😀 Transverse stiffeners are used to combat web buckling and provide support to concentrated loads or reactions in plate girders.

- 😀 There are three types of transverse stiffeners: load-carrying stiffeners, load-bearing stiffeners, and intermediate stiffeners, each serving a specific function in preventing failure modes.

- 😀 Tension field action can significantly enhance the shear capacity of plate girders after the onset of web buckling, improving the girder's overall strength.

- 😀 The design process for a plate girder involves calculating minimum web thickness, analyzing bending resistance, and designing stiffeners to ensure the girder can safely withstand applied loads.

Q & A

What is the primary function of a steel plate girder?

-A steel plate girder primarily resists bending and shear, and is used to carry heavy loads over long spans, typically in bridge construction, industrial structures, and building floor systems.

What is the key difference between a universal beam and a fabricated plate girder?

-The key difference is that plate girders are larger and built-up structural members consisting of flange and web plates, designed for heavier loads and longer spans. Universal beams are solid beams, typically used for shorter spans and lighter loads.

Why are stiffeners necessary in plate girder design?

-Stiffeners are necessary to prevent web buckling, which can occur due to the high shear forces in the thin web. They also support concentrated loads or reactions and help control lateral torsional buckling.

What are the main failure modes in a plate girder?

-The main failure modes include web buckling due to shear or bending, flange local buckling, lateral torsional buckling, and vertical flange buckling, which may occur separately or in combination.

What is tension field action in plate girders?

-Tension field action refers to the phenomenon where the shear capacity of a plate girder is significantly enhanced after the onset of local shear buckling, improving the girder's overall shear resistance.

What are the different types of stiffeners used in plate girders?

-The three types of stiffeners are load-carrying stiffeners, load-bearing stiffeners, and intermediate stiffeners. Load-carrying and load-bearing stiffeners are designed to address web buckling and web bearing issues, while intermediate stiffeners are used to maintain web stability.

How are plate girders typically fabricated?

-Plate girders are fabricated by welding flange plates and a web plate together using automatic electric arc welding or submerged gas welding. This is typically done in a double pass—one on either side of the girder.

What is the common span range for plate girders?

-Plate girders are commonly used for spans up to 15 meters, but they can be designed for longer spans depending on the required load capacity and structural design.

What is the role of transverse stiffeners in plate girders?

-Transverse stiffeners help combat the effects of web buckling and provide support to any concentrated load or reaction along the length of the girder, improving its load-carrying capacity.

What are the five basic steps in the design procedure for a steel plate girder?

-The five basic steps include: 1) calculating the minimum web thickness, 2) evaluating bending resistance, 3) dimensioning the girder, 4) designing the web, and 5) designing the stiffeners.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

Steel Column Design (EC3) Summary by dRBI

Pola Kegagalan Balok Lentur: Lateral Torsional Buckling, Tekuk Lokal, Plastik Sempurna Struktur Baja

Lateral Torsional Buckling Introduction

Balok Lentur dengan Tekuk Lokal Menurut SNI 1729-2015 | Struktur Baja | Lightboard

Batang Lentur 1 Compact Section

Plastik Sempurna pada Balok | Cara Menghitung Plastic Section Modulus | Struktur Baja | Lightboard

5.0 / 5 (0 votes)