Motor de corriente CONTINUA y ALTERNA► [DIFERENCIAS] ✅

Summary

TLDRThis video explores the differences between DC (Direct Current) and AC (Alternating Current) motors, commonly known as CEE and ACE motors in Spanish. DC motors are powered by a constant flow of electricity, often from batteries or DC power supplies, while AC motors operate on varying currents. The construction of DC motors includes brushes and a commutator, which can increase maintenance needs and limit speed and lifespan. Conversely, AC motors are brushless, offering robustness and longevity. Speed control in DC motors is achieved by varying the current in the rotor's winding, whereas AC motors' speed is adjusted by changing the frequency, typically with a frequency converter. The video invites viewers to like, comment, and subscribe for more informative content.

Takeaways

- 🔋 DC Motors are powered by direct current, such as from batteries or DC power supplies.

- 🌀 AC Motors are powered by alternating current, which is commonly supplied by the power grid.

- 🛠️ DC motors are constructed with brushes and a commutator, which can increase maintenance needs and limit speed and lifespan.

- 💪 AC motors do not use brushes, making them more robust with a longer lifespan.

- 🔄 The main difference between DC and AC motors lies in their power source, with DC motors using direct current and AC motors using alternating current.

- 🔧 DC motor speed is controlled by varying the current in the armature winding, specifically the rotor.

- ⚙️ AC motor speed is controlled by varying the frequency, often done with a frequency converter.

- 🛑 Brushes in DC motors can lead to increased wear and maintenance, affecting the motor's performance and lifespan.

- 🔧 The construction of AC motors without brushes contributes to their reliability and efficiency.

- 📈 Speed control in DC motors involves adjusting the current in the rotor, while in AC motors, it involves adjusting the frequency of the supplied current.

- 📚 Understanding the differences between DC and AC motors is crucial for selecting the right motor for various applications.

Q & A

What is the main topic of the video?

-The main topic of the video is the differences between DC (Direct Current) and AC (Alternating Current) motors.

What does 'DC' stand for in the context of the video?

-'DC' stands for Direct Current, which is the type of electrical current used to power DC motors.

What does 'AC' stand for and what is its significance in motor operation?

-'AC' stands for Alternating Current, which is the type of electrical current that powers AC motors.

How do DC and AC motors convert electrical energy?

-Both DC and AC motors convert electrical energy into mechanical energy.

What is the primary difference between DC and AC motors in terms of power source?

-The primary difference is that DC motors are powered by direct current, such as from batteries or DC power supplies, while AC motors are powered by alternating current.

What are the components that DC motors are typically built with?

-DC motors are typically built with commutators and brushes, which increase maintenance and affect speed and lifespan.

How do the construction differences between DC and AC motors affect their robustness and lifespan?

-AC motors do not use commutators and brushes, making them more robust with a longer lifespan compared to DC motors with commutators.

How is the speed of a DC motor controlled?

-The speed of a DC motor is controlled by varying the current in the rotor's winding.

What is used to control the speed of an AC motor?

-The speed of an AC motor is controlled by varying the frequency, commonly done with a frequency converter.

What is a common device used to convert AC current to DC current?

-A common device used to convert AC current to DC current is a converter or an AC/DC converter.

What are some of the implications of using a motor with brushes and commutators?

-Using a motor with brushes and commutators can increase maintenance requirements, limit speed, and reduce the lifespan of the motor.

What does the acronym 'CC' stand for in the context of the video?

-In the context of the video, 'CC' stands for Continuous Current, which is another term for Direct Current (DC).

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

PERBEDAAN ARUS AC DAN ARUS DC | KELEBIHAN DAN KEKURANGAN

AC vs. DC

Electrical Engineering: Basic Concepts (4 of 7) Electric Current: DC vs AC

Introduction to AC Circuits - AC Circuits - Basic Electrical Engineering

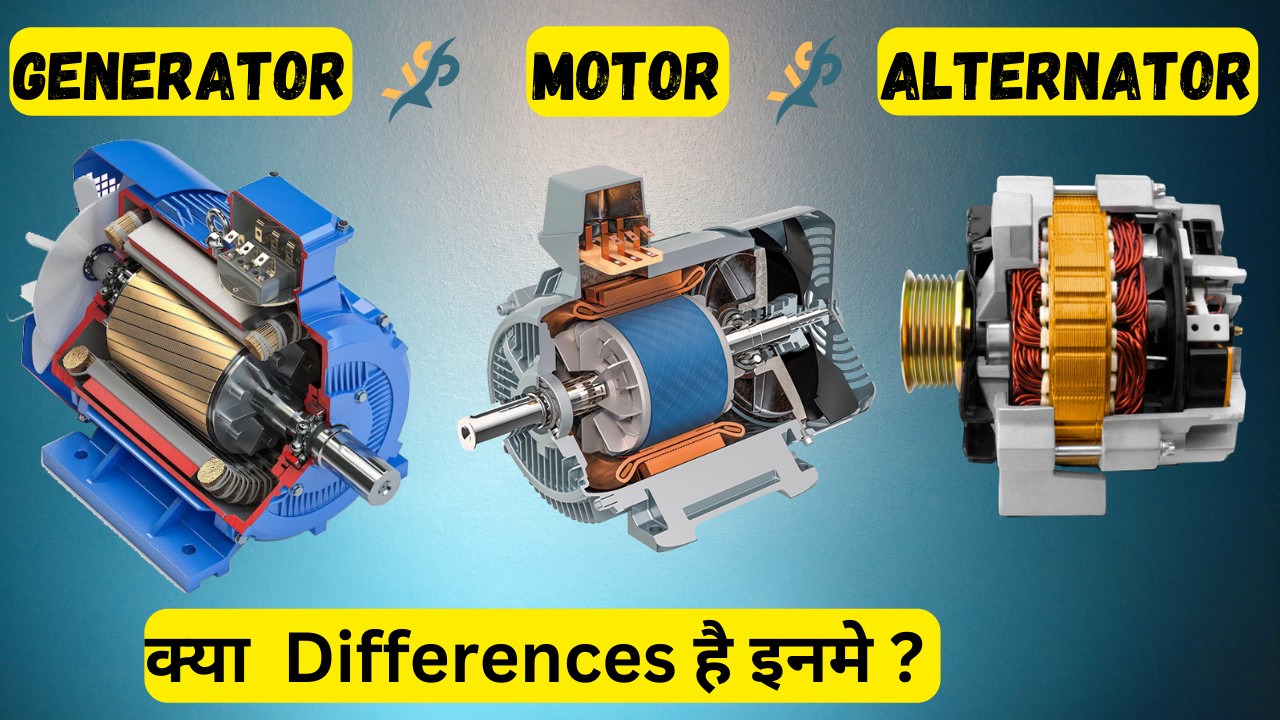

Motor VS Generator VS Alternator || How Generator, Motor And Alternator Works || In Hindi

AC MOTORS AND GENERATORS

5.0 / 5 (0 votes)