History of the Toyota Production System (TPS)

Summary

TLDRThe Toyota Production System (TPS) revolutionized manufacturing by emphasizing waste elimination and quality through intelligent automation (jidoka) and Just in Time manufacturing. Originating from Sakichi Toyota's innovations in loom technology, TPS evolved under Kiichiro Toyota, who integrated these principles into automobile production. Key figures like Taiichi Ohno further refined the system after World War II, establishing efficient processes that linked production with supply chains. The TPS gained global recognition, especially after Toyota's resilience during the 1973 oil crisis. Today, it remains a model of operational excellence, continuously evolving to enhance product quality and productivity.

Takeaways

- 😀 The Toyota Production System (TPS) focuses on eliminating waste to produce high-quality products efficiently.

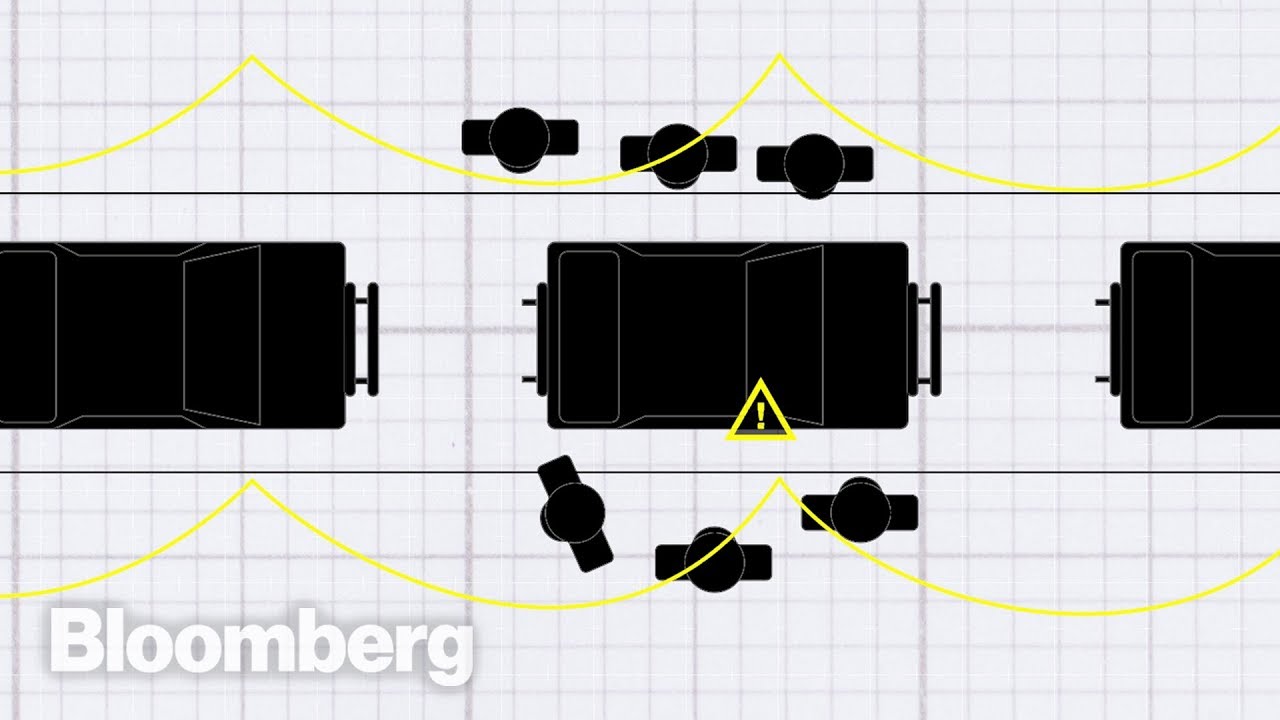

- 🔧 Intelligent automation, known as Jidoka, enhances manufacturing by allowing machines to detect problems and stop automatically.

- 📅 Just-in-Time (JIT) manufacturing aims to produce only what is needed, when it is needed, and in the required amount.

- 🚗 Sakichi Toyota's innovations in loom technology laid the foundation for the development of the Toyota Production System.

- 🌍 The TPS gained global recognition after the oil crisis of 1973, demonstrating resilience and efficiency compared to other automakers.

- 🤝 The joint venture between Toyota and General Motors in the United States showcased successful industrial cooperation and quality manufacturing.

- 📈 TPS principles have evolved but remain centered on continuous improvement and quality assurance in every production phase.

- 💡 The combon system efficiently manages inventory, ensuring that parts are delivered precisely when needed to reduce waste.

- ⚙️ Employees play a critical role in maintaining quality through their own initiatives to implement Jidoka measures on the assembly line.

- 🌟 Toyota's commitment to enhancing the quality of life through innovative manufacturing practices continues to influence the automotive industry.

Q & A

What is the primary focus of the Toyota Production System?

-The Toyota Production System primarily focuses on eliminating waste and providing quality products in a timely manner through intelligent automation and Just in Time manufacturing.

Who was Sakichi Toyota, and what significant invention did he create?

-Sakichi Toyota was the founder of the Toyota group, and he created the world's first high-speed loom that improved weaving efficiency significantly by eliminating manual oversight.

What is Jidoka, and how does it relate to automation in manufacturing?

-Jidoka, or intelligent automation, refers to the ability of machines to detect problems and stop working when an issue occurs, ensuring quality and reducing the need for constant human supervision.

How did Kichiro Toyota contribute to the automotive industry?

-Kichiro Toyota, Sakichi's son, played a crucial role in transitioning Toyota from loom manufacturing to automobile production by establishing Toyota Automatic Loom Works and developing the first passenger car prototype in 1935.

What is Just in Time manufacturing, and why is it important?

-Just in Time manufacturing is a strategy that aims to eliminate waste by producing only what is needed, when it is needed, and in the amount needed, enhancing efficiency and reducing inventory costs.

What challenges did Toyota face after World War II, and how did they address them?

-After World War II, Toyota faced significant challenges in productivity compared to the U.S. automotive industry. They addressed this by implementing Taiichi Ohno's Just in Time system and focusing on value-added productivity.

What role did Taiichi Ohno play in the development of the Toyota Production System?

-Taiichi Ohno was assigned to develop a more efficient production system that integrated Jidoka and Just in Time concepts, transforming Toyota's operations and boosting productivity.

How did the oil crisis of 1973 affect Toyota?

-The oil crisis of 1973 highlighted the effectiveness of the Toyota Production System, allowing Toyota to recover more quickly than its competitors and gaining global recognition for its efficient practices.

What was the significance of the joint venture between Toyota and General Motors?

-The joint venture established in 1984 between Toyota and General Motors was significant as it overcame cultural and language barriers, becoming a model for industrial cooperation and achieving high-quality production standards.

How does the Toyota Production System continue to evolve today?

-The Toyota Production System continues to evolve by adapting to changing needs and circumstances while maintaining its fundamental principles of Jidoka and Just in Time manufacturing to enhance quality and productivity.

Outlines

Этот раздел доступен только подписчикам платных тарифов. Пожалуйста, перейдите на платный тариф для доступа.

Перейти на платный тарифMindmap

Этот раздел доступен только подписчикам платных тарифов. Пожалуйста, перейдите на платный тариф для доступа.

Перейти на платный тарифKeywords

Этот раздел доступен только подписчикам платных тарифов. Пожалуйста, перейдите на платный тариф для доступа.

Перейти на платный тарифHighlights

Этот раздел доступен только подписчикам платных тарифов. Пожалуйста, перейдите на платный тариф для доступа.

Перейти на платный тарифTranscripts

Этот раздел доступен только подписчикам платных тарифов. Пожалуйста, перейдите на платный тариф для доступа.

Перейти на платный тарифПосмотреть больше похожих видео

Modelo Toyota de Produção - Just In Time & Kanban

⚙ Lean Manufacturing | A pursuit of perfection

How Toyota Changed The Way We Make Things

An Introduction To The Toyota Production System

Toyota’s Lean Supply Chain: The Secret Behind JIT Manufacturing Success | MBA Case study analysis

Toyota Material Handling | The Toyota Production System (TPS)

5.0 / 5 (0 votes)