Pola Kegagalan Balok Lentur: Lateral Torsional Buckling, Tekuk Lokal, Plastik Sempurna Struktur Baja

Summary

TLDRThis video provides an in-depth analysis of three potential failure modes in flexural beams, specifically focusing on lateral torsional buckling, local buckling of flanges and webs, and the occurrence of perfect plasticity or general yielding. The video highlights how these phenomena occur and offers solutions to prevent them, such as providing lateral support and ensuring correct flange-to-thickness ratios. By avoiding these failure modes, a beam can achieve perfect plasticity, where the entire cross-section undergoes yielding. The video also outlines methods for calculating the beam's nominal strength in each failure scenario, aimed at enhancing structural integrity and design.

Takeaways

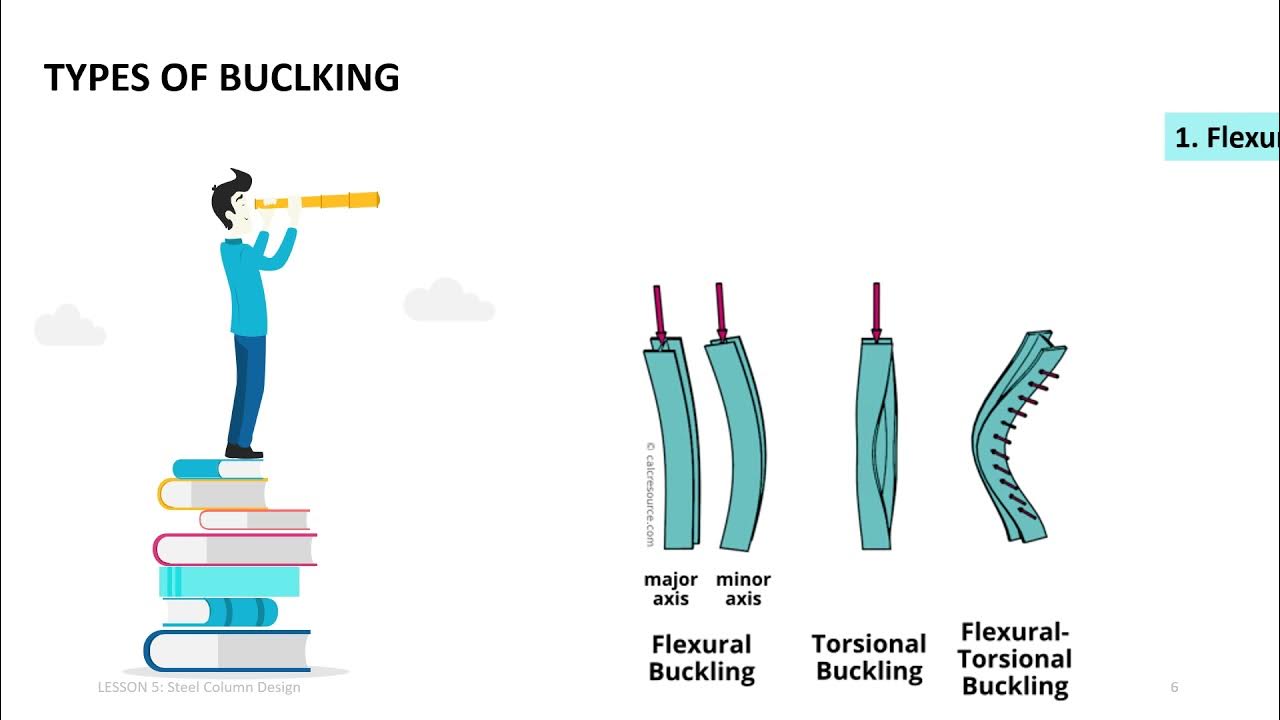

- 😀 Lateral Torsional Buckling (LTB) occurs when the beam bends laterally, causing the top to experience compression and the bottom tension, leading to the beam 'tipping over'.

- 😀 To prevent Lateral Torsional Buckling, lateral support can be provided, such as using zircon connectors to attach the beam to concrete plates.

