Polymer Viscoelasticity

Summary

TLDRThis video explains viscoelasticity in polymeric materials, highlighting their unique behavior of exhibiting both elastic and viscous deformation. It discusses the distinction between recoverable elastic deformation and permanent viscous deformation, illustrated through real-world examples. The video further explores the molecular mechanisms behind polymer behavior under stress, including chain mobility and entanglement. It introduces three primary viscoelastic models—Maxwell, Kelvin-Voigt, and Standard Linear Viscoelastic models—each with its applications and limitations. This comprehensive overview serves as a valuable resource for understanding the complexities of polymer deformation, particularly for exam preparation.

Takeaways

- 😀 Viscoelasticity combines elastic and viscous deformation, allowing materials to exhibit characteristics of both solids and liquids.

- 😀 Elastic deformation is recoverable, meaning materials return to their original shape when the force is removed, while viscous deformation leads to permanent changes.

- 😀 Polymers can behave like liquids despite being solid at room temperature due to their long-chain molecular structure.

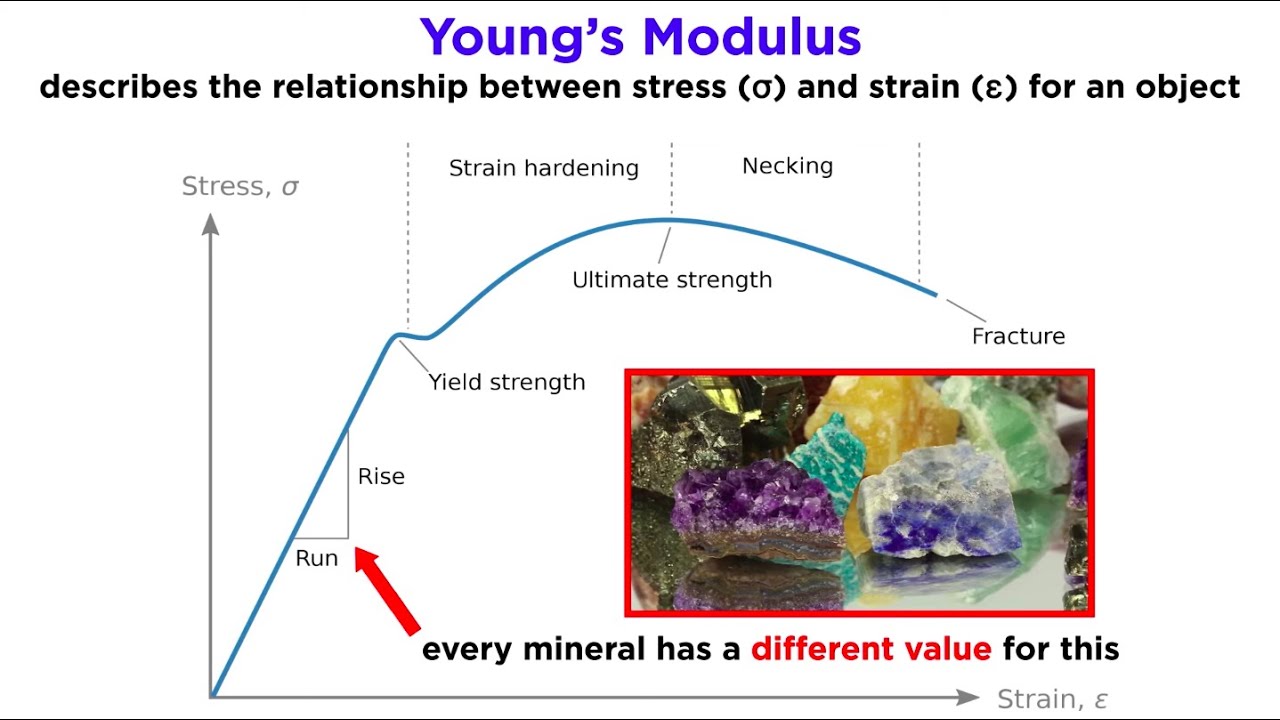

- 😀 The deformation behavior of polymers includes an initial linear increase in stress with strain, followed by a yield point leading to permanent deformation.

- 😀 Molecular interactions in polymers involve chemical forces and entanglement points, which contribute to their viscoelastic properties.

- 😀 Polymer chains exhibit mobility at different timescales, influencing their time-dependent deformation characteristics.

- 😀 Under external stress, polymer chains can align, stretch, and experience changes that affect their morphology.

- 😀 The Maxwell model describes viscoelastic behavior with a spring and dashpot in series, suitable for understanding soft solids.

- 😀 The Kelvin-Voigt model features a spring and dashpot in parallel, effective for modeling creep but less accurate for stress relaxation.

- 😀 The Standard Linear Viscoelastic (SLV) model combines aspects of both previous models to accurately predict creep and stress relaxation behaviors.

Q & A

What is viscoelasticity?

-Viscoelasticity is a type of deformation that involves both elastic and viscous behavior in materials.

How does elastic deformation differ from viscous deformation?

-Elastic deformation is recoverable, allowing the material to return to its original shape after the force is removed, whereas viscous deformation is non-recoverable and results in permanent change.

What are some examples of elastic and viscous deformation?

-An example of elastic deformation is stretching a rubber band, while viscous deformation can be seen in the flow of fluids like water or honey.

Why do polymers exhibit both solid and liquid-like deformation behaviors?

-Polymers are solid at room temperature but can deform like liquids due to their long-chain molecular structure, which allows for significant chain motion under stress.

What happens to a polymer when stress is applied?

-Initially, at small deformations, stress increases linearly with strain in the elastic region. Beyond the yield point, the polymer undergoes permanent deformation.

What key factors contribute to the viscoelastic behavior of polymers?

-Key factors include the chemical nature of the polymer chain, molecular weight, percent crystallinity, and the type of deformation experienced.

What are the three common models used to describe viscoelastic behavior?

-The three common models are the Maxwell model, the Kelvin-Voigt model, and the standard linear viscoelastic model.

How does the Maxwell model explain viscoelastic behavior?

-In the Maxwell model, a spring and dashpot are connected in series, representing elastic and viscous deformation, respectively, allowing for a simple relationship between stress and strain.

What limitations does the Kelvin-Voigt model have?

-While the Kelvin-Voigt model accurately predicts strain decrease over time under constant stress, it is less accurate in modeling stress relaxation.

Why is understanding viscoelastic behavior important in material design?

-Understanding viscoelastic behavior is crucial for predicting material performance under different conditions, which is essential in designing load-bearing structures.

Outlines

Cette section est réservée aux utilisateurs payants. Améliorez votre compte pour accéder à cette section.

Améliorer maintenantMindmap

Cette section est réservée aux utilisateurs payants. Améliorez votre compte pour accéder à cette section.

Améliorer maintenantKeywords

Cette section est réservée aux utilisateurs payants. Améliorez votre compte pour accéder à cette section.

Améliorer maintenantHighlights

Cette section est réservée aux utilisateurs payants. Améliorez votre compte pour accéder à cette section.

Améliorer maintenantTranscripts

Cette section est réservée aux utilisateurs payants. Améliorez votre compte pour accéder à cette section.

Améliorer maintenantVoir Plus de Vidéos Connexes

5.0 / 5 (0 votes)