How to replace a Motor Mount or Transmission Mount

Summary

TLDRIn this informative video, ChrisFix demonstrates how to replace worn-out engine and transmission mounts on a Ford van. He walks viewers through the process of diagnosing bad mounts, removing the old ones, and installing new parts with detailed instructions. Key tools, safety tips, and techniques are covered, including the use of penetrating fluid, a jack, and thread lock. The video ends with a test showing the engine's improved stability after the new mounts are installed, reducing excessive movement during gear shifts. Perfect for DIY car enthusiasts, this tutorial provides a clear, step-by-step guide to a successful motor mount replacement.

Takeaways

- 😀 Diagnosing engine mount problems: Shifting from Park to Reverse or Drive may cause engine movement, indicating worn-out mounts.

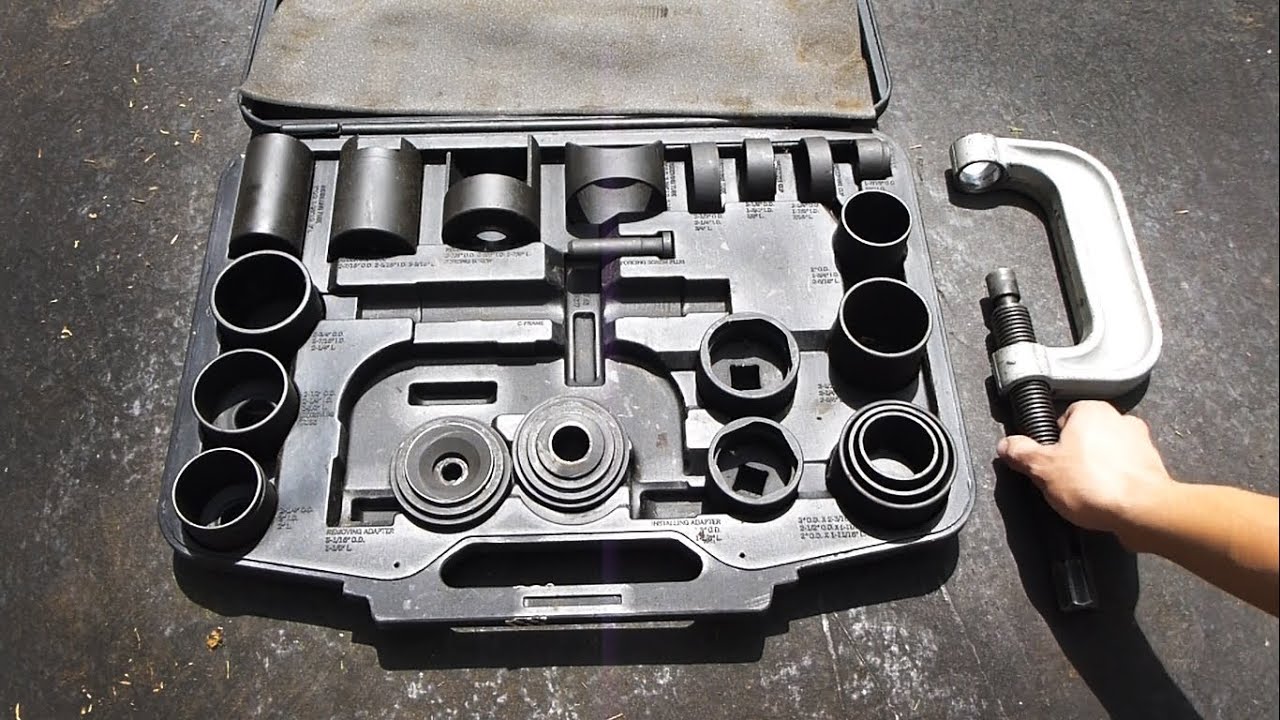

- 🛠️ Tools required for the task: Different sockets, extensions, ratchets, hammer, pry bar, wrenches, thread lock, jack stands, and a bottle jack.

- 🚗 Identifying engine and transmission mounts: The van has three engine mounts and two transmission mounts that need attention.

- 💡 Penetrating fluid: Apply penetrating fluid to the bolts before attempting to remove them, as the bolts are old and difficult to loosen.

- 🔧 Using extended leverage: If a wrench isn’t long enough, combine two wrenches to create extra torque for loosening tough bolts.

- 🧰 Jacking up the engine: Use a solid block of the transmission for jacking, and avoid jacking on the oil pans to prevent damage.

- 🛠️ Removing the engine mount: After loosening all bolts, jack the engine or transmission up to relieve pressure and allow the mount to be removed.

- ⚙️ Comparing new vs. old mounts: Ensure that the new engine mount looks similar to the old one before installation.

- 🔒 Thread locker application: Apply thread lock to bolts to ensure that they do not loosen over time due to vibrations.

- 🔨 Reinstalling the new mount: Carefully align the new mount, tighten the bolts, and lower the engine to secure the new mount in place.

- 💪 Final testing: After the new engine mount is installed, check for reduced engine shaking and movement, ensuring a stable engine operation.

Q & A

What are the signs that an engine mount needs to be replaced?

-Signs of a bad engine mount include excessive engine movement when shifting between Park, Reverse, or Drive, and noticeable vibrations or rocking of the engine.

What tools are required to replace an engine or transmission mount?

-You'll need a ratchet with various sized sockets, breaker bar, extensions, hammer, pry bar, flat screwdriver, open-ended wrenches, thread lock, jack stands, a jack, and some wood to protect the engine.

Why is it important to use penetrating fluid on the bolts?

-Penetrating fluid helps loosen rusted or stuck bolts, making it easier to remove them, especially since engine and transmission mounts can be under significant pressure.

What should you avoid when jacking up the engine or transmission?

-Avoid jacking up the oil pans (either transmission or engine oil pan), as they are not designed to support the vehicle's weight and can cause damage.

How do you safely lift the engine or transmission for mount replacement?

-Use a jack with a piece of wood to support the engine or transmission. Make sure to lift it from a solid area, such as the metal block on the transmission, not the oil pan.

What is the purpose of thread lock when installing the new mount?

-Thread lock ensures that the bolts remain tightly secured, preventing them from loosening over time due to vibrations from the engine or transmission.

Why should you compare the new mount with the old one before installation?

-Comparing the old and new mounts ensures they are identical in shape and size, preventing incorrect installations that could cause further issues.

What should you do if the new motor mount is slightly taller than the old one?

-If the new mount is taller, you can jack up the engine or transmission a little more to ensure it fits and aligns properly before bolting it into place.

How do you ensure the bolts are properly tightened?

-Tighten all bolts manually and then torque them to the recommended specification (90-100 ft-lb) using a torque wrench. If you can't access a torque wrench, tighten as much as possible manually.

What are the differences between engine mounts and transmission mounts?

-Engine mounts support the engine, while transmission mounts secure the transmission. Though the process of replacing both is similar, they are attached to different components (engine vs. transmission).

Outlines

Cette section est réservée aux utilisateurs payants. Améliorez votre compte pour accéder à cette section.

Améliorer maintenantMindmap

Cette section est réservée aux utilisateurs payants. Améliorez votre compte pour accéder à cette section.

Améliorer maintenantKeywords

Cette section est réservée aux utilisateurs payants. Améliorez votre compte pour accéder à cette section.

Améliorer maintenantHighlights

Cette section est réservée aux utilisateurs payants. Améliorez votre compte pour accéder à cette section.

Améliorer maintenantTranscripts

Cette section est réservée aux utilisateurs payants. Améliorez votre compte pour accéder à cette section.

Améliorer maintenant5.0 / 5 (0 votes)