- 😀 An alternative method to prevent LTB is using a child beam that provides lateral support to the parent beam.

- 😀 In bridges, lateral support between beams is often provided by diaphragms, which prevent the beams from tipping by binding them together at the top.

- 😀 Local Buckling occurs when part of the beam, such as the flange or web, buckles due to an unfavorable width-to-thickness ratio.

- 😀 To prevent Local Buckling, maintain proper width-to-thickness ratios for both the flange and web of the beam, ensuring they do not exceed specific limits.

- 😀 The flange of the beam is particularly prone to local buckling when its width-to-thickness ratio is too large.

- 😀 The web of the beam can experience local buckling under shear forces, causing it to ripple and form wave-like patterns.

- 😀 Perfect Plasticity (Plastic Collapse) happens when the beam reaches its maximum strength and the entire section, from top to bottom, undergoes yielding.

- 😀 Perfect Plasticity only occurs if both LTB and Local Buckling are prevented. The beam will fail in perfect plasticity when all fibers reach yield stress, indicating maximum load capacity.

Q & A

What are the three failure modes discussed in the video?

-The three failure modes discussed in the video are lateral torsional buckling (LTB), local buckling in the wings or body of the beam (web), and plastic failure (general yielding).

What causes lateral torsional buckling (LTB) in bending beams?

-Lateral torsional buckling occurs when a beam, subjected to transverse loading, experiences twisting or buckling in the direction of its weaker axis. This causes the beam to rotate or 'tilt' out of place.

How can lateral torsional buckling (LTB) be prevented in a beam?

-Lateral torsional buckling can be prevented by providing lateral support, such as using a connector or anchoring the beam to a concrete slab to prevent the beam from tipping over.

What is the role of lateral support in preventing LTB?

-Lateral support helps stabilize the beam and prevents it from twisting or rotating. The support ensures that the beam remains straight under loading, thus avoiding lateral torsional buckling.

What is local buckling and how does it affect bending beams?

-Local buckling occurs when specific areas of a beam, such as the wings (flanges) or the web (body), buckle under stress, causing failure at localized points rather than along the entire beam.

What are the key factors to prevent local buckling in bending beams?

-To prevent local buckling, it is important to maintain the correct ratio of the beam's width to its thickness, ensuring that the dimensions are not too thin or weak to withstand stress.

What happens during plastic failure (general yielding) in a bending beam?

-Plastic failure occurs when the beam's material begins to yield uniformly across its section. This results in the entire beam reaching its maximum capacity and undergoing permanent deformation, typically at the point where the material experiences the highest stress.

How does avoiding lateral torsional buckling and local buckling lead to plastic failure?

-By preventing lateral torsional buckling and local buckling, the beam can reach its maximum strength without premature failure. This allows the beam to undergo general yielding, where the material deforms uniformly, reaching a condition known as plastic failure or 'perfect yielding.'

What is the significance of the width-to-thickness ratio in preventing failure modes?

-The width-to-thickness ratio of the beam's components, such as the flange and web, must be kept within certain limits to prevent local buckling. If the ratio is too large, it can lead to localized buckling, whereas if it's properly maintained, the beam can resist failure.

What will be covered in the upcoming videos related to beam failure analysis?

-The upcoming videos will focus on how to calculate the nominal strength of beams, considering the different failure modes. Specifically, they will teach how to determine the strength of a beam when it undergoes plastic failure, local buckling, or lateral torsional buckling.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

Steel Column Design (EC3) Summary by dRBI

Plastik Sempurna pada Balok | Cara Menghitung Plastic Section Modulus | Struktur Baja | Lightboard

Lateral Torsional Buckling Introduction

Steel Plate Girder (Eurocode 3)-Summary By Dr.Ina

Batang Lentur 1 Compact Section

Contoh Perhitungan Analisa Balok Lentur dengan Tekuk Lokal | SNI 1729-2015 Struktur Baja Lightboard

5.0 / 5 (0 votes)