4 point starter | 4 point starter dc motor | four point starter | four point starter of dc motor

Summary

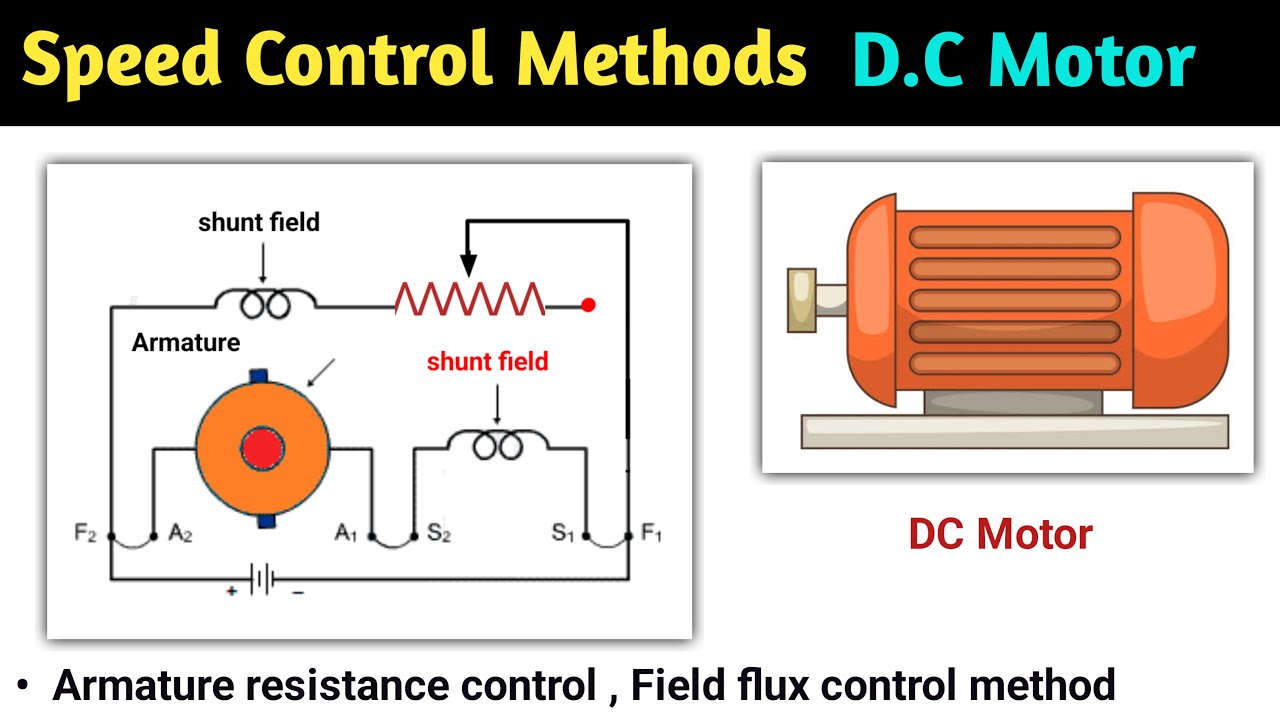

TLDRThe lecture delves into the workings and construction of four-point starters, a device used to protect DC motors from high starting current. It explains the similarities with three-point starters and the modifications made in four-point starters, such as removing the holding coil from the field circuit. The video also covers the step-by-step operation of starters, the role of electromagnetic products in holding and overload conditions, and the principles behind DC motor speed control. It concludes with applications of DC series and shunt motors in various systems and the advantages and disadvantages of using DC motors.

Takeaways

- 😀 A four-point starter is a device used to protect DC motors from high starting current.

- 🔧 The functional characteristics of a four-point starter are almost similar to a three-point starter, but it also provides protection.

- 🛠 In a four-point starter, modifications are made such as removing the holding coil from the field circuit, leaving a total of four terminals.

- 🔌 The construction and working principle of a four-point starter are almost like a three-point starter, with a four graded resistance connected in series.

- 🔄 When the handle is moved to the start position, the current flows through the armature windings due to the starting current after crossing the resistance.

- 🔋 After starting, the handle is moved to the run position, where the current does not drop across any resistance, allowing the motor to operate at full rated current.

- 🧲 An electromagnetic hold is used in the run position to keep the handle in place, and an overload coil is used as a protective device.

- ⚙️ In overload conditions, when the current exceeds a certain value, the overload coil attracts a strip 'P', causing the NBC coil to short-circuit, reducing the voltage and de-magnetizing the electromagnetic hold, thus returning the handle to the off position.

- 🔌 The main drawback of a three-point starter is that the field winding is connected in series with the NBC, which affects the magnetizing property and can cause the handle to move to the off position.

- 🔄 To overcome this drawback, a three-parallel circuit arrangement is made in the four-point starter, ensuring that any variation in current value does not affect the NBC.

- 🛠️ Comparing four-point and three-point starters, the four-point starter consists of four terminals and is a type of DC motor starter that connects through four terminals, unlike the three-point starter which connects through three terminals.

Q & A

What is a Four-Point Starter and why is it used?

-A Four-Point Starter is a type of device used to protect DC motors from high starting current. It functions similarly to a three-point starter but includes modifications to enhance protection.

How is the functionality of a Four-Point Starter similar to a Three-Point Starter?

-The functionality of a Four-Point Starter is almost similar to a Three-Point Starter as both provide protection to the DC motor. However, the Four-Point Starter includes additional modifications for better protection.

What is the main difference between a Four-Point Starter and a Three-Point Starter in terms of construction?

-In a Four-Point Starter, the holding coil is removed from the series field circuit, and there is a total of four terminals, unlike the Three-Point Starter which has three terminals.

What are the components of a Four-Point Starter's construction?

-A Four-Point Starter consists of a starter for the terminal, a non-adjacent four-point starter, a date line terminal, a field coil terminal, and a major terminal.

How does the operation of a Four-Point Starter protect the DC motor during starting?

-During starting, the handle of the Four-Point Starter is moved to the starting position, allowing the current to flow through the armature windings due to the current in the series resistance, which drops after crossing the resistance. This limits the current and protects the motor.

What is the role of the electromagnetic hold in a Four-Point Starter?

-The electromagnetic hold in a Four-Point Starter maintains the handle in the run position, ensuring that the motor operates at full rated current without any drop in the resistance cross.

How does the overload coil function in a Four-Point Starter?

-The overload coil in a Four-Point Starter is a protective device that, when the current value exceeds a certain level, attracts the strip 'P' with the help of the electromagnet, causing the NBC coil to short-circuit and reducing the voltage in the NBC coil to zero, which in turn demagnetizes the electromagnet and allows the handle to return to the off position.

What is the main drawback of using a Three-Point Starter compared to a Four-Point Starter?

-The main drawback of a Three-Point Starter is that the magnetic properties of the NBC coil, which is connected in series with the DC motor's field winding, decrease as the field fluxes are reduced, causing the handle to move to the off position, which is not an issue in a Four-Point Starter due to its three parallel circuit arrangement.

How do the terminals of a Four-Point Starter compare to those of a Three-Point Starter?

-In a Three-Point Starter, there are line terminal, armature terminal, and field terminal. In contrast, a Four-Point Starter has four terminals including an additional terminal for the NBC coil connection between the armature and field.

What is the significance of the equation 'Ae = V * (1 - (Ra/Rf))' in the context of a DC shunt motor?

-The equation represents the relationship between the armature current (Ia) and the field current (If) in a DC shunt motor. It shows that the armature current is inversely proportional to the field resistance (Rf), meaning that increasing the field resistance decreases the armature current, which in turn increases the motor speed.

What are some applications of DC series motors mentioned in the script?

-DC series motors are used in applications such as air compressors, lifts, elevators, winches, electric traction, vacuum cleaners, and speed regulation applications.

What are the advantages of using a DC shunt motor in various applications?

-DC shunt motors are advantageous due to their quick starting, stopping, reversing, and fast acceleration capabilities. They are also suitable for applications requiring a wide range of speed control and can handle heavy loads.

What are the disadvantages associated with using DC motors?

-The disadvantages of DC motors include a higher initial cost, high maintenance cost due to the presence of commutators and brushes, and火花 generation near the brushes, making them unsuitable for explosive environments.

Outlines

Этот раздел доступен только подписчикам платных тарифов. Пожалуйста, перейдите на платный тариф для доступа.

Перейти на платный тарифMindmap

Этот раздел доступен только подписчикам платных тарифов. Пожалуйста, перейдите на платный тариф для доступа.

Перейти на платный тарифKeywords

Этот раздел доступен только подписчикам платных тарифов. Пожалуйста, перейдите на платный тариф для доступа.

Перейти на платный тарифHighlights

Этот раздел доступен только подписчикам платных тарифов. Пожалуйста, перейдите на платный тариф для доступа.

Перейти на платный тарифTranscripts

Этот раздел доступен только подписчикам платных тарифов. Пожалуйста, перейдите на платный тариф для доступа.

Перейти на платный тарифПосмотреть больше похожих видео

3 point starter | 3 point starter dc motor | three point starter of dc motor | three point starter

speed control of dc motor | speed control of dc shunt motor | dc motor speed control | series motor

Como Funciona un Motor Eléctrico de Corriente Continua ( DC ) ⚡ | Animación 3D

Motor de corriente CONTINUA y ALTERNA► [DIFERENCIAS] ✅

Slip ring Induction Motor, How it works?

DC Motor, How it works?

5.0 / 5 (0 votes)