How to Press a Ball Joint

Summary

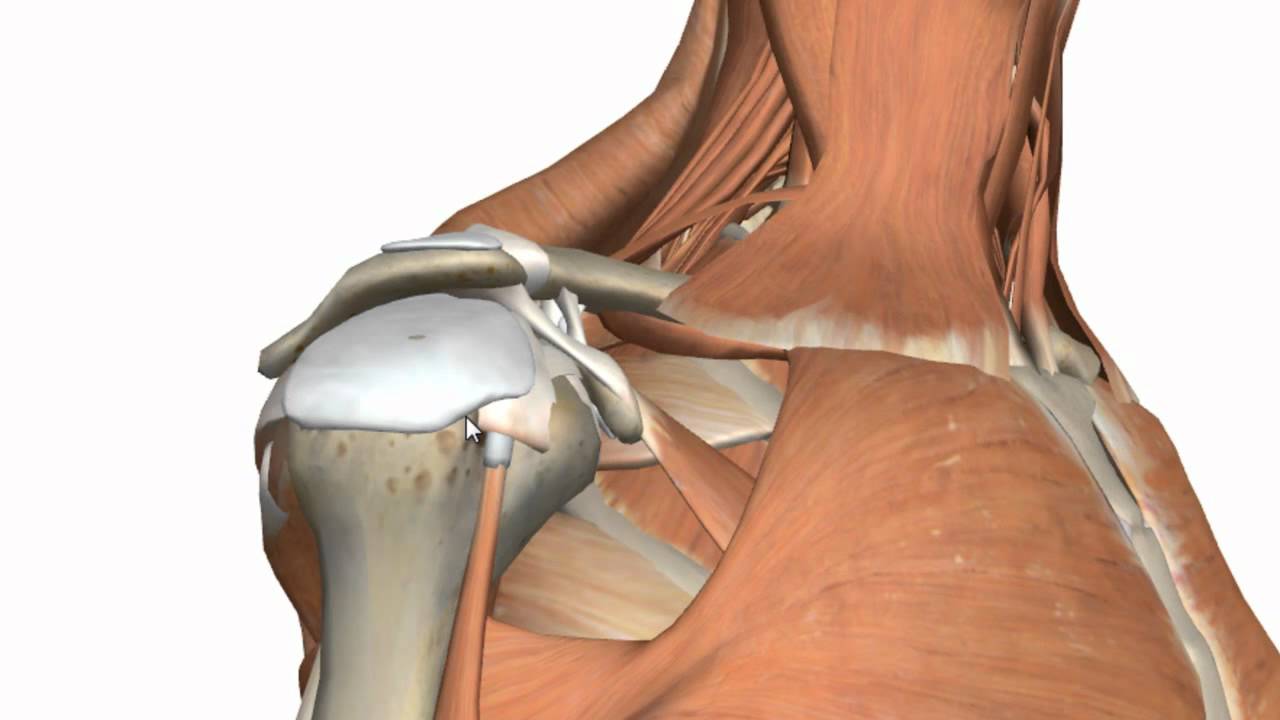

TLDRIn this tutorial, ChrisFix demonstrates how to press out and replace a ball joint using a ball joint press. He explains the importance of using the correct tools to avoid damaging the ball joint during removal and installation. The process includes removing a worn ball joint, cleaning the control arm, and using various adapters to ensure proper press alignment. ChrisFix also highlights the importance of greasing the new ball joint for long-term durability and provides tips on installation, including proper orientation and ensuring the snap ring fits securely.

Takeaways

- 😀 Ball joint presses can be rented for free at many auto parts stores like Vance Auto, Pep Boys, and AutoZone.

- 😀 The seat clamp of the ball joint press applies pressure on the ball joint without damaging the stud, focusing on the shoulder and top of the joint.

- 😀 Always remove the snap ring before pressing out the ball joint, using snap ring pliers or needle nose pliers, but be cautious as they can fly off.

- 😀 Clean the control arm area thoroughly with brake clean, a wire brush, and compressed air to avoid debris causing scratches during the press process.

- 😀 Use penetrating fluid like PB Blaster around the ball joint to help it come out more easily, especially if it’s stuck.

- 😀 When removing the ball joint, ensure the press tool is aligned properly so the pressure is applied straight to avoid damaging the control arm or joint.

- 😀 When pressing in a new ball joint, use the correct setup to press against the shoulder of the ball joint and avoid putting pressure on the stud or rubber boot.

- 😀 To press the new ball joint in, ensure the press setup surrounds the control arm and avoids direct contact with the joint’s stud.

- 😀 Always orient the new ball joint with the grease relief facing outward, away from brake rotors, to ensure proper lubrication during use.

- 😀 After pressing the new ball joint in, install the snap ring securely and check the ball joint for proper positioning before finishing the job.

- 😀 The ball joint press kit comes with specific adapters designed for both removal and installation, ensuring a secure fit for each step of the process.

Q & A

What is the primary purpose of the ball joint press?

-The ball joint press is used to press out and press in ball joints in a vehicle, allowing for the removal and installation of the ball joint without damaging the control arm or other components.

What safety precautions should be taken before using the ball joint press?

-Before using the ball joint press, ensure the area is clean and free of grit or dirt to prevent scratching the control arm. Using brake cleaner and compressed air helps clean the area. Additionally, it’s important to carefully remove the snap ring to avoid it flying off.

Why is it crucial not to put pressure on the ball joint stud during the pressing process?

-It’s essential not to put pressure on the ball joint stud because it can damage the stud, which would ruin the ball joint. The pressure should instead be placed on the shoulder of the ball joint and the top part of the joint to avoid damage.

What should be done if the press doesn't have an adapter that fits the ball joint?

-If the press doesn't have an appropriate adapter, you need to look for a piece that completely surrounds the ball joint but does not touch it, while also making sure the top of the press touches the control arm. The correct fit is crucial for successful removal or installation.

Why is penetrating fluid recommended when pressing out the ball joint?

-Penetrating fluid helps loosen up any corrosion or dirt around the ball joint, making it easier to remove. It also helps lubricate the area and can make the pressing process smoother.

What is the function of the C-clamp in the ball joint press?

-The C-clamp is used to apply the necessary force to press down on the ball joint or press the new ball joint in. It should be properly aligned and positioned to ensure it presses straight without causing damage.

How can you tell when the ball joint is successfully pressed out?

-You can tell the ball joint has been successfully pressed out when it pops free, often accompanied by a noticeable release or the ball joint moving downwards. It is also helpful to monitor for penetrating fluid leakage as an indication of progress.

Why is it important to press the new ball joint in the correct orientation?

-The new ball joint needs to be installed in the correct orientation because the ball joint typically has a grease relief that should face away from the brake rotors. This ensures proper lubrication and functioning of the joint.

What role does the jack play when installing a new ball joint?

-The jack is used to lift the control arm and allow sufficient clearance to properly press the ball joint into place. Lifting the control arm also helps with the alignment of the press and the ball joint for a smooth installation.

What is the significance of using a ball joint with a grease fitting?

-A ball joint with a grease fitting is beneficial because it allows you to lubricate the ball joint over time, reducing wear and tear. This extends the life of the ball joint and helps prevent grit and grime buildup inside the joint.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade Now5.0 / 5 (0 votes